Transport unit

A technology of facilities and receiving equipment, which is applied in the direction of transportation and packaging, trolley cranes, load hanging components, etc., can solve the problem of increasing the self-weight of load receiving equipment, and achieve the effect of reducing self-weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

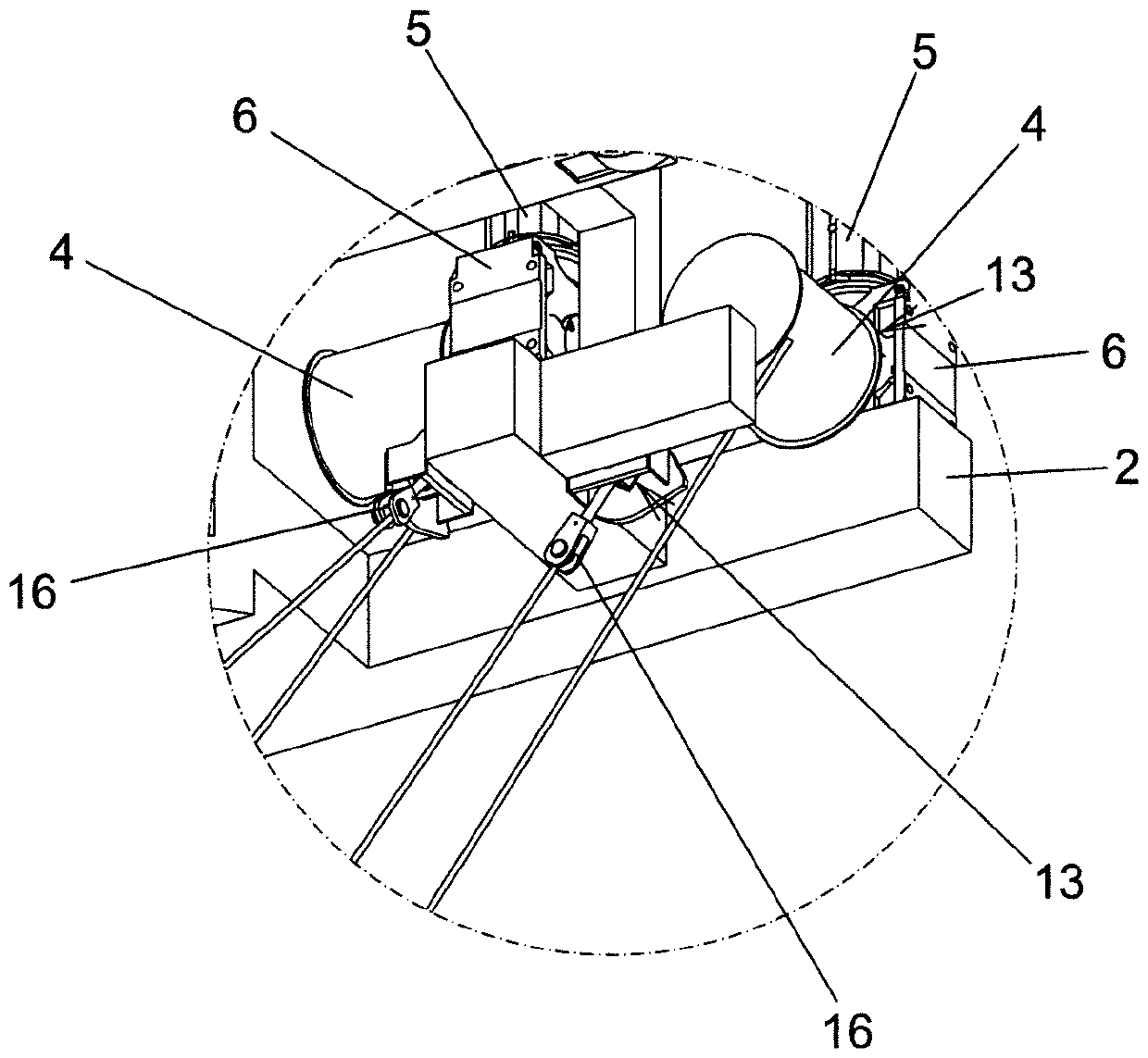

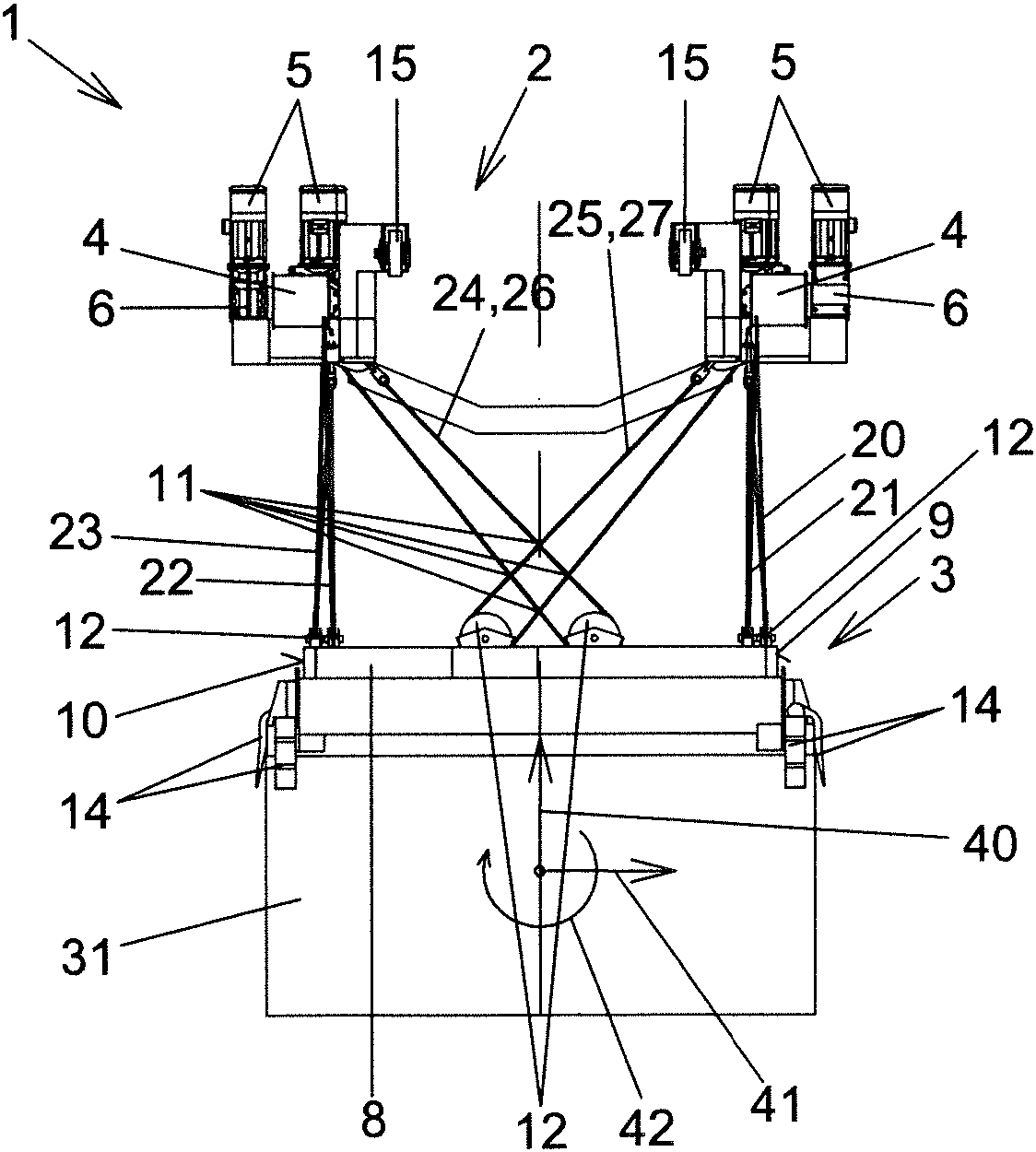

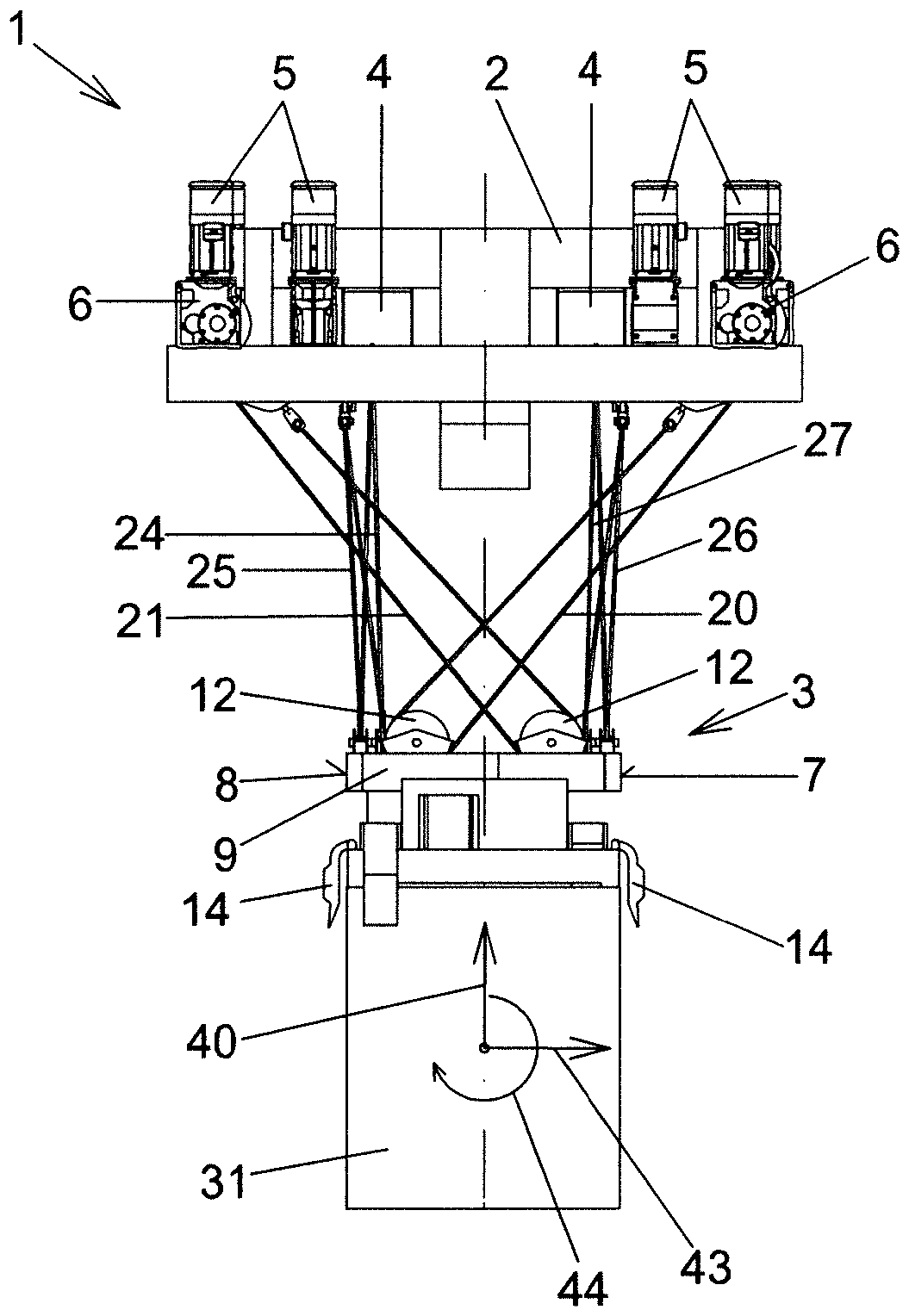

[0040] The transport facility 1 has a crane trolley 2 and a load receiving device 3 . The load receiving device 3 is used for securing containers 31 and has a number of known connection facilities 14 for this purpose. These connection facilities are also referred to as "Flippers". The load receiving device 3 is suspended from the trolley trolley 2 by means of eight lifting cables 20-27 and can be moved relative to the trolley trolley 2 by lengthening or shortening the free length of the individual lifting cables 20-27.

[0041] The hoisting ropes 20 - 27 can be wound individually or unwound on the rope drum 4 , which is mounted rotatably on the trolley 2 . The number of rope drums 4 also corresponds to the number of lifting ropes 20-27. All cable drums 4 can be driven individually or independently of each other at different or the same speed of rotation and / or with different or the same direction of rotation. Each rope drum 4 is driven by its own motor 5 in the present embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com