Transformer fault analysis system based on acoustic shock detection

A transformer failure and analysis system technology, applied in the direction of measuring electrical variables, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of incomplete reflection of transformer status and unreasonable evaluation methods of status monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

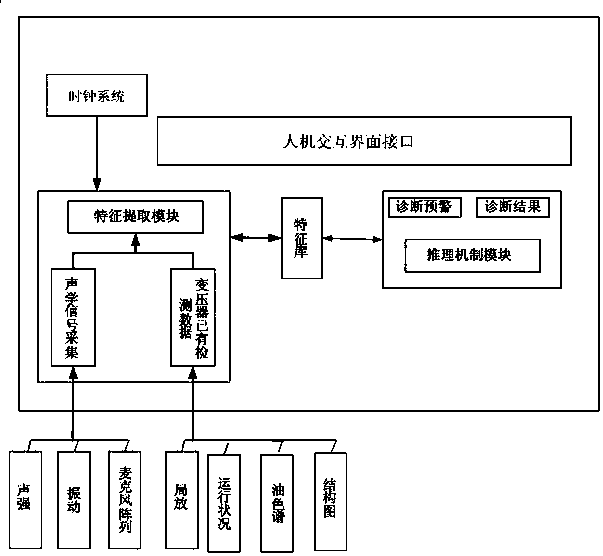

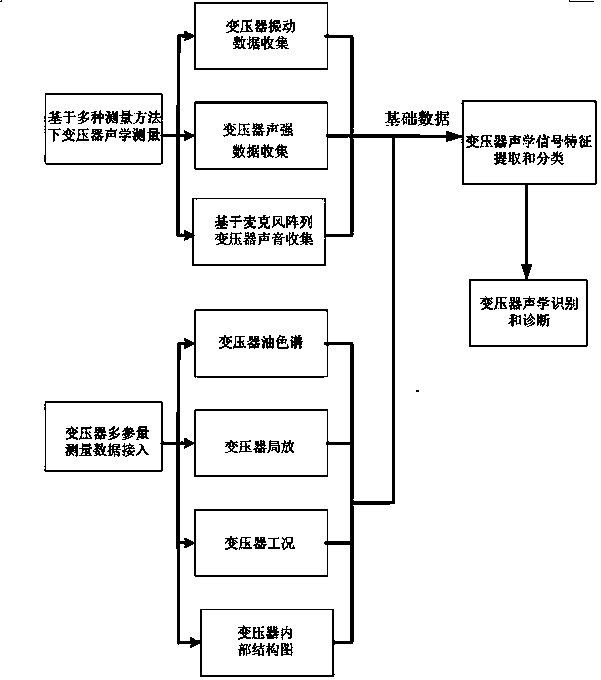

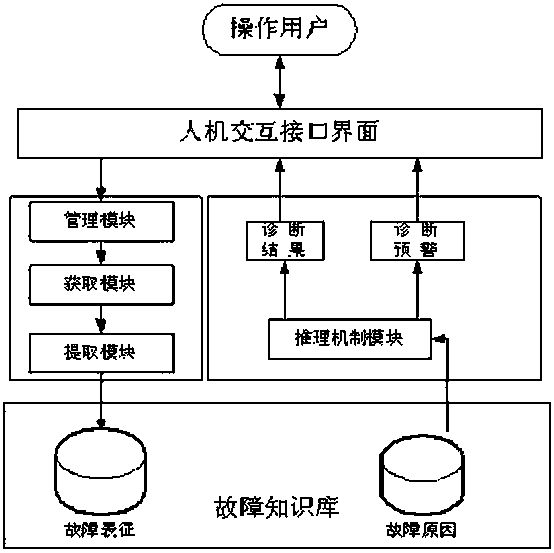

[0035] Such as Figure 1 to Figure 9As shown, the transformer fault analysis system based on acoustic vibration detection includes an interconnected data acquisition system and data analysis system. The data acquisition system includes an acoustic data acquisition module and a transformer parameter acquisition module. The acoustic data acquisition module includes a sound intensity sensor and a vibration sensor. and the sound sensor, the data analysis system includes a clock system and a signal feature extraction and classification module and a signal identification fault diagnosis module respectively connected with the clock system; the signal feature extraction and classification module includes a feature extraction module and a feature database, and the feature extraction module is connected to the data acquisition system, The signal recognition fault diagnosis module runs on the microcomputer system.

[0036] Vibration sensors include acceleration vibration sensors and lase...

Embodiment 2

[0072] Transformer fault analysis system based on acoustic vibration detection, including interconnected data acquisition system and data analysis system, data acquisition system includes acoustic data acquisition module and transformer parameter acquisition module, acoustic data acquisition module includes sound intensity sensor, vibration sensor and sound sensor , the data analysis system includes a clock system and a signal feature extraction and classification module and a signal recognition fault diagnosis module respectively connected to the clock system; the signal feature extraction and classification module includes a feature extraction module and a feature database, and the feature extraction module is connected to the data acquisition system to identify faults in the signal The diagnostic module runs on the microcomputer system. Vibration sensors include acceleration vibration sensors and laser vibrometers. The sound sensor includes a microphone array connected to a...

Embodiment 3

[0075] Transformer fault analysis system based on acoustic vibration detection, including interconnected data acquisition system and data analysis system, data acquisition system includes acoustic data acquisition module and transformer parameter acquisition module, acoustic data acquisition module includes sound intensity sensor, vibration sensor and sound sensor , the data analysis system includes a clock system and a signal feature extraction and classification module and a signal recognition fault diagnosis module respectively connected to the clock system; the signal feature extraction and classification module includes a feature extraction module and a feature database, and the feature extraction module is connected to the data acquisition system to identify faults in the signal The diagnostic module runs on the microcomputer system. Vibration sensors include acceleration vibration sensors and laser vibrometers. The sound sensor includes a microphone array connected to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com