Automatic arranging system for single-row type lead-acid cell plate groups

A lead-acid battery, automatic arrangement technology, applied in the direction of lead-acid battery, lead-acid battery construction, sustainable manufacturing/processing, etc. The effect of ingenious, avoiding deviation and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0077] The embodiments are described below with reference to the drawings. The embodiments shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configuration shown in the embodiments below are not limited to the invention described in the claims. Necessary for the solution.

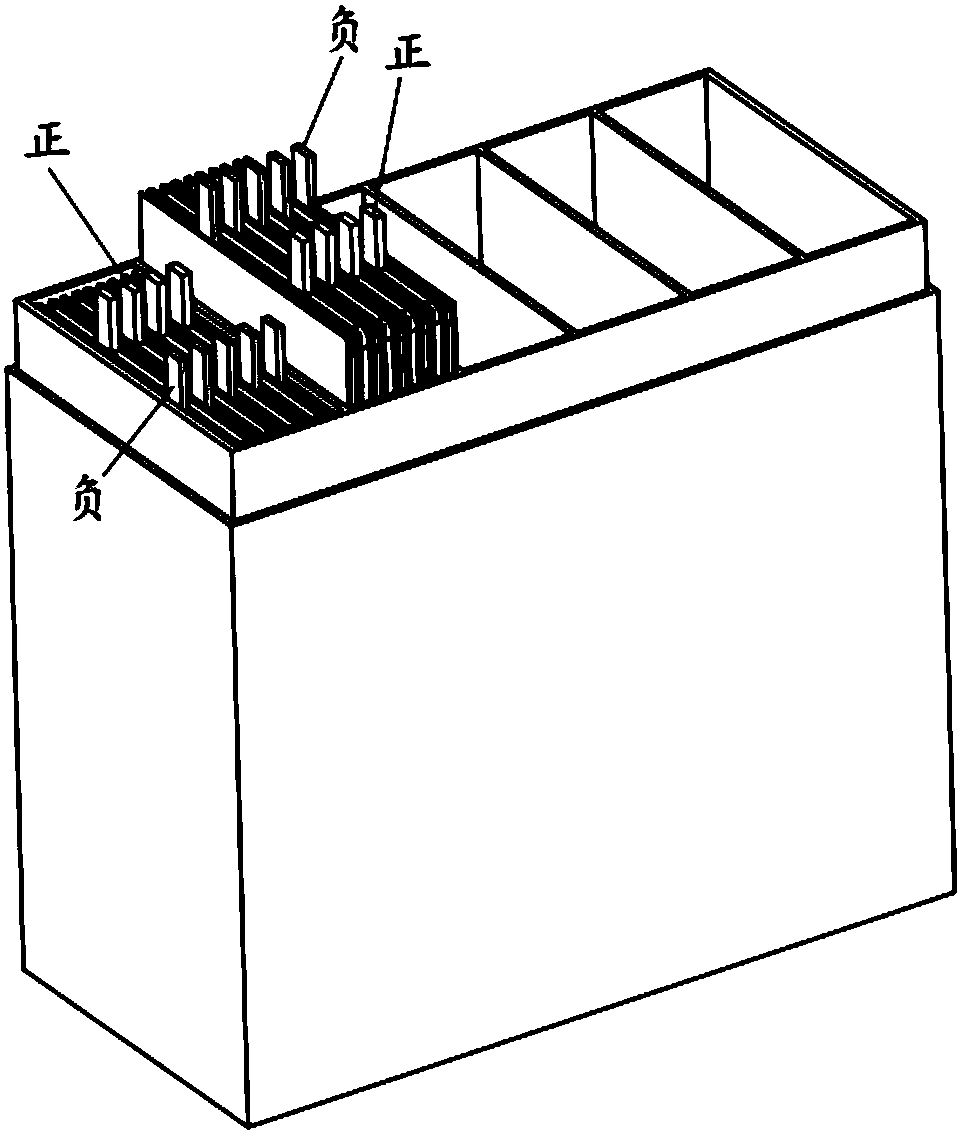

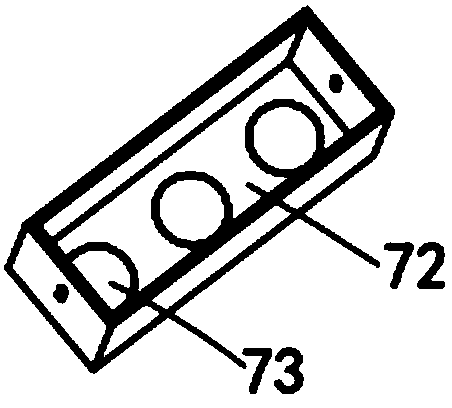

[0078] Such as figure 2 , image 3 , Figure 4 versus Figure 5 As shown, a single-row lead-acid battery pole group automatic arranging system includes a pole group 7. The pole group 7 includes a pole group 71, a fixing sleeve 72, and a plurality of magnetic counterweights 73. The pole group 71 Inserted into the fixing sleeve 72, the magnetic counterweights 73 are all arranged at the bottom of the fixing sleeve 72, including:

[0079] Rack 1, the rack 1 is divided into a first mounting portion 11 at the front end and a second mounting portion 12 at the rear end, the first mounting portion 11 is arranged in a straight line, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com