Pipeline robot detection device and pipeline fault detection method

A pipeline robot and detection device technology, which is applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the problems of inability to accurately detect pipeline operating conditions and limited detection range of detection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

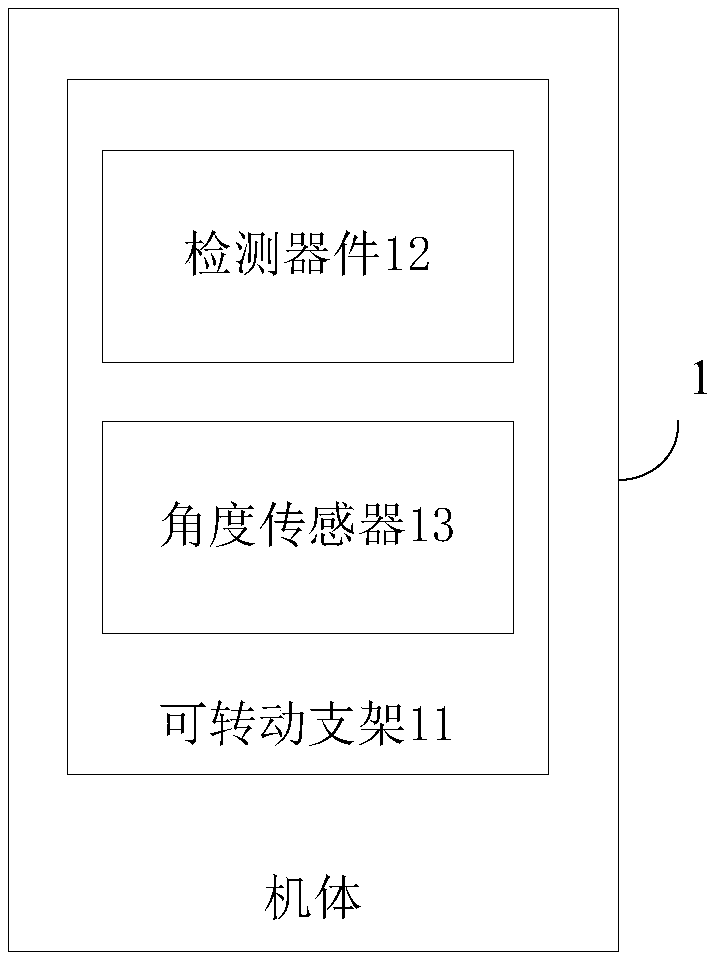

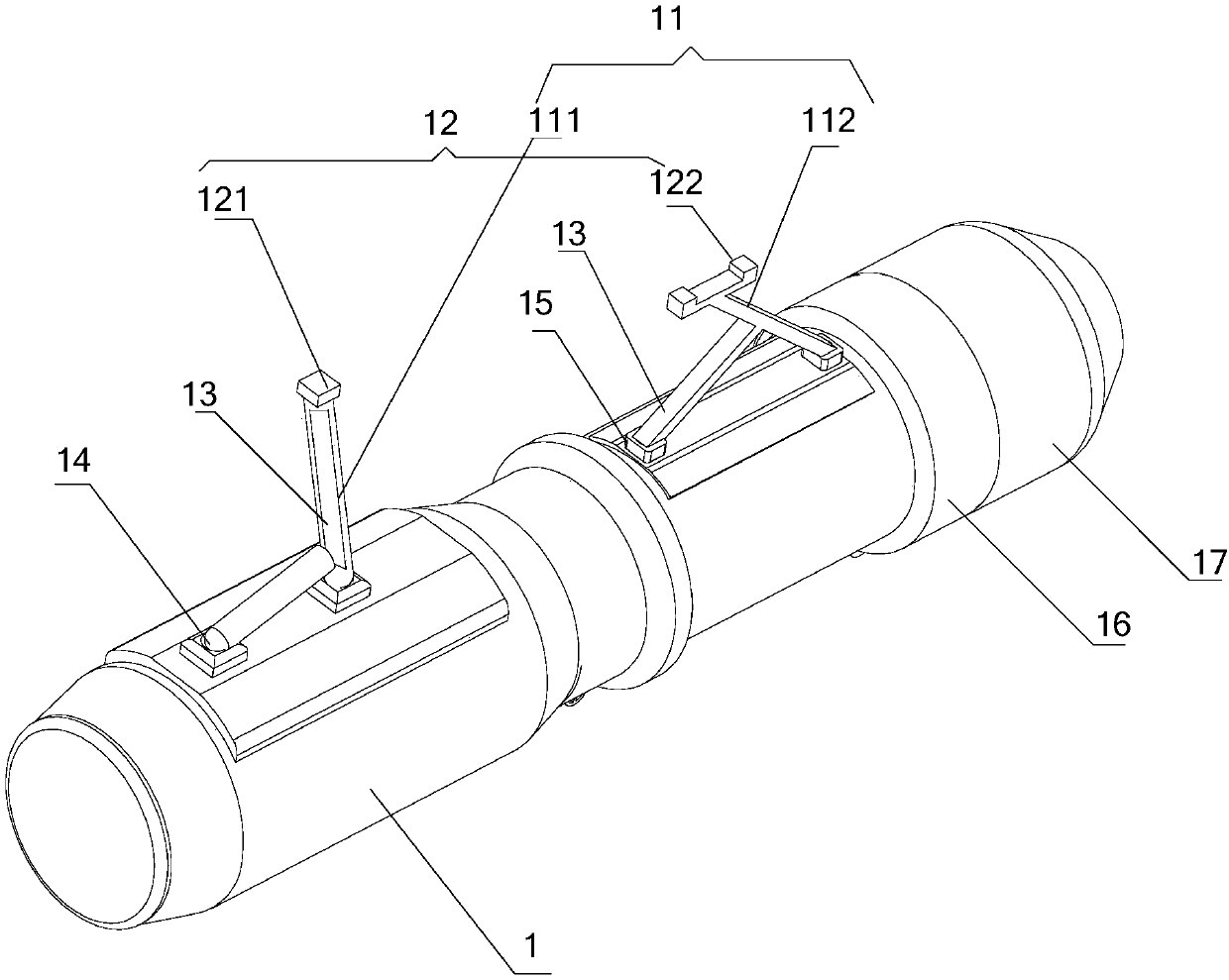

[0041] An embodiment of the present invention provides a pipeline robot detection device, such as figure 1 As shown, it includes a body 1, including: at least one set of rotatable brackets 11, which are installed on the body 1 and can rotate to a first preset angle; detection devices 12, which are installed on the rotatable brackets 11, are used to detect whether the pipeline Fault; the angle sensor 13 is arranged inside the rotatable support 11 and is used to detect the current rotation angle of the rotatable support 11 .

