An integrated laser additive manufacturing method for selective strengthening of titanium or titanium alloy

A technology of laser additive manufacturing and manufacturing method, which is applied in the integrated laser additive manufacturing of titanium or titanium alloy selective strengthening, and the field of titanium and titanium alloy surface modification, which can solve the problem of high crack tendency, high time cost and high strengthening cost. problem, to achieve the effect of low strengthening cost, good mechanical properties and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0027] The present invention is an integrated laser additive manufacturing method for selective strengthening of titanium or titanium alloy, comprising the following steps,

[0028] Step 1, fixing the substrate required for additive manufacturing on the workbench of the processing room.

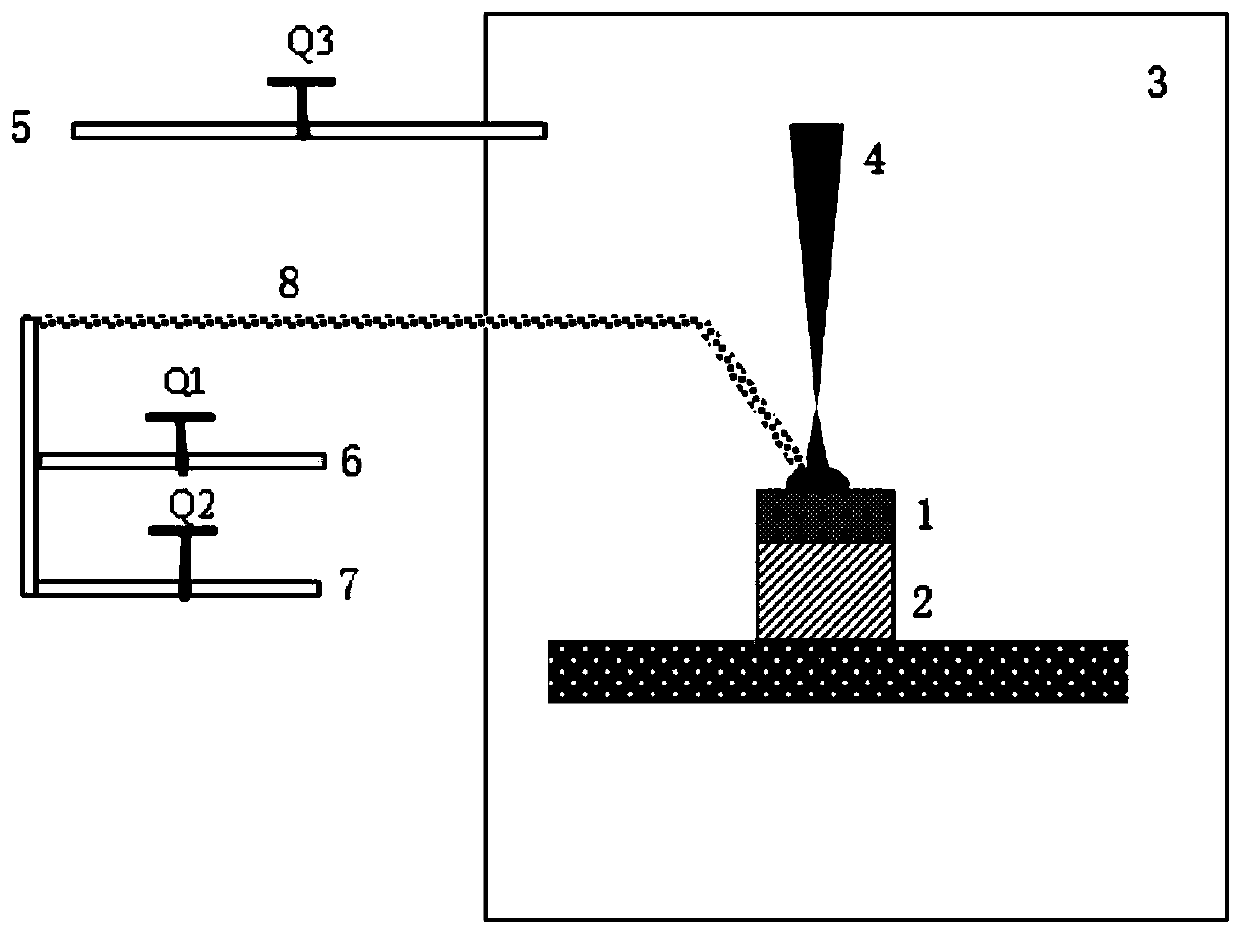

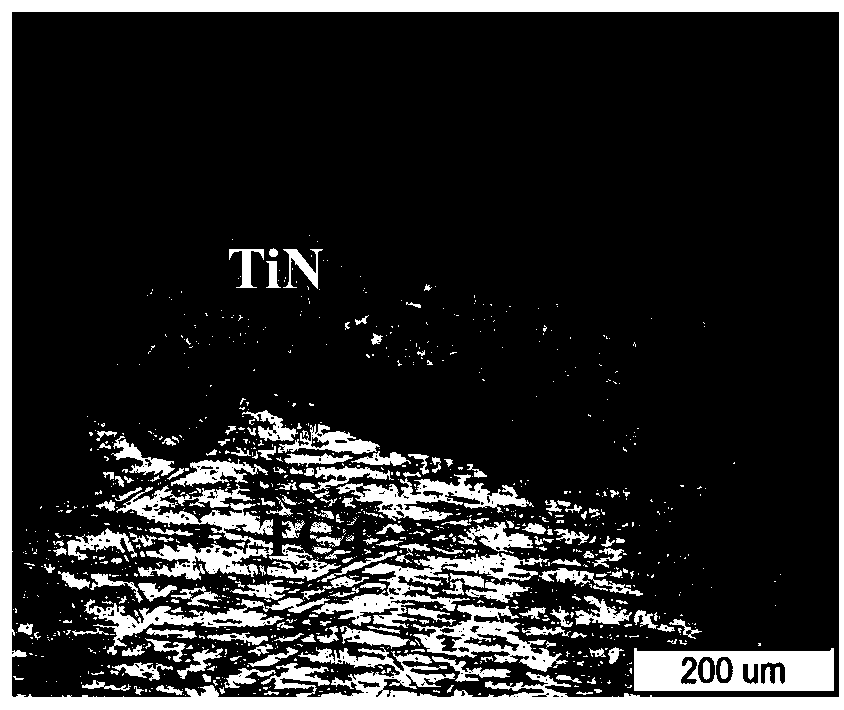

[0029] Step 2: Perform titanium or titanium alloy additive manufacturing in the processing chamber. During the additive manufacturing process, by changing the powder-carrying gas and laser lens shielding gas, the gas atmosphere at the molten pool is inert gas for non-enhanced area deposition or An inert gas containing 30% to 100% nitrogen is used for enhanced area deposition. Specifically, the layer-by-layer deposition method is adopted. When depositing to the area that needs to be strengthened, without cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com