A method of strengthening the foundation with piles

A foundation and construction method technology, applied in the direction of sheet pile walls, foundation structure engineering, mechanical equipment, etc., can solve the problems of affecting the effect, affecting the size of the reaming, and reducing the impact force of rock and soil, so as to achieve not easy subsidence, accurate positioning, The effect of a large taper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

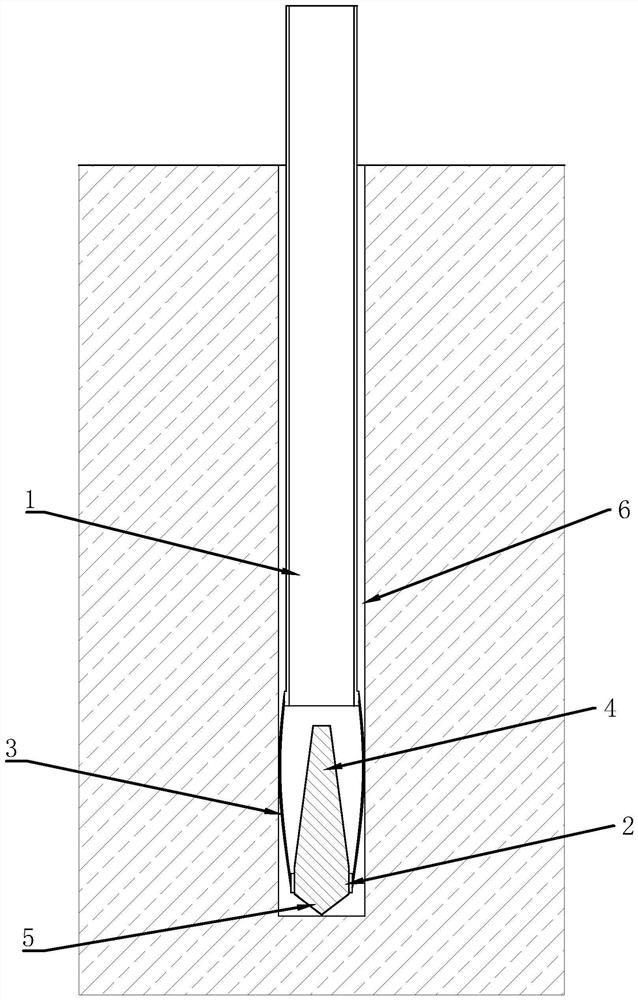

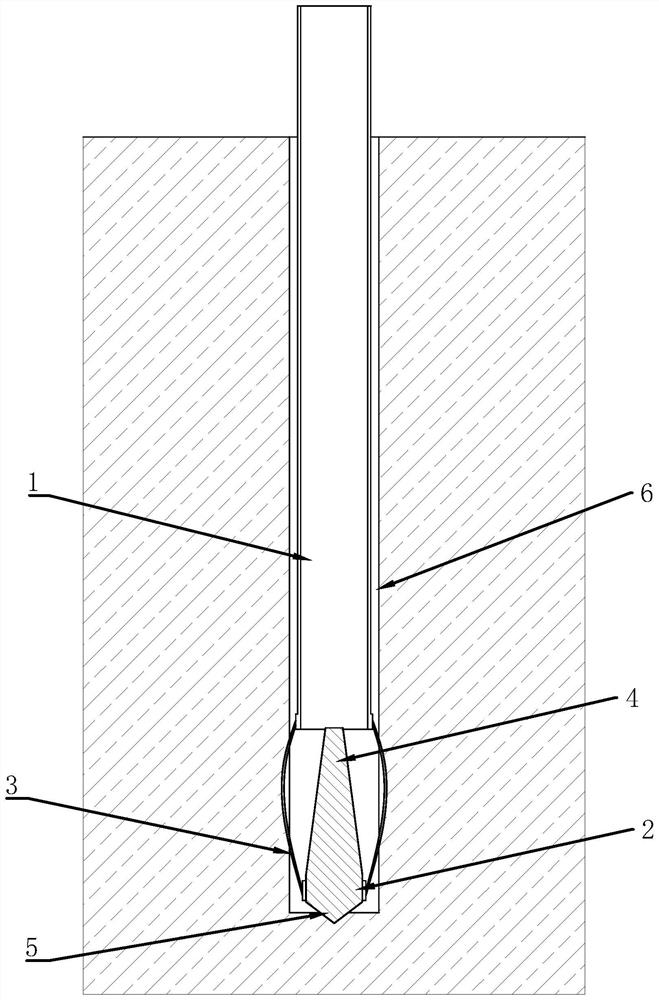

[0040] The protective layer is a polyurethane layer covering the web 3. Polyurethane layer is a high-strength plastic material, referred to as polyurethane

[0041] The width of the middle of the spoke 3 is smaller than the width of both ends. The spokes 3 are narrower in the middle and wider at the ends, making the blasting shock

[0046] According to needs, by pressing down the profiled pipe 1 while rotating the profiled pipe 1, and then pulling up the profiled pipe 1, the soil extraction is completed. Down type

[0049] The specific embodiments described herein are merely illustrative of the spirit of the invention. The technical field to which the present invention belongs

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com