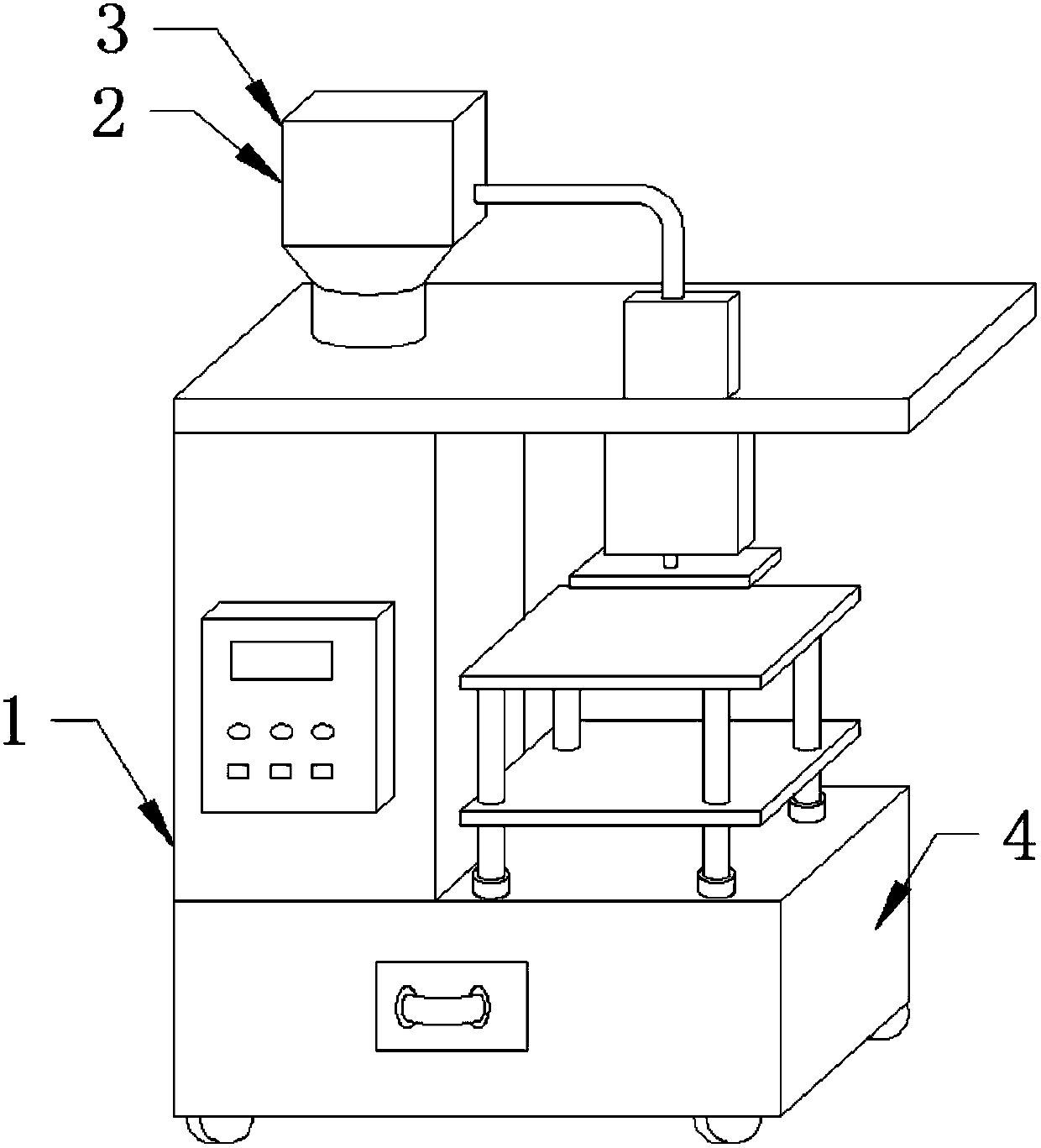

Core shooting machine convenient to disassemble

A core shooting machine and filter mechanism technology, applied in the field of core shooting machines, can solve the problems of motor, power supply and other equipment damage, inconvenient filter removal, poor heat dissipation efficiency of the motor, etc., to achieve easy operation, improve disassembly convenience, Highly functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

