Cement floor trowelling machine for building

A technology for troweling machine and construction, applied in the direction of construction and building structure, etc., can solve the problems of single function, low troweling efficiency, simple structure of troweling machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

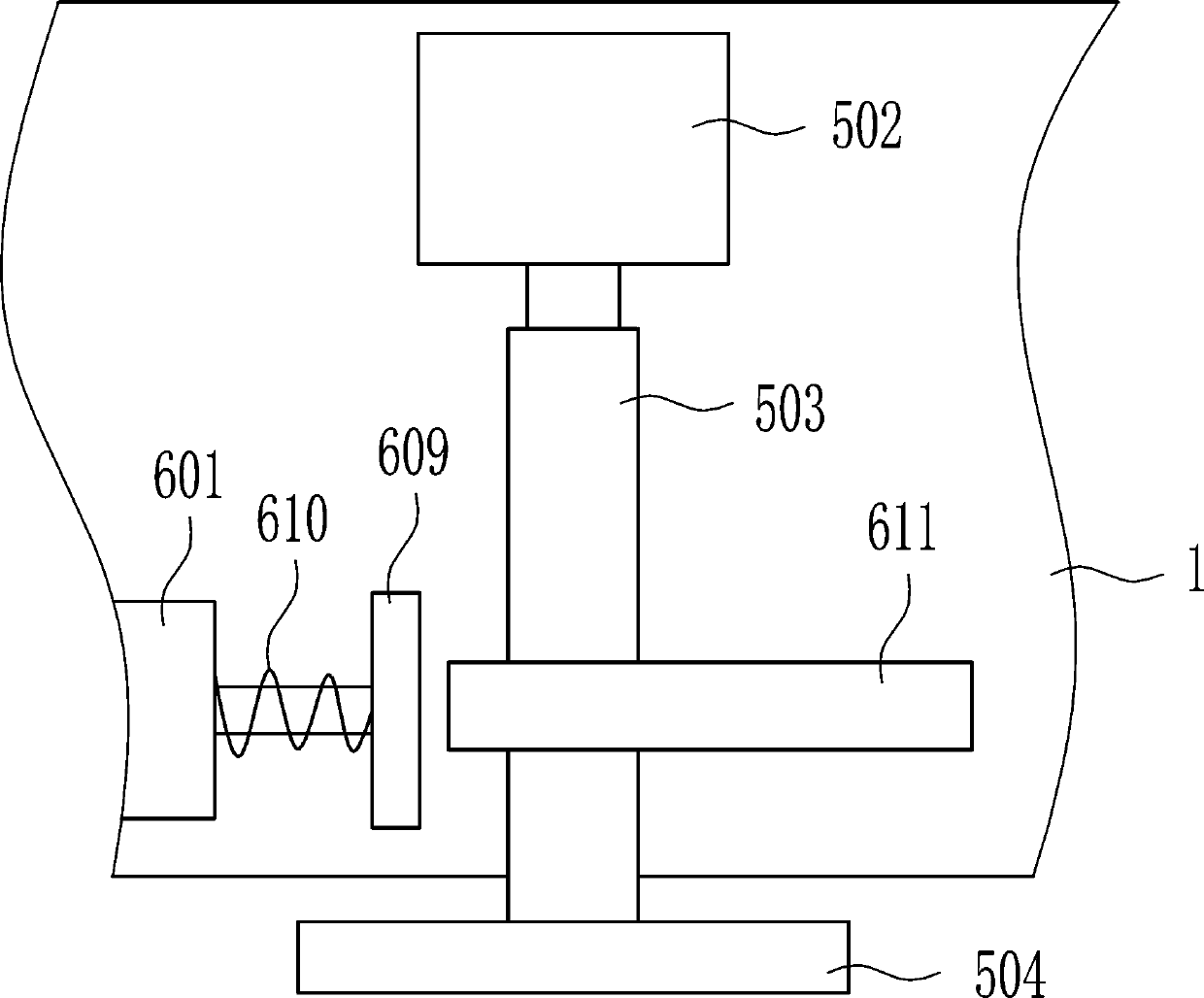

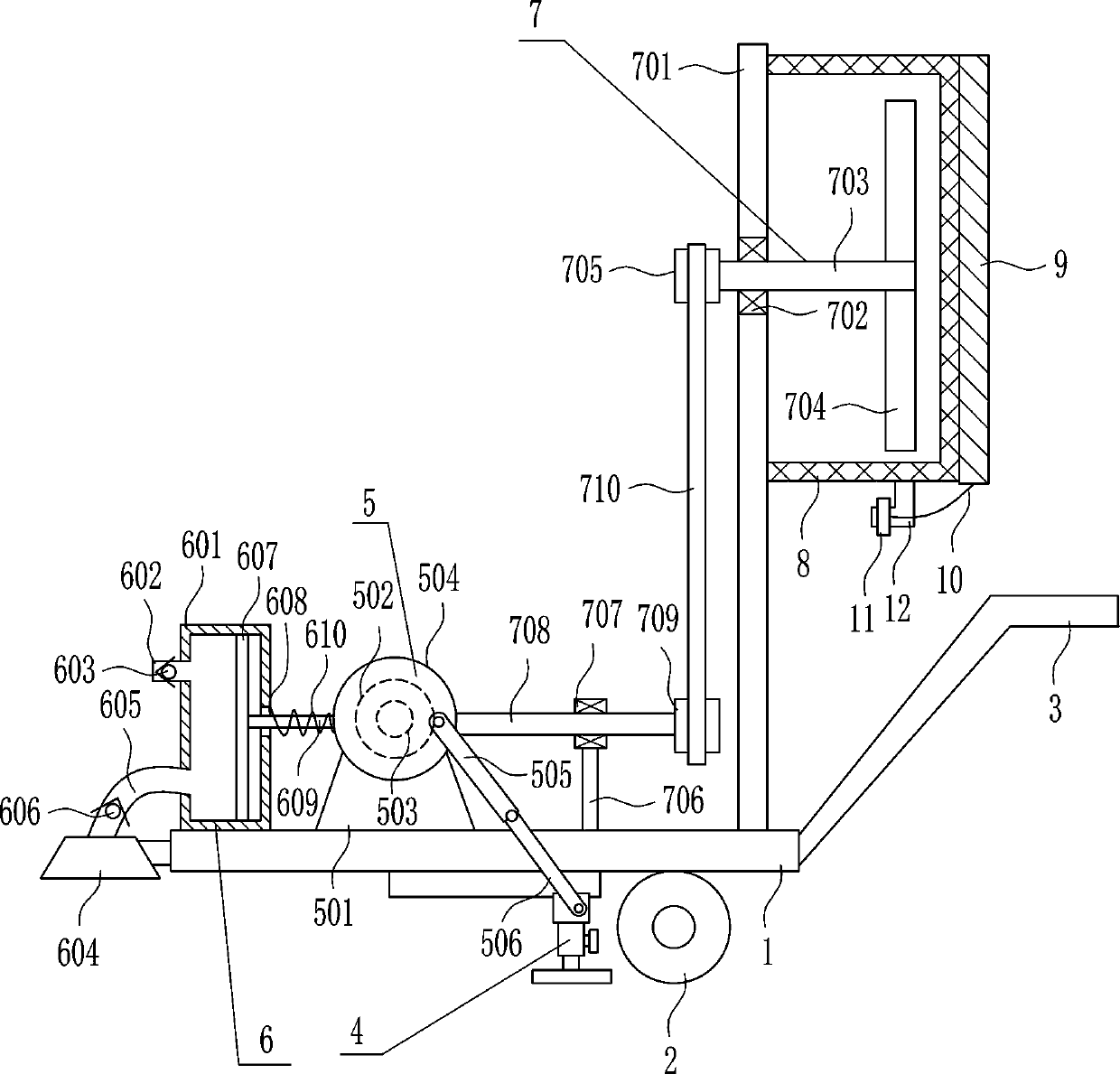

[0033] A kind of cement floor troweling machine for construction, such as Figure 1-7 As shown, it includes a horizontal plate 1, a wheel 2, a handle 3, a smoothing device 4 and a driving device 5, wheels 2 are arranged on the front and rear sides of the right side of the bottom of the horizontal plate 1, and a handle is connected to the right side of the horizontal plate 1. 3. A smoothing device 4 is provided in the middle of the bottom of the horizontal plate 1, and a driving device 5 is provided in the middle of the top of the horizontal plate 1.

Embodiment 2

[0035] A kind of cement floor troweling machine for construction, such as Figure 1-7 As shown, it includes a horizontal plate 1, a wheel 2, a handle 3, a smoothing device 4 and a driving device 5, wheels 2 are arranged on the front and rear sides of the right side of the bottom of the horizontal plate 1, and a handle is connected to the right side of the horizontal plate 1. 3. A smoothing device 4 is provided in the middle of the bottom of the horizontal plate 1, and a driving device 5 is provided in the middle of the top of the horizontal plate 1.

