Miniature circuit breaker shell automatic robot feeding system

A technology of small circuit breakers and robots, applied in the field of feeding systems, can solve problems such as low production efficiency, unstable product performance, and increase the labor intensity of operators, so as to avoid cost loss, ensure consistency, and improve product finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

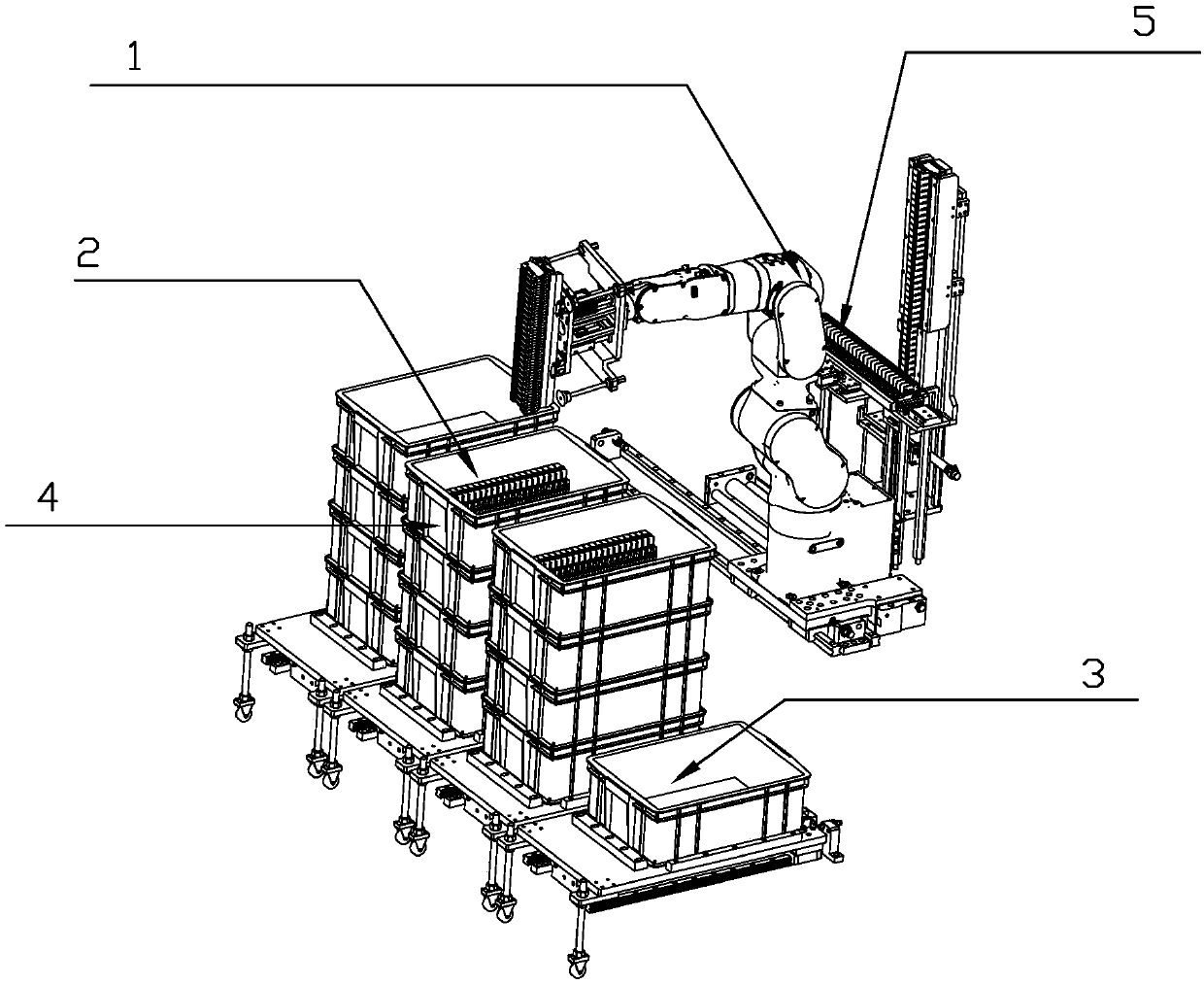

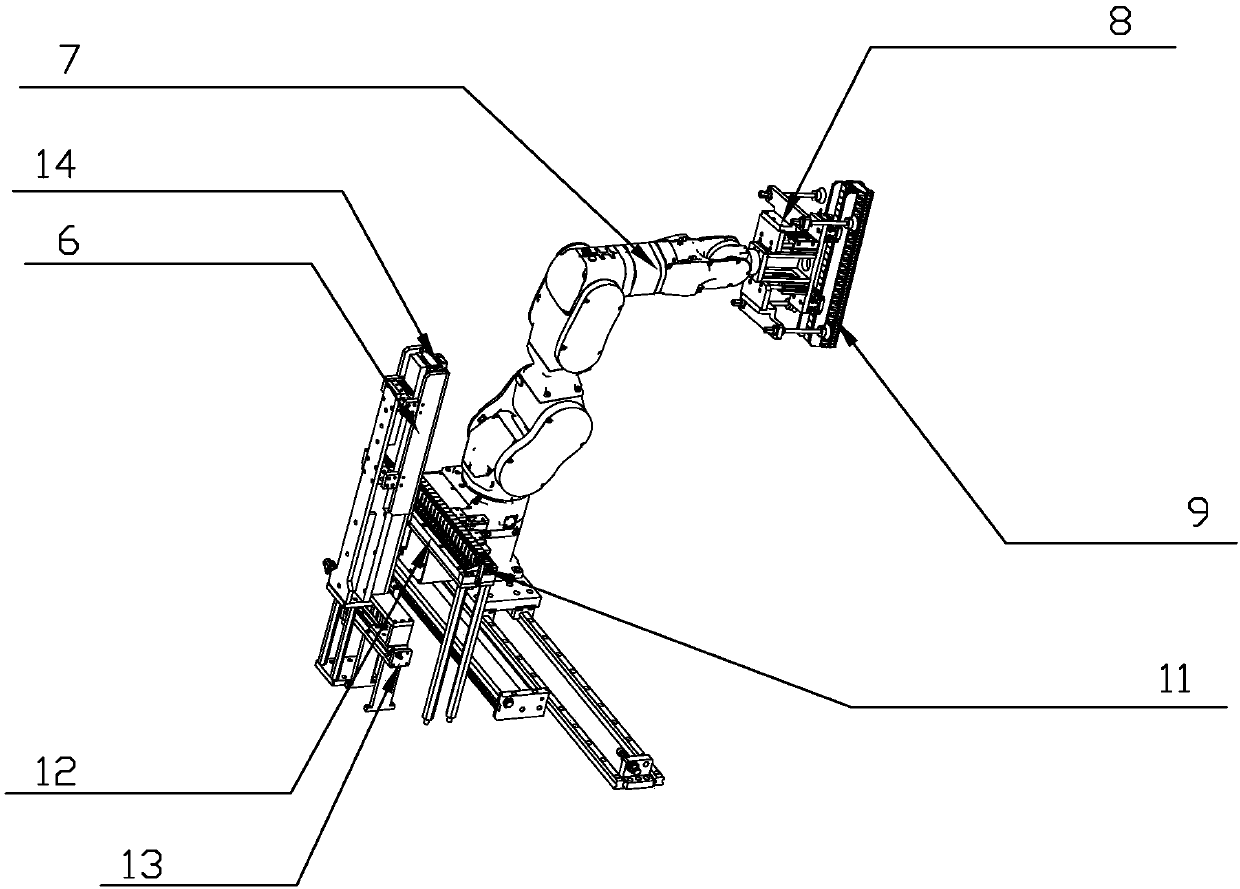

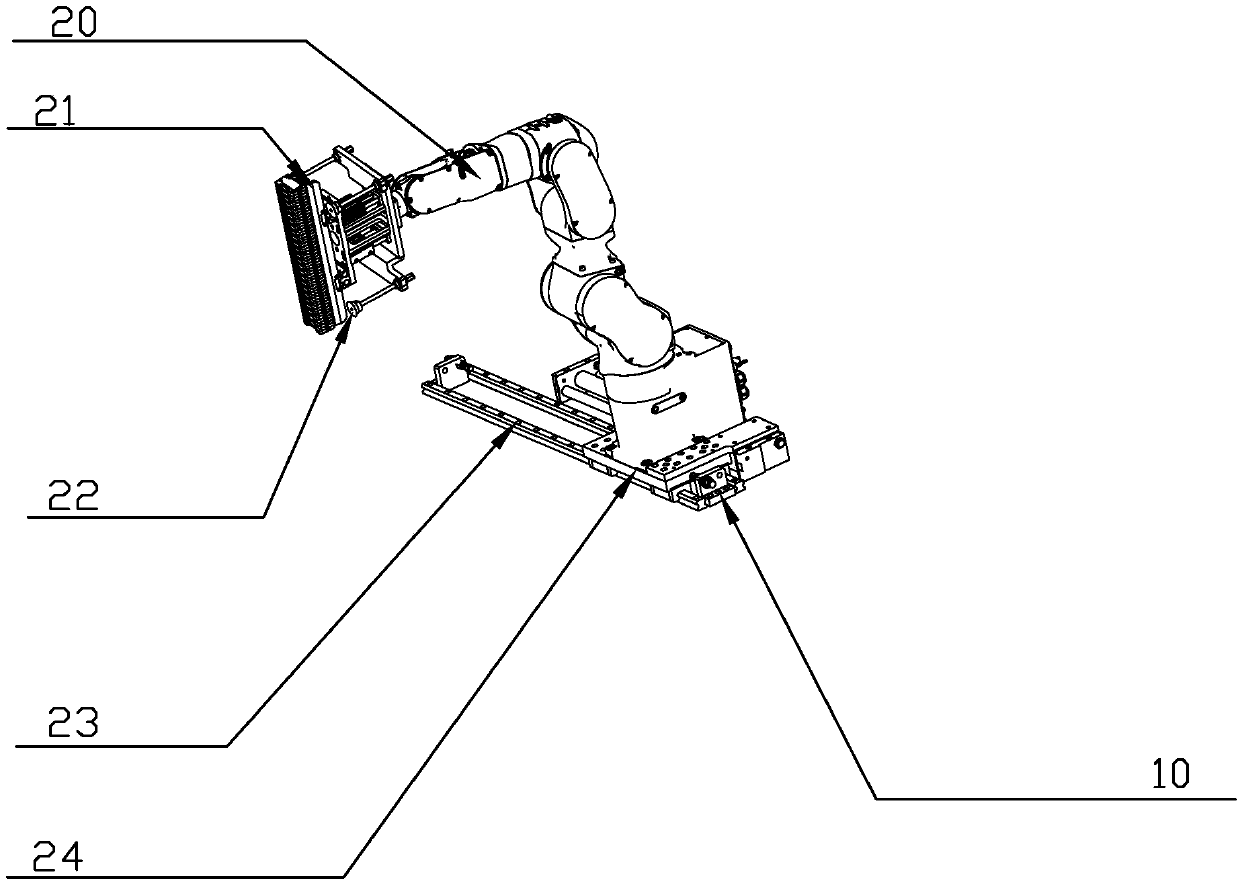

[0020] Such as Figures 1 to 3 The shown automatic robot feeding system for the miniature circuit breaker housing includes a material storage area 2 for storing materials, a material discharging device 4 for placing material boxes, and an empty box recycling area 3 for storing empty material boxes. The automatic robot feeding system 1 for the small circuit breaker shell includes an automatic mechanical action mechanism 7, a material regularization mechanism 5, and a conveying mechanism 6. The automatic mechanical action mechanism 1 includes a connection module 8 and a displacement module 10 for displacing the connection module. The connection module 8 includes a mechanical action connection end 9, which can be movably connected with the material and the material box, the material regularization mechanism 5 includes a material shaping unit 5, and the material shaping unit 5 includes a shaping clamping material end and a shaping detection end 11 for detecting the direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com