Steel tube rolling process

A process and steel pipe technology, applied in the field of steel pipe rolling process, can solve problems such as difficulty, and achieve the effects of high utilization rate, improved production efficiency, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

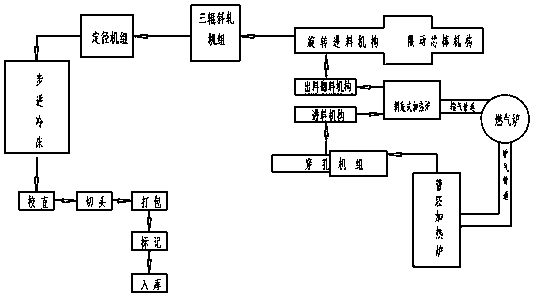

[0024] Example: combined as figure 1 As shown, the steel pipe rolling process example of the present invention is further described: the steel pipe rolling process is characterized in that it comprises the steps:

[0025] 1) Heating, heating the tube billet with a diameter of 50-100 mm to above 1150 °C in a heating furnace;

[0026] 2), piercing, the heated tube blank is pierced by a piercing machine to make a capillary tube with an outer diameter of 53-103 mm;

[0027] 3) Second soaking, sending the perforated capillary into the inclined-bottom heating furnace for short-term heating;

[0028] 4) Rolling, the capillary tube after the second soaking is put on the stop mandrel, and then through the three-roll skew rolling mill for diameter reduction, wall reduction, and extension rolling to form a blank tube, which is relatively , diameter reduction is 10-15 mm, wall reduction is 0.5-1 mm, elongation rolling elongation is 1.2);

[0029] 5) Remove the tube, the unrolled tube a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com