Lithium battery pole piece one-dividing-into-two closed-loop rectifying and slitting method and system

A technology that divides into two and lithium batteries is applied in other manufacturing equipment/tools, metal processing machinery parts, measuring/indicating equipment, etc., which can solve the problems of poor product consistency, difference, and low position accuracy, and achieve convenient identification, The effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

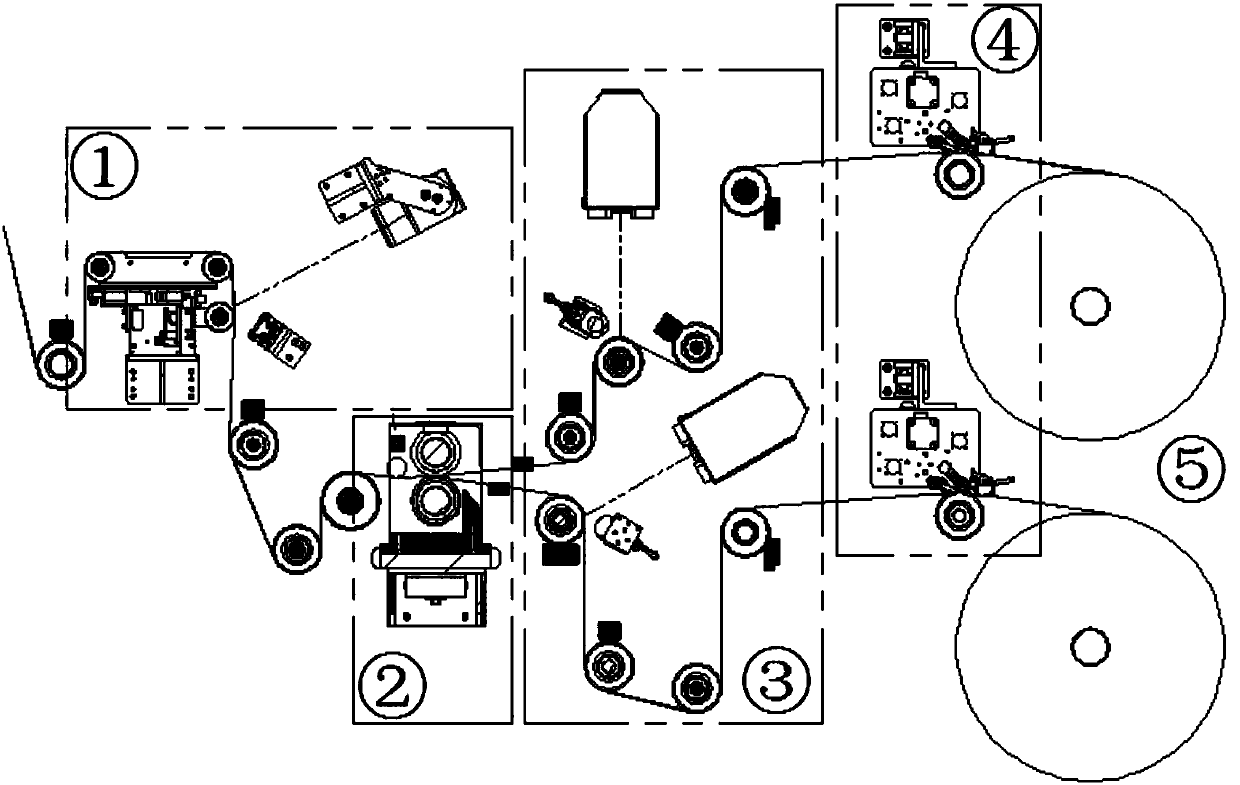

[0027] see Figures 1 to 5 , the lithium battery pole piece provided in this embodiment is divided into two closed-loop deflection correction and cutting methods, including the following steps:

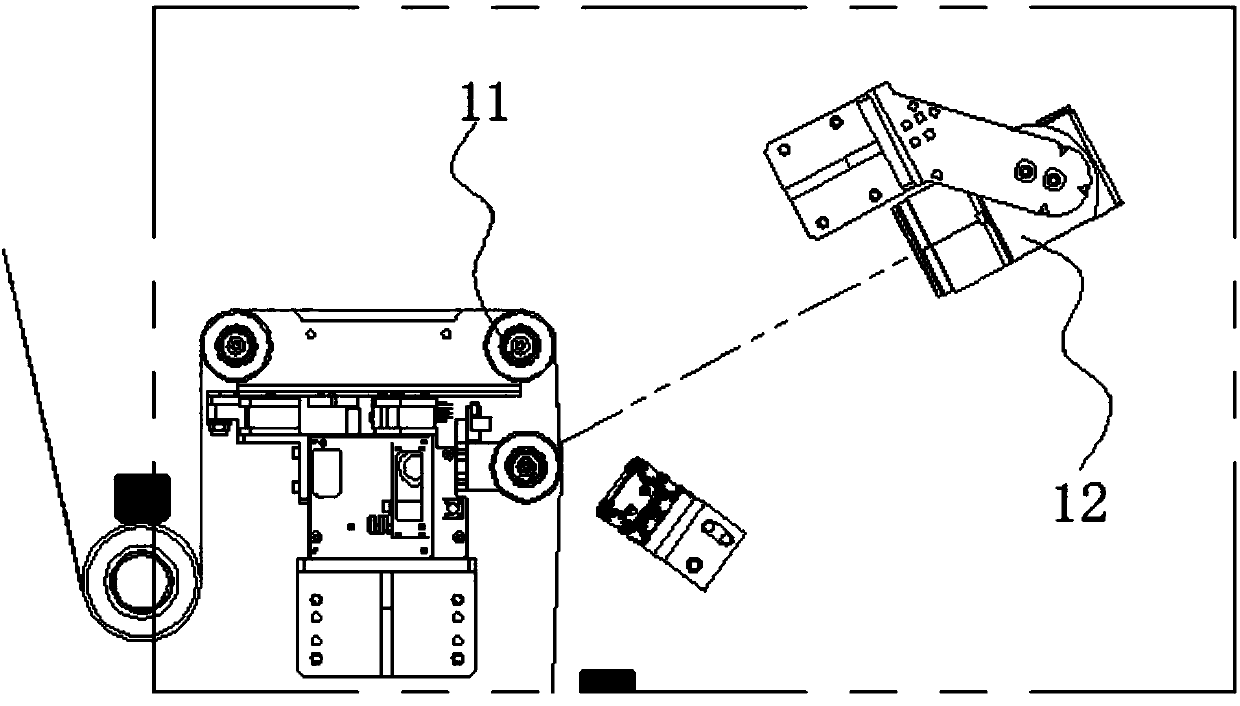

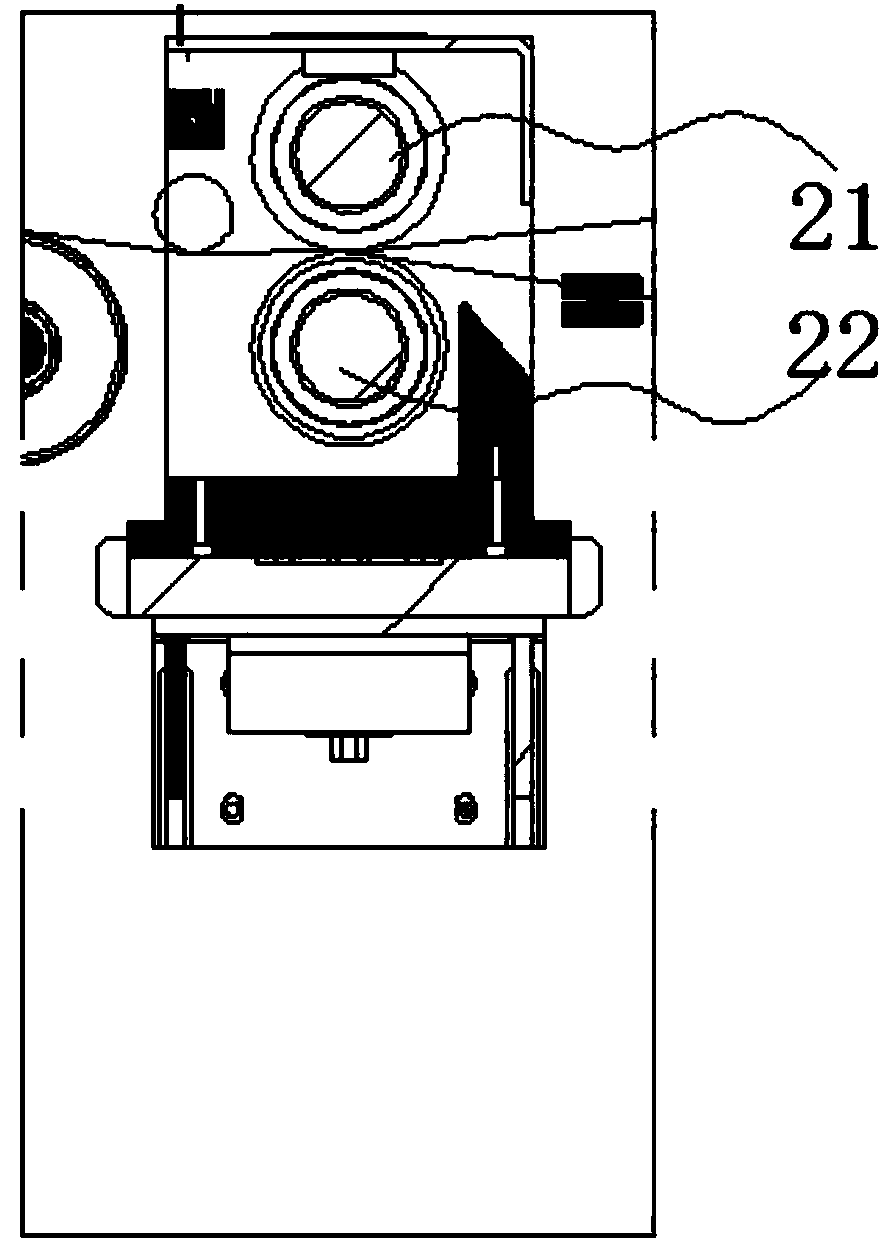

[0028]1) Set deviation correction system 1, cutting system 2, measurement system 3, labeling system 4, winding system 5 and communication linkage system to form a lithium battery pole piece 6 divided into two closed-loop deviation correction and cutting systems; the deviation correction system 1. Slitting system 2, measuring system 3, labeling system 4, and winding system 5 are set up in sequence according to the assembly line, and the communication linkage system is associated and coordinated with the deviation correction system 1, slitting system 2, measuring system 3, and labeling system 4. The communication and linkage between the winding systems 5 form a closed-loop operation. The deviation correction system 1 includes a deviation correction conveying roller set 11, a deviation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com