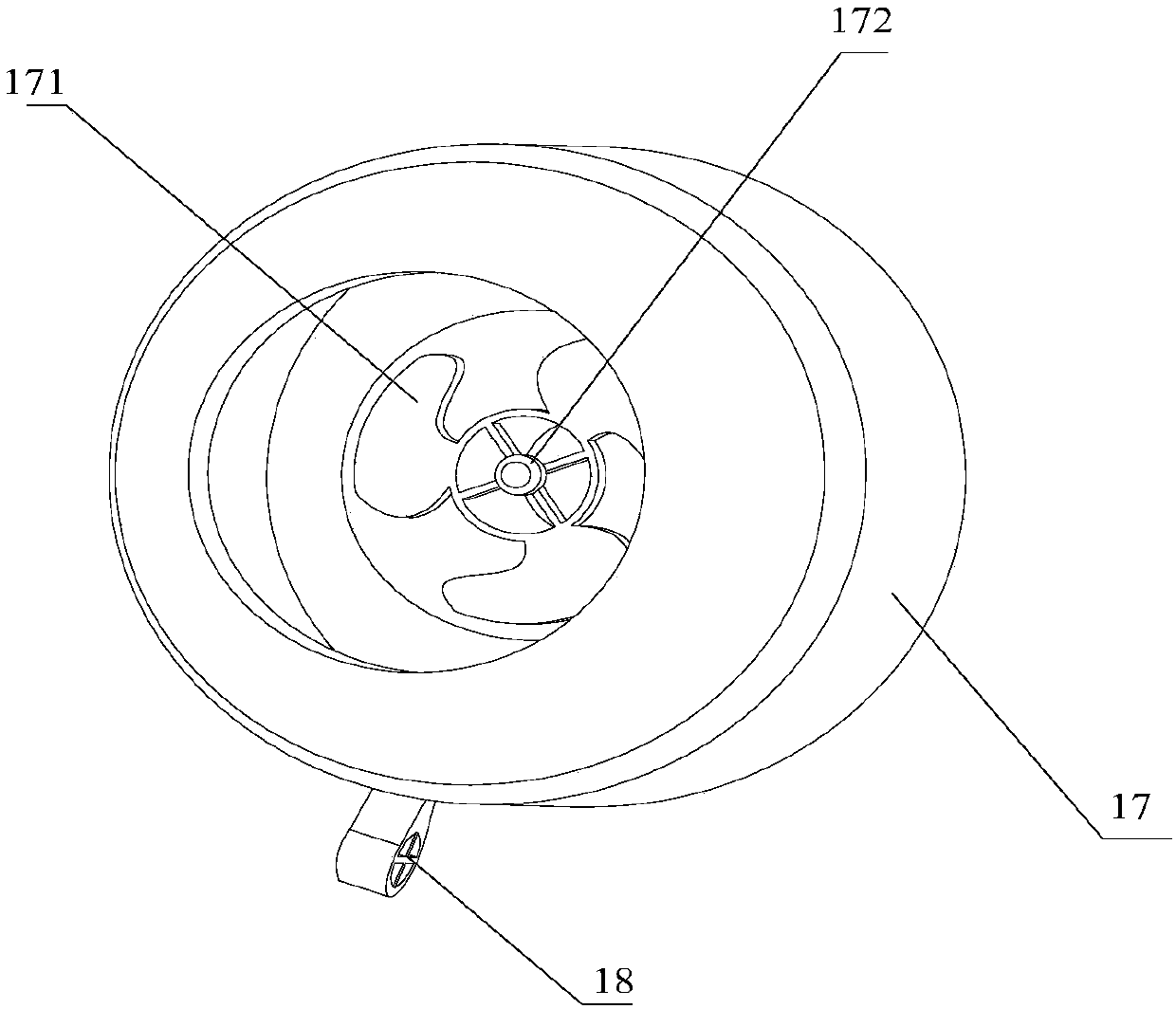

[0042] Specifically, such as figure 2 As shown, the rotatable bracket 11 includes a first variable-diameter bracket 111 and a second variable-diameter bracket 112, wherein the first variable-diameter bracket 111 is connected to the body 1 through a fixed hinge 14, and the first variable-diameter bracket 111 is located at the front of the body 1. The second reducing bracket 112 is connected with the body 1 through the hinge plate 15, the second reducing b...

Embodiment 2

[0055] The pipeline robot detection device provided by the embodiment of the present invention, the embodiment of the present invention provides a pipeline robot detection device, such as figure 1 and figure 2 As shown, it includes a body 1, including: at least one set of rotatable brackets 11, which are installed on the body 1 and can rotate to a first preset angle; detection devices 12, which are installed on the rotatable brackets 11, are used to detect whether the pipeline Fault; the angle sensor 13 is arranged inside the rotatable support 11 and is used to detect the current rotation angle of the rotatable support 11 . It also includes a control panel arranged outside the pipeline, on which a control circuit is arranged and connected to the detection device 12 and the angle sensor 13 respectively.

[0056] Specifically, the control circuit is connected to the angle sensor 13 through a cable signal transmission line provided inside the body 1 . The control circuit inclu...

Embodiment 3

[0059] An embodiment of the present invention provides a pipeline fault detection method, which is used in the pipeline robot detection device in Embodiment 1 and Embodiment 2, such as Figure 4 shown, including the following steps:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com