Tank body for bulk cement tank car

A technology for bulk cement and tanks, applied in packaging, underwater structures, transportation and packaging, etc., can solve the problems of low volume utilization, low unloading efficiency, high center of gravity, etc., and achieve large taper, fast inflation speed, and volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the drawings and embodiments, but they are not used to limit the scope of the present invention.

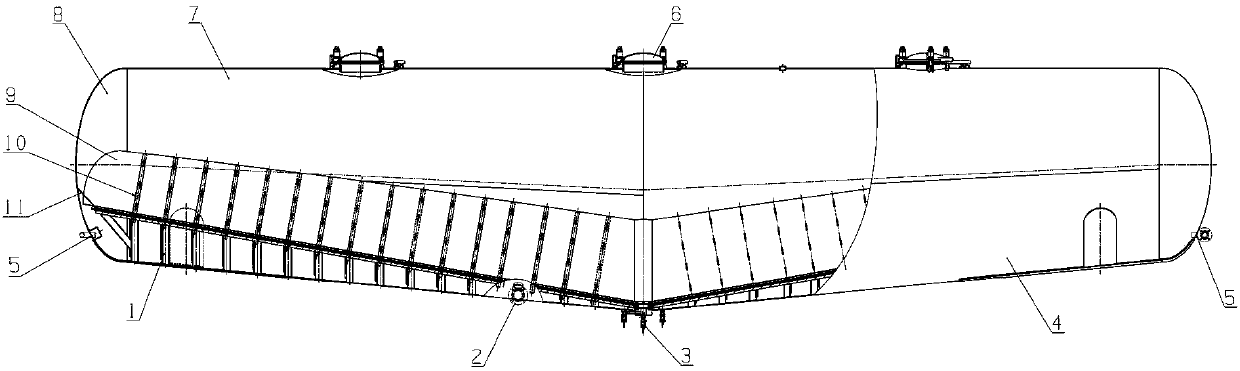

[0020] Such as figure 1 As shown, the tank of the present invention includes a fluidized bed device 1, a middle air inlet 2, a drain pipe 3, a lower tank plate 4, an end air inlet 5, a manhole device 6, an upper tank plate 7, a head 8, and a side plate 9. The side post 10, the end plate 11, the cylinder of the tank is welded together by the lower tank plate 4, the upper tank plate 7, and the head 8 into a straight cone inclined bottom structure, which has the characteristic of large taper. Three manholes are provided on the upper part of the cylinder for installing manhole devices, and a fluidized bed device 1 with a larger inclination angle is set at the bottom of the tank. The fluidized bed device 1 forms a sandwich-type air chamber structure together with the side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com