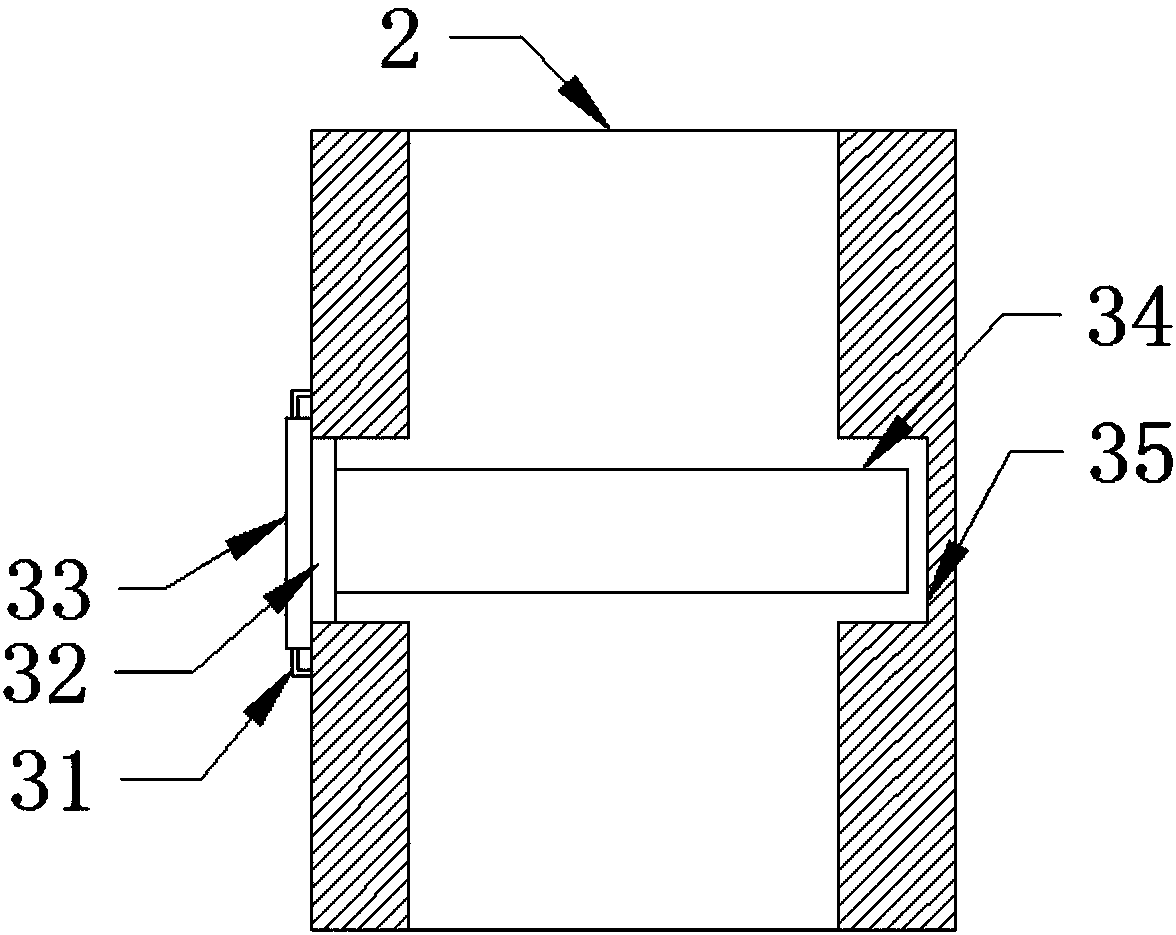

[0024] Specific implementation method: when the user needs to disassemble the filter screen 34, the user first turns the buckle 31 to take out the sealing cover 33, and a sealing plug is provided at the connection between the through hole 32 and the filter screen 34, and the sealing plug prevents the water from entering the feeding cylinder 2. The material leaks out through the through hole 32, the user takes out the sealing plug, the user takes out the filter screen 34 through the through hole 32, removes the