Plastic pipe coiler

A tube coil and tube machine technology, which is used in thin material handling, filament transportation, transportation and packaging, etc., can solve the problems of inability to rewind and remove plastic tubes easily, and achieve novel design and structure. Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

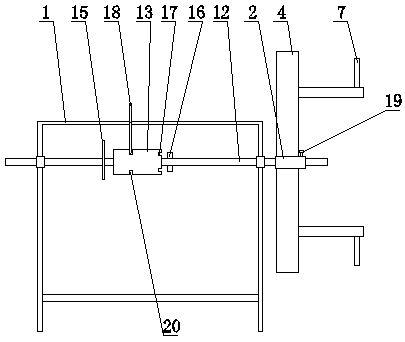

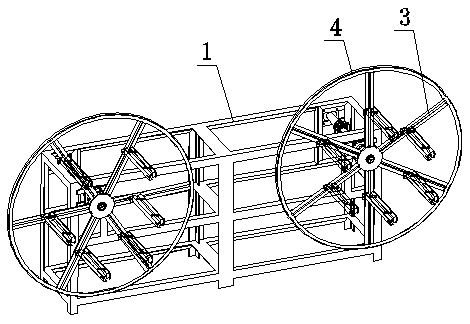

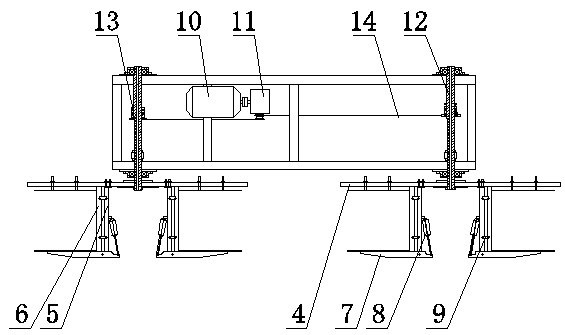

[0020] The plastic pipe coiler is composed of a frame 1, a power mechanism and a hose reel, and the frame 1 is a rectangular frame body. One side of the frame 1 is equipped with a hose reel in a front and rear parallel shape. The hose reel is composed of a core tube 2, a support rod 3, an outer wheel 4 and a stopper. A plurality of support rods 3 are installed radially on the circumference of the core tube 2. The ends of the support rods 3 are equipped with an outer wheel 4, and the outer wheel 4 and The support rod 3 between the core tubes 2 is fixed with a limiter; the limiter is composed of a mounting rod 5, an expansion rod 6, a limit ejector rod 7 and a pneumatic cylinder 8, and one side of the mounting rod 5 passes through the hinge plate 9 An expansion strut 6 is installed movable, and the end of the installation rod 5 is movably installed with a limit ejector rod 7 through a pin. Push rod 7 is connected.

[0021] A power mechanism is arranged in the middle part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com