Automatic paint sprayer and method

An automatic paint spraying machine and automatic technology, applied in the directions of spraying device, liquid spraying equipment, electrostatic spraying device, etc., can solve the problems of high workshop space requirements, large equipment volume and high use cost, and achieve the improvement of painting efficiency, low equipment cost, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

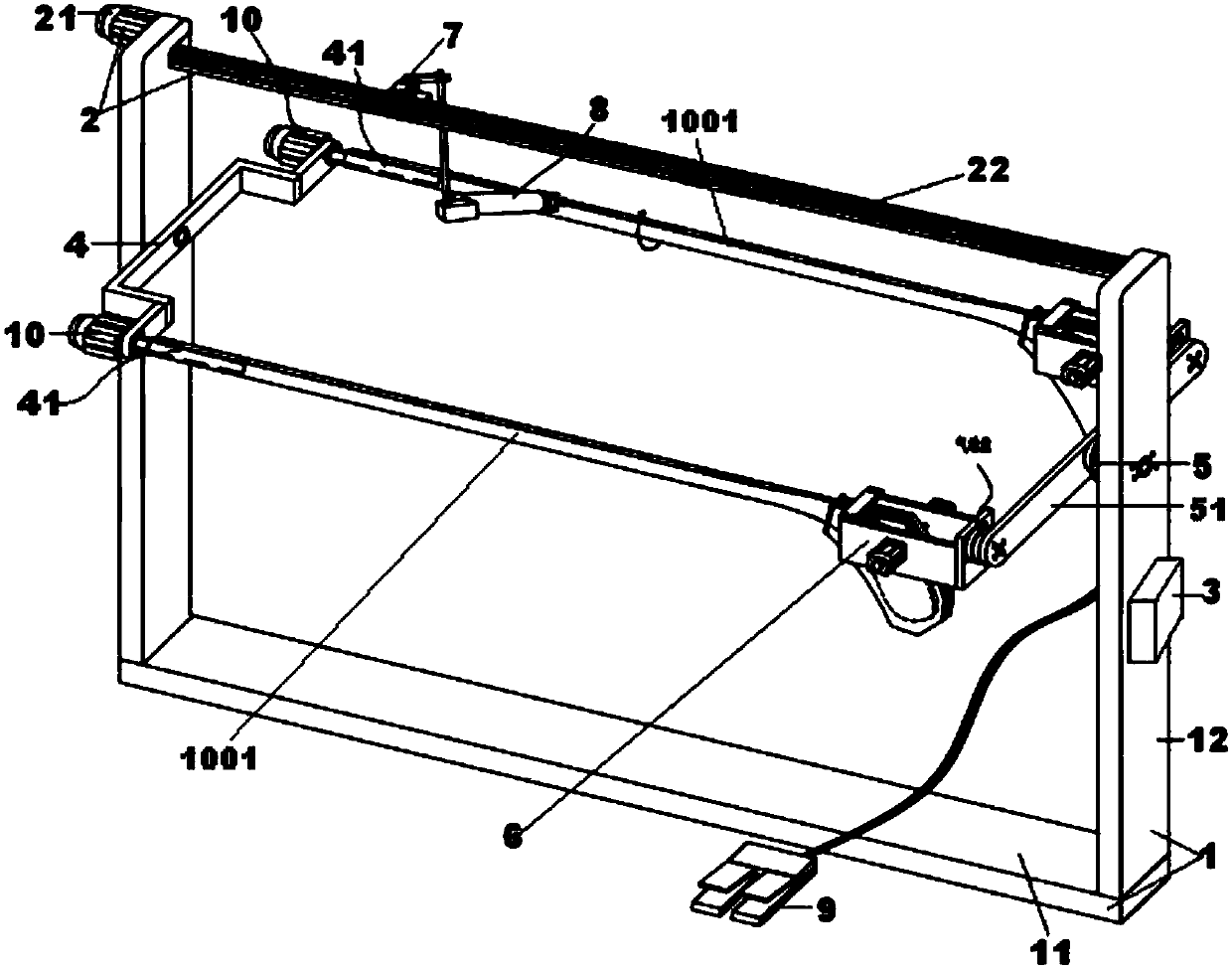