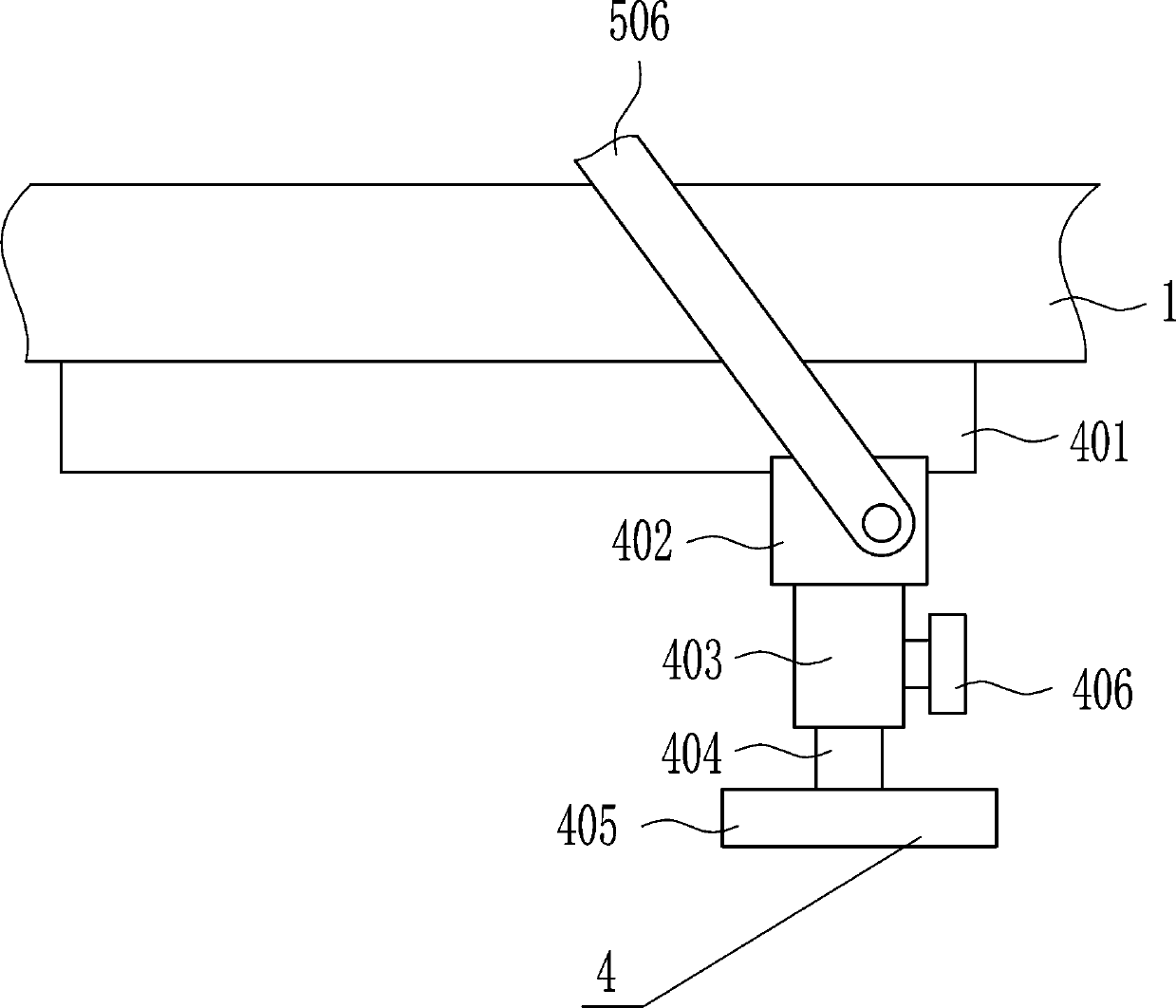

[0036] Troweling device 4 comprises slide rail 401, slide block 402, sleeve pipe 403, vertical rod 404, spatula 405 and fastening bolt 406, and the top of slide rail 401 is connected with the bottom of horizontal plate 1 in the middle, and slide rail 401 is provided with There is a slide block 402 slidingly matched with it, the bottom of the slide block 402 is connected with a sleeve 403, the sleeve 403 is provided with a vertica...

Embodiment 3

[0038] A kind of cement floor troweling machine for construction, such as Figure 1-7 As shown, it includes a horizontal plate 1, a wheel 2, a handle 3, a smoothing device 4 and a driving device 5, wheels 2 are arranged on the front and rear sides of the right side of the bottom of the horizontal plate 1, and a handle is connected to the right side of the horizontal plate 1. 3. A smoothing device 4 is provided in the middle of the bottom of the horizontal plate 1, and a driving device 5 is provided in the middle of the top of the horizontal plate 1.

[0039] Troweling device 4 comprises slide rail 401, slide block 402, sleeve pipe 403, vertical rod 404, spatula 405 and fastening bolt 406, and the top of slide rail 401 is connected with the bottom of horizontal plate 1 in the middle, and slide rail 401 is provided with There is a slide block 402 slidingly matched with it, the bottom of the slide block 402 is connected with a sleeve 403, the sleeve 403 is provided with a vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com