Preparation method and usage of core-core-hull ternary composite material Co3O4/PANI/MnO2

A composite material, hexadecyltrimethylammonium bromide technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problem of low conductivity and achieve the effect of good shape, easy industrial production, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

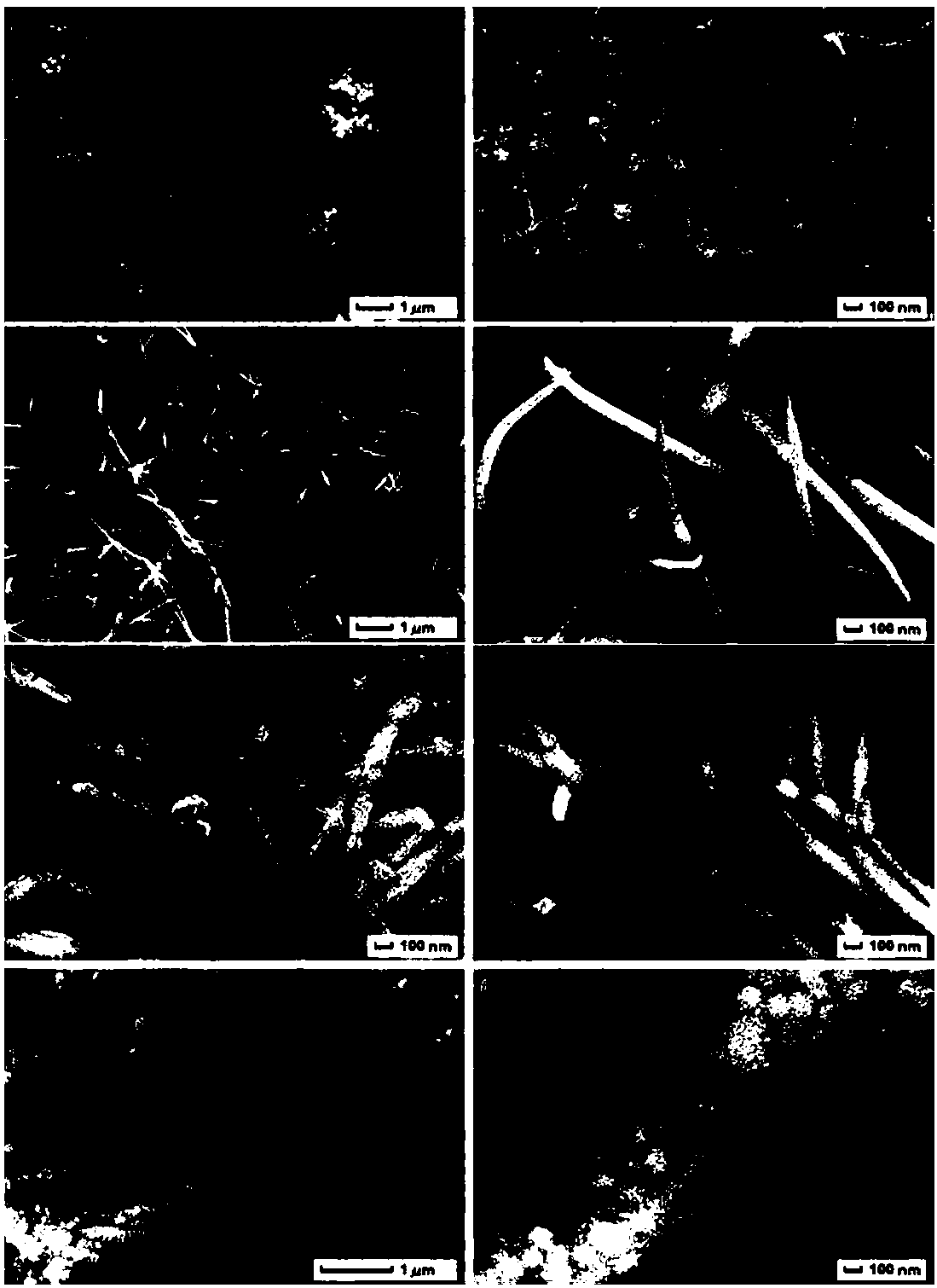

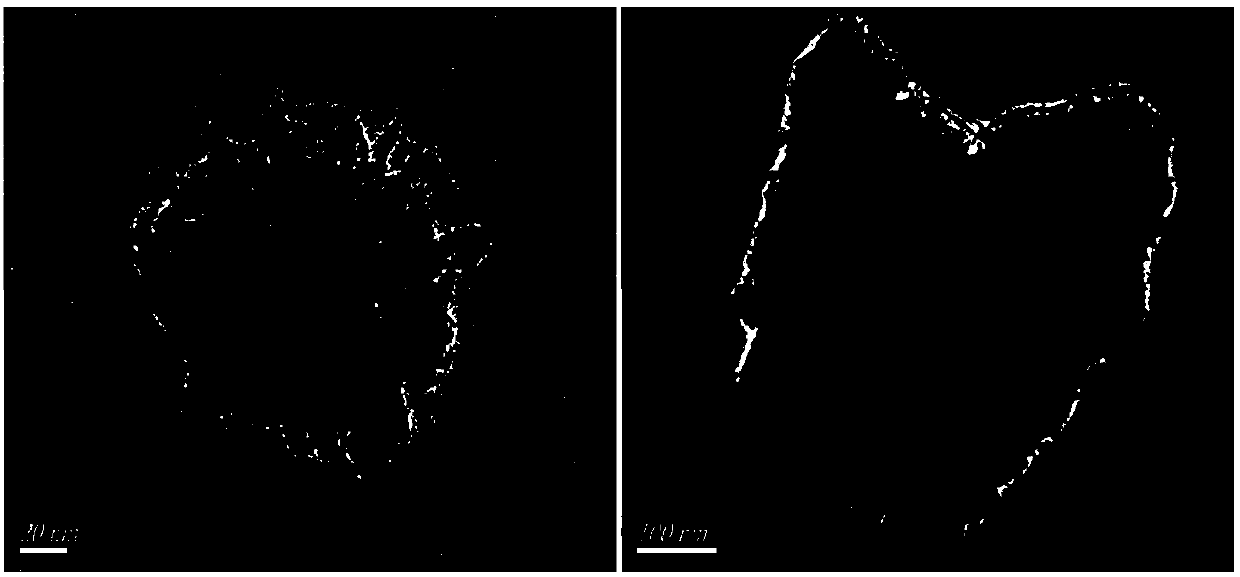

[0027] Example 1

[0028] Accurately weigh 0.31g cobalt nitrate hexahydrate, 0.085g ammonium fluoride, 0.3226g urea and 0.05g cetyltrimethylammonium bromide (CTAB), dissolve them in 30mL deionized water, prepare the precursor solution, and then pour Put it into a 50mL reactor;

[0029] Use a piece of foamed nickel (1cm×1cm) with 1mol·L in advance -1 Washed with hydrochloric acid, acetone and deionized water, then put it into the reactor and immerse it in the above solution. The reactor will react at 100℃ for 8h, and the foamed nickel substrate loaded with the product will be ultrasonically dispersed in deionized water and ethanol for 1 min. , Then clean it, put it in an oven at 60℃ to dry, put the sample in a muffle furnace at 300℃ for 3h to obtain Co on the foamed nickel 3 O 4 Nanowires;

[0030] Then, with the obtained long Co 3 O 4 The foamed nickel of the nanowire is the working electrode, the platinum electrode is the auxiliary electrode, and the saturated calomel electrode is ...

Example Embodiment

[0032] Example 2

[0033] Accurately weigh 0.31g cobalt nitrate hexahydrate, 0.085g ammonium fluoride, 0.3226g urea and 0.1g cetyltrimethylammonium bromide (CTAB) and dissolve them in 30mL deionized water to prepare a precursor solution; then pour Put it into a 50mL reactor;