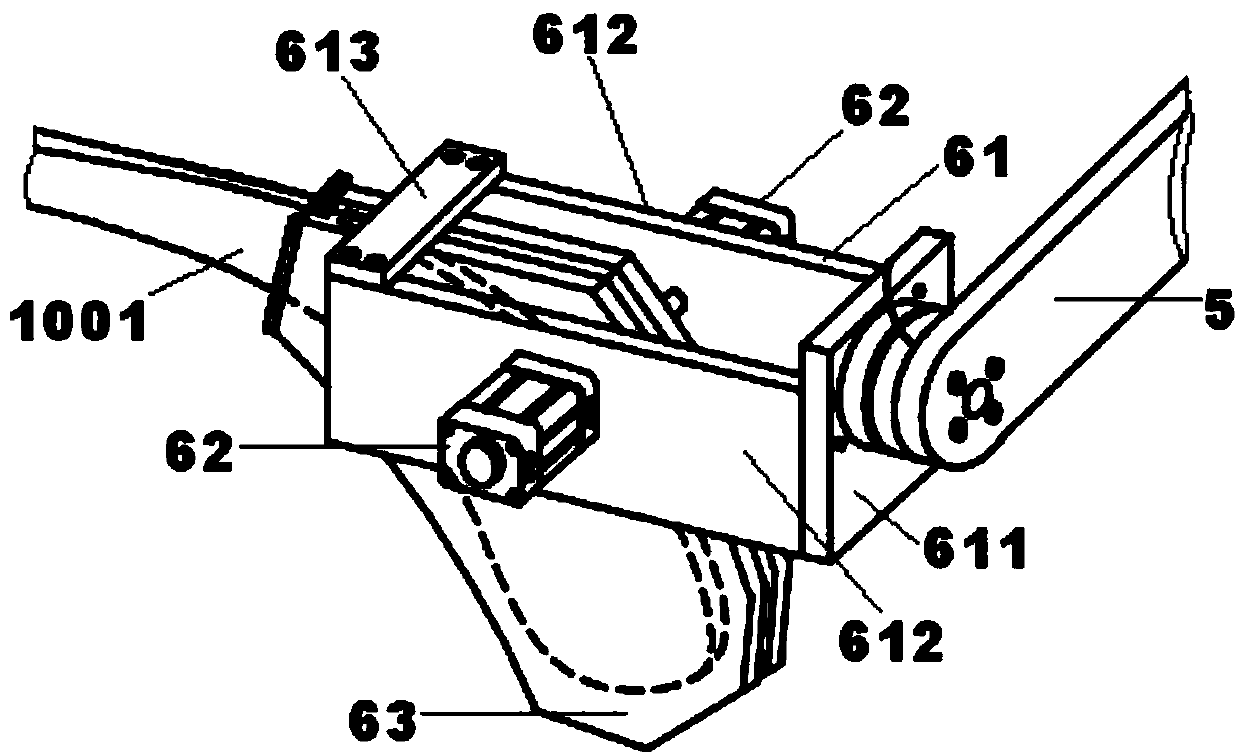

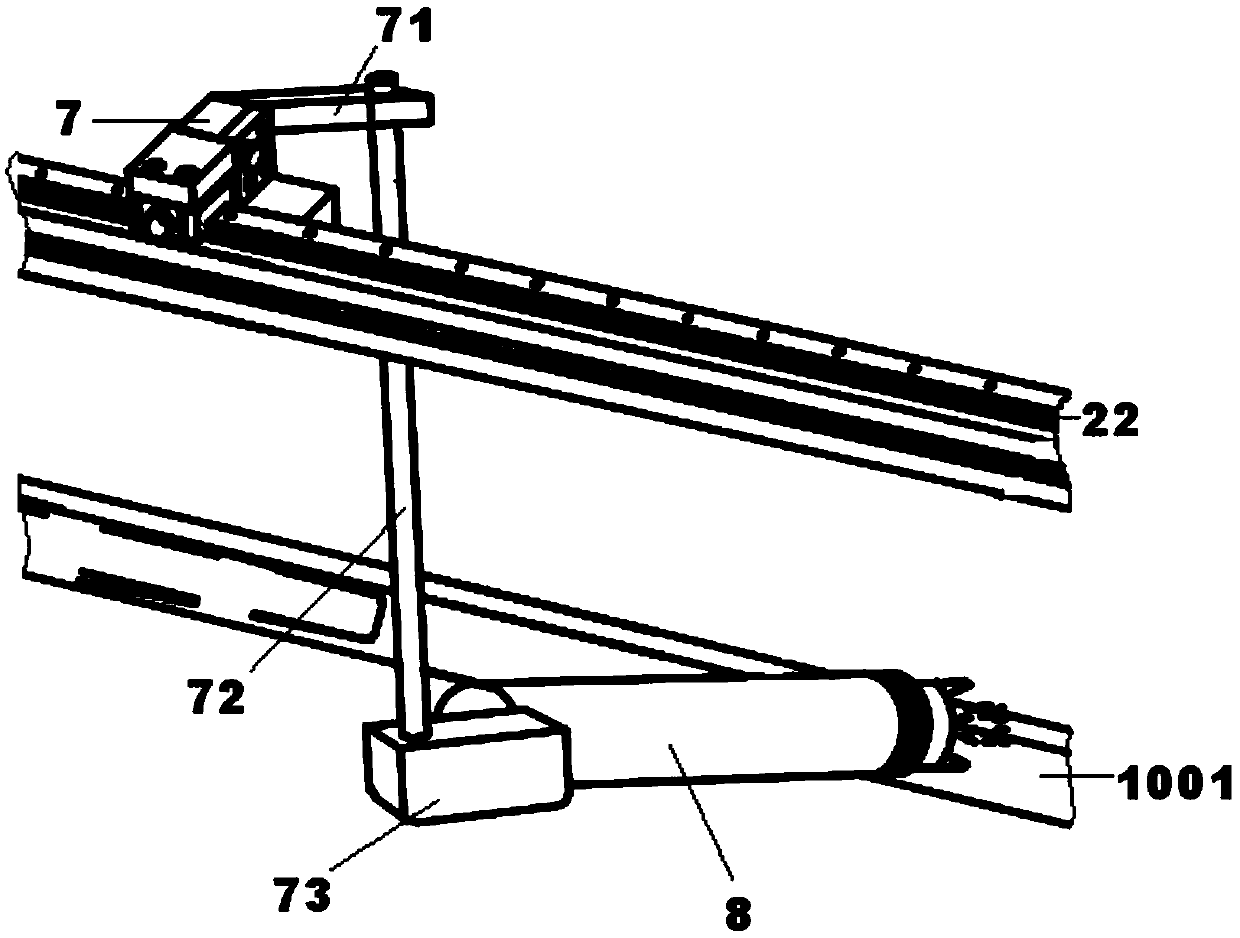

[0051] Such as figure 1 The illustrated embodiment is an automatic paint spraying machine, comprising a frame 1, a laterally extending guide device 2, a controller 3 and an alarm arranged on the frame, a support rod 4 arranged on the left side of the frame, and a The 180-degree rotating cylinder 5 on the right side of the bracket is arranged on the two striking plate fixtures 6 at both ends of the connecting rod 51 of the 180-degree rotating cylinder; each striking plate fixture is provided with a pressure sensor, and the guide device is provided with a fixed block 7, The fixed block is provided with an automatic electrostatic paint spray gun 8 that can move up and down; the support rod is provided with two club end positioning structures 41 corresponding to the two striking plate fixtures respectively; the pneumatic foot switch 9 is electrical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com