impurities on the filter screen 34, and then puts the filter screen 34 into the groove 35. This design is convenient The user disassembles the filter screen 34, avoids the long-term accumulation of impurities on the filter screen 34 and causes blockage, solves the problem that the original core shooter does not have the function of conveniently disassembling the filter screen 34, and improves the convenience of disassembly of the present invention.

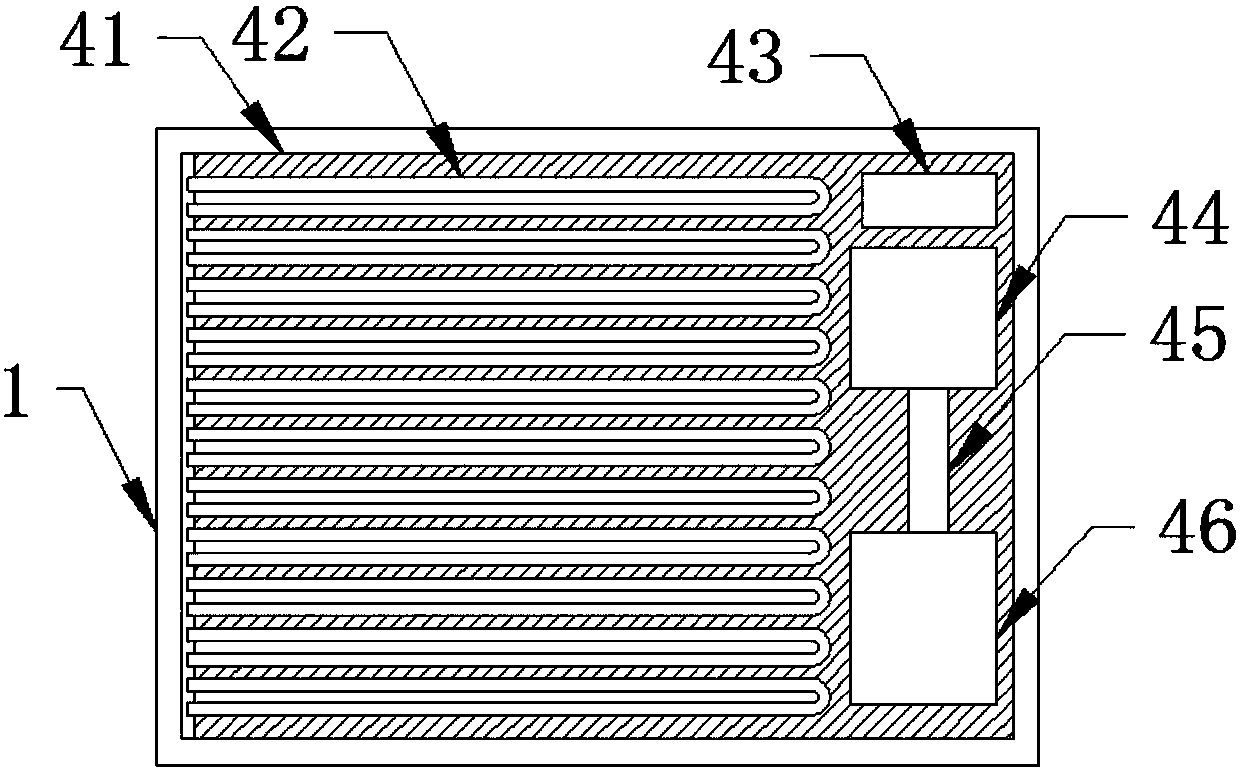

[0025] When the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com