[0034] Use a piece of foamed nickel (1cm×1cm) with 1mol·L in advance -1 Washed with hydrochloric acid, acetone and deionized water, then put it into the reactor and immerse it in the above solution. The reactor will react at 120℃ for 10h, and the foamed nickel substrate loaded with the product will be ultrasonically dispersed in deionized water and ethanol for 1min. , Then clean it, put it in an oven at 60℃ to dry, put the sample in a muffle furnace at 350℃ for 3h to obtain Co on the foamed nickel 3 O 4 Nanowires;

[0035] Then, with the obtained long Co 3 O 4 The foamed nickel of the nanowire is the working electrode, the platinum electrode is the auxiliary electrode, and the saturated calomel electrode is th...

Example Embodiment

[0039] Example 3

[0040] Accurately weigh 0.31g of cobalt nitrate hexahydrate, 0.085g of ammonium fluoride, 0.3226g of urea and 0.1g of cetyltrimethylammonium bromide (CTAB), dissolve them in 30mL of deionized water, prepare the precursor solution, and then pour Put it into a 50mL reactor;

[0041] Use a piece of foamed nickel (1cm×1cm) with 1mol·L in advance -1 Washed with hydrochloric acid, acetone and deionized water, then put into the reactor, immersed in the above solution, the reactor was reacted at 150℃ for 12h, and the foamed nickel substrate loaded with the product was ultrasonically dispersed in deionized water and ethanol for 1 min. , Then clean it, put it in an oven at 60°C to dry, place the sample in a muffle furnace at 500°C for 3h to obtain Co on the foamed nickel 3 O 4 Nanowires;

[0042] Then, with the obtained long Co 3 O 4 The foamed nickel of the nanowire is the working electrode, the platinum electrode is the auxiliary electrode, and the saturated calomel elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com