Body chassis of 100% low-floor tram

A tram and low-floor technology, applied in the field of rail transit, can solve the problems of poor corrosion resistance, increased plate thickness, and low rigidity, and achieve the effects of simplified production process, good strength and rigidity, and good force transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

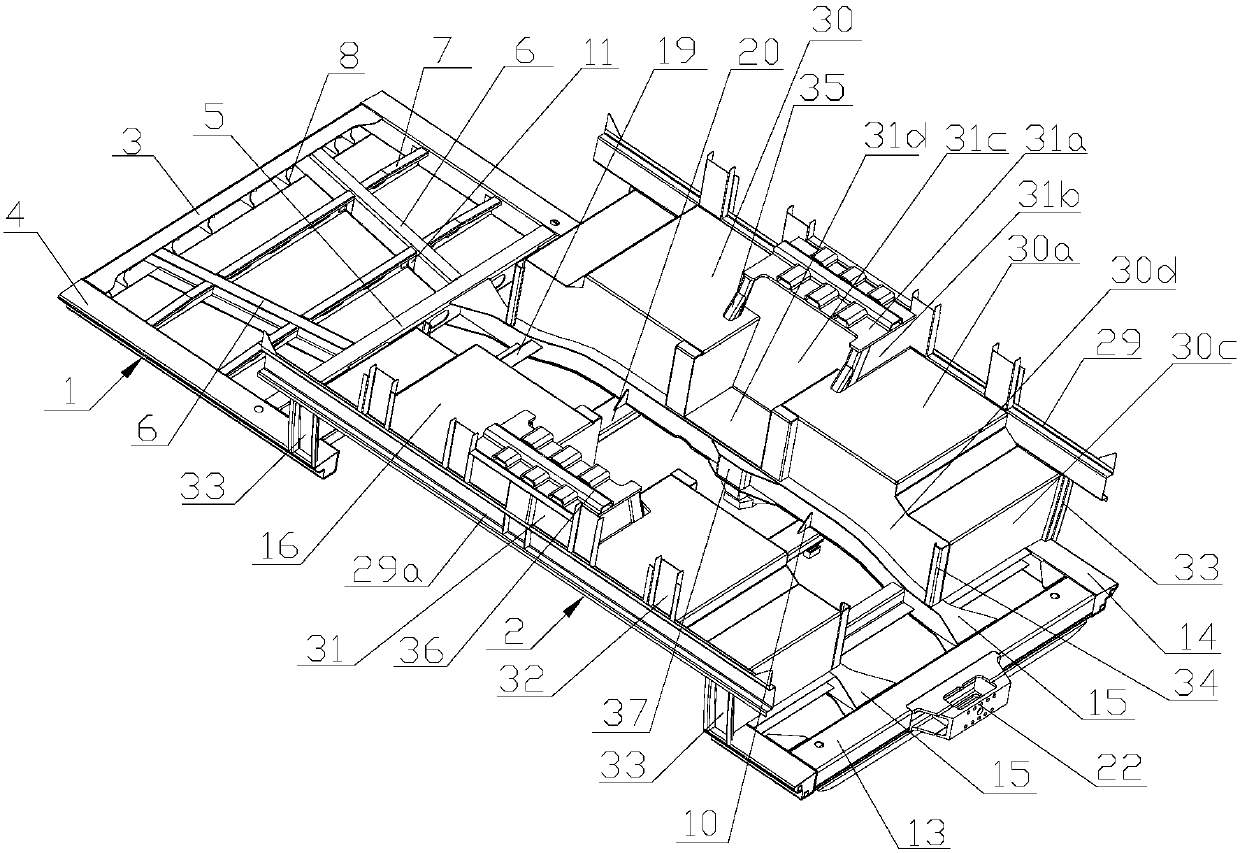

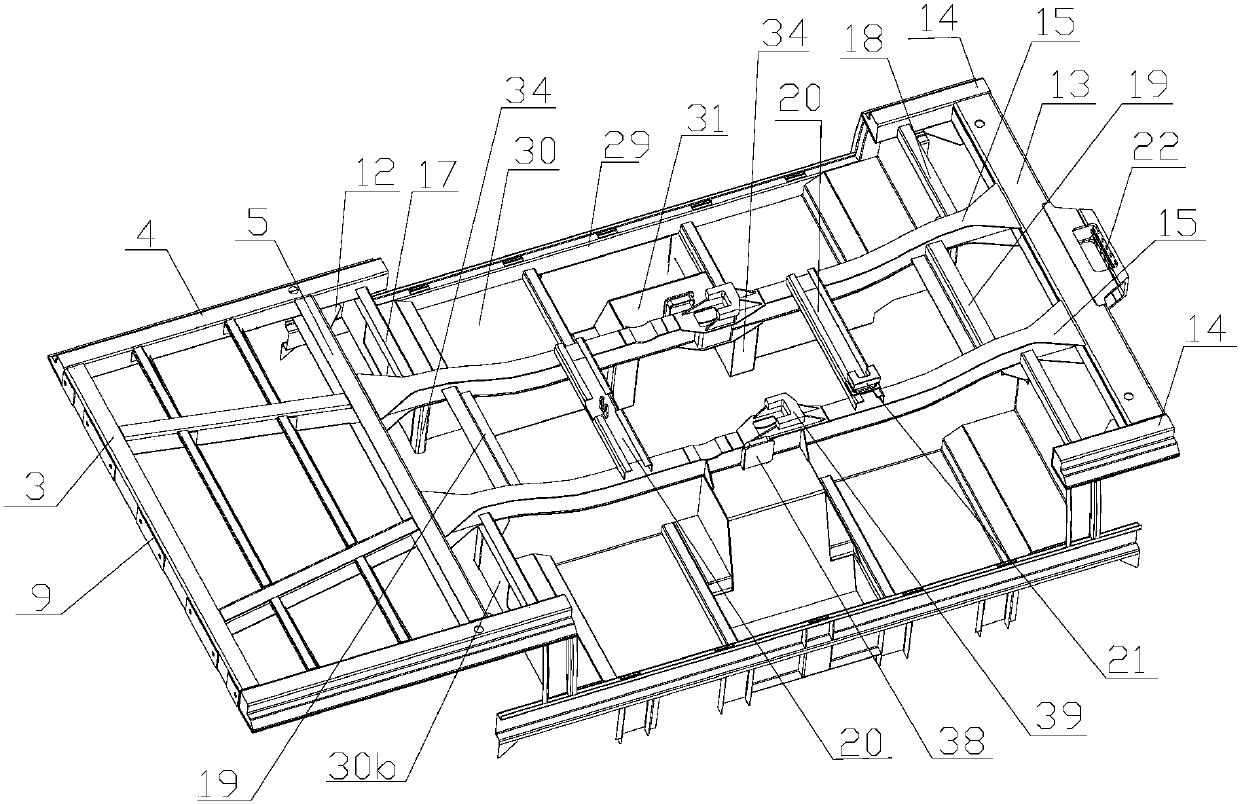

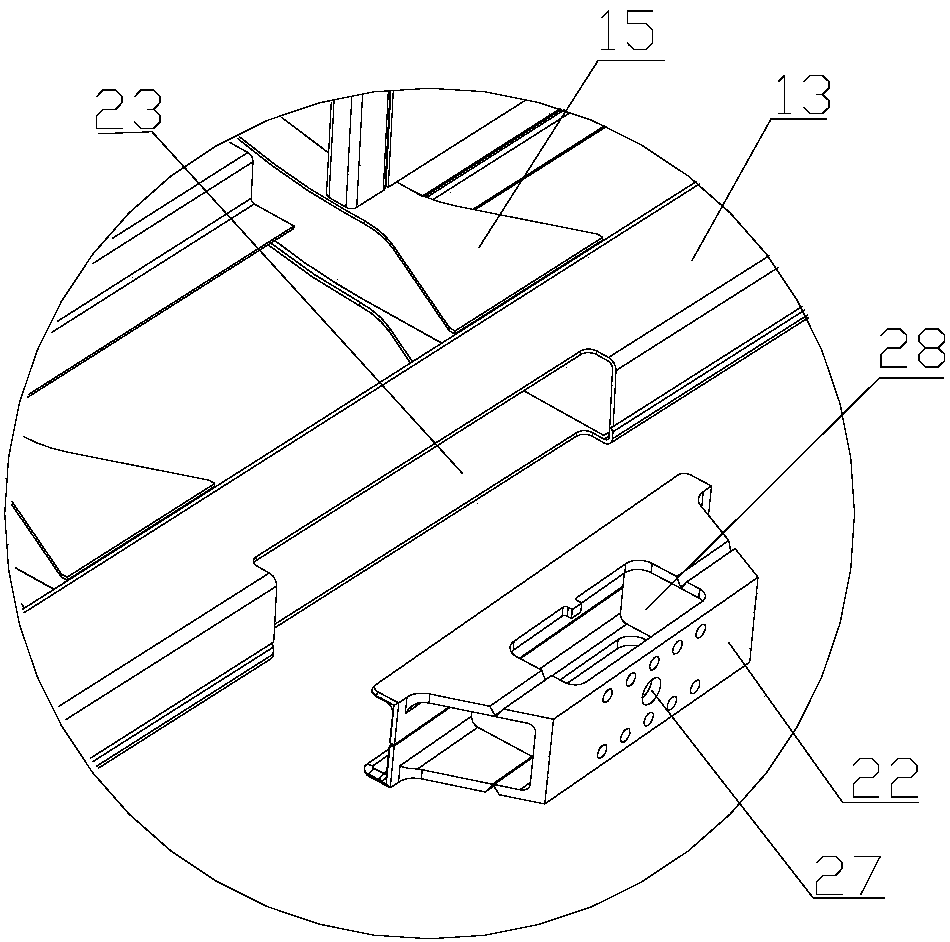

[0030] Such as figure 1 and figure 2 As shown, a kind of 100% low-floor tram car body chassis provided by the present invention, its front end is connected with driver's cab chassis, and the rear end is hinged between the car body chassis with the adjacent compartment. The underframe is assembled and welded by two parts, the front part 1 of the underframe connected with the driver's cab and the rear part 2 of the underframe located above the wheel set area of the bogie. In order to reduce the total weight of the underframe on the premise of ensuring the overall structural strength and rigidity of the underframe and meet the requirements of lightweight vehicles, in this embodiment, the materials of the front part 1 of the underframe and the rear part 2 of the underframe are preferably stainless steel materials .

[0031] Such as figure 1 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap