Magnetic suspension low-frequency shock absorber

A technology of magnetic suspension and shock absorber, applied in the direction of spring/shock absorber, magnetic spring, vibration suppression adjustment, etc., can solve the problem of lack of good vibration isolation effect, achieve ideal vibration isolation effect, increase damping coefficient, practicality strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

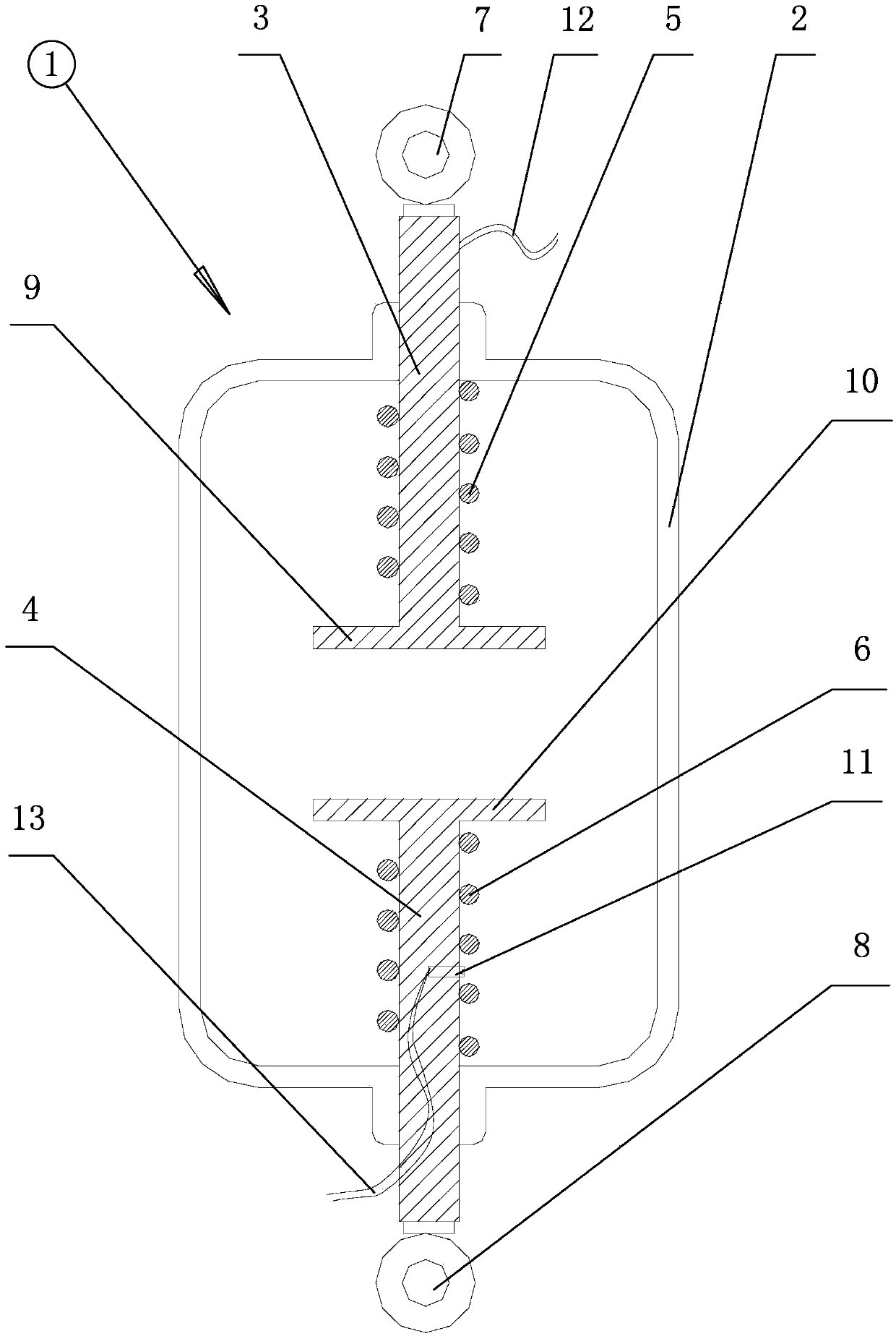

[0019] The technical solution adopted in the present invention is to use the functional relationship between the magnetic force and the iron core rod inside the wire rubber sleeve 2 to change the magnitude of the excitation current through the control and adjustment system to realize the control of the magnetic force of the magnetic pole to damp the shock absorber. The size of the coefficient is adjusted by feedback to meet the control requirements for vibrations of different amplitudes and frequencies.

[0020] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

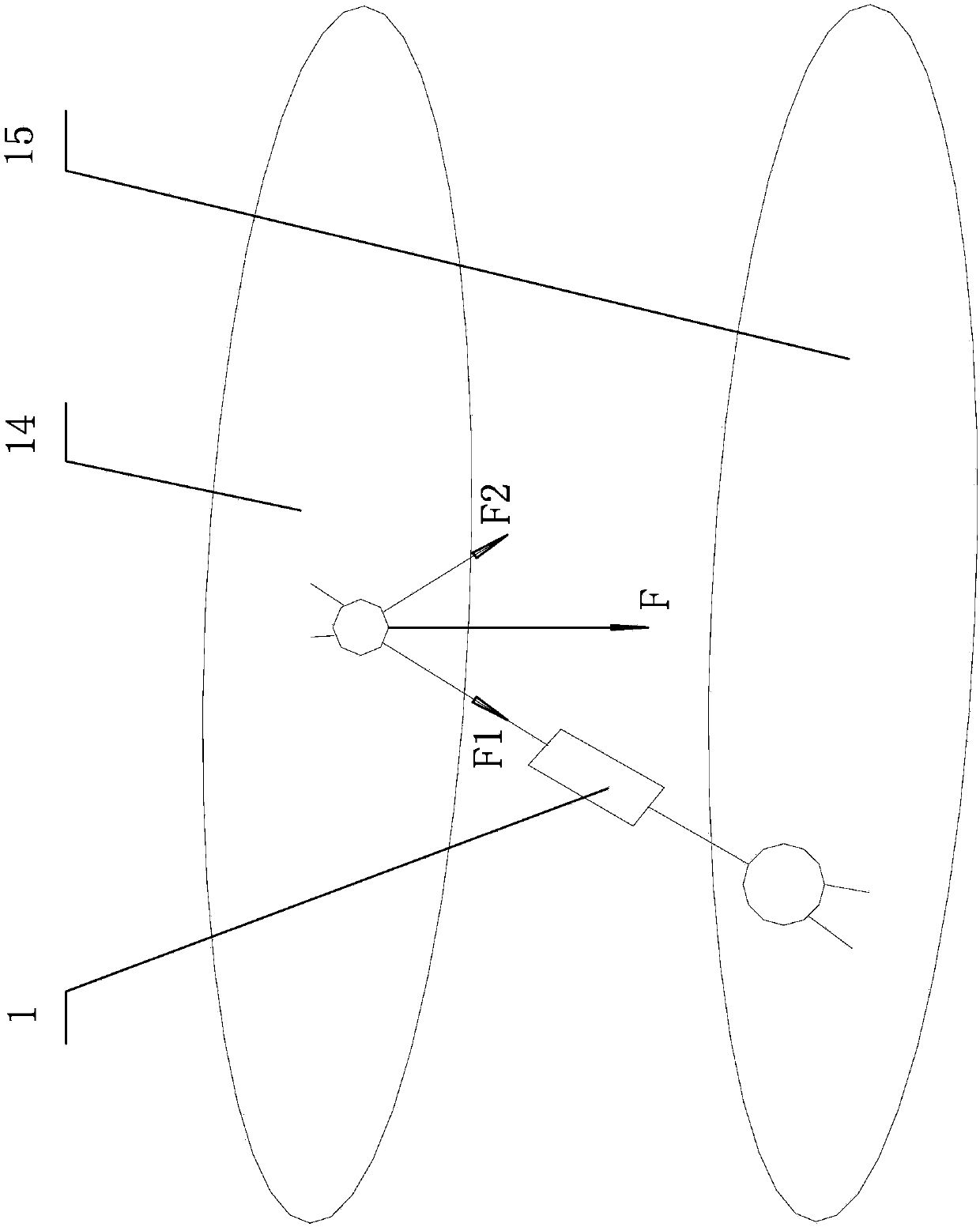

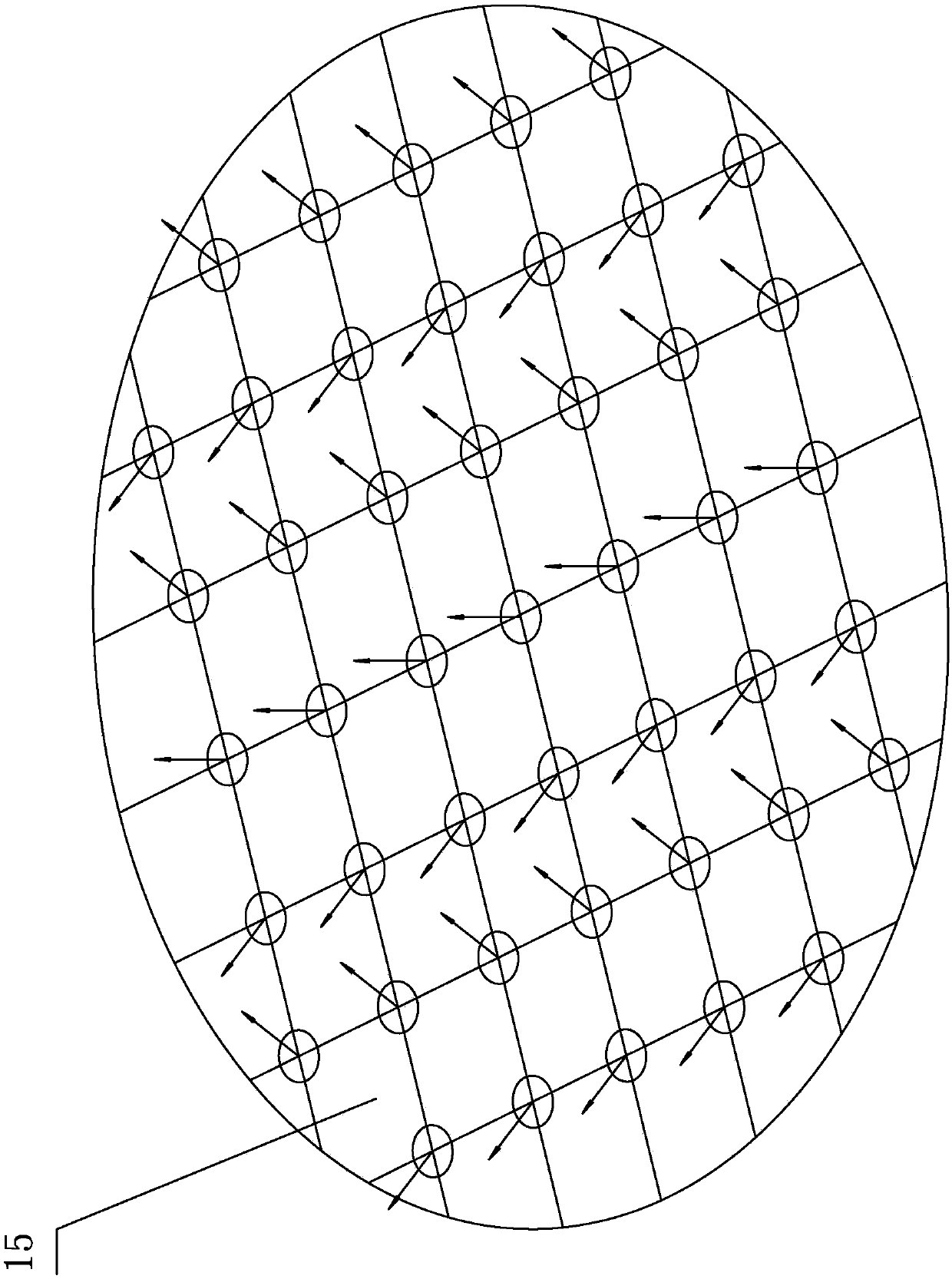

[0021] The magnetic suspension low-frequency shock absorber of the present invention includes a shock absorbing unit group installed between the upper and lower bases 14 and 15, and the shock absorbing unit group includes several shock absorbing units 1 .

[0022] Each damping unit 1 includes a wire rubber sleeve 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com