Auxiliary device for cleaning milk replacer tank

An auxiliary device and milk replacer technology, applied in the field of feed troughs, can solve the problems of splashing wet workers, troublesome cleaning of splashed water, easy splashing of impacting water, etc., and achieve the effect of saving manpower and increasing the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to explain the technical characteristics of the solution more clearly, the following describes the solution through specific implementations.

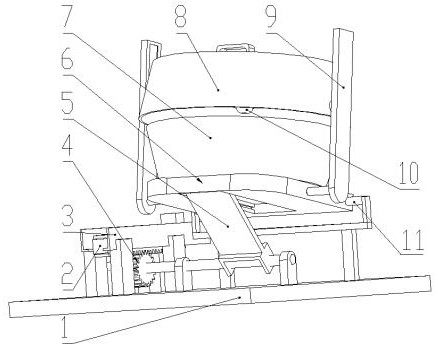

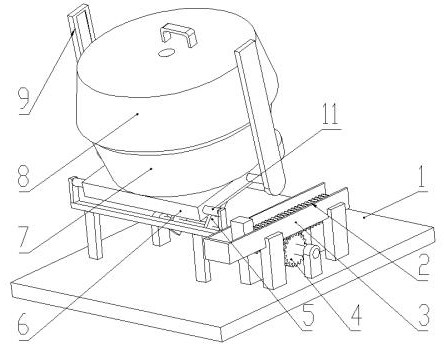

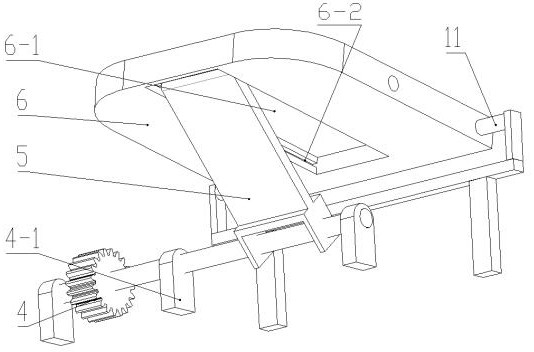

[0027] Such as figure 1 , figure 2 with image 3 As shown, the present invention adopts the following technical solutions: an auxiliary device for cleaning the milk replacer tank, mainly includes a turning mechanism, the turning mechanism includes a tooth plate 2 with an array of teeth on the bottom surface 2, an upper end surface opening and a bottom surface provided with elongated through holes The sliding groove plate 3, the gear 4 meshing with the array teeth of the tooth plate 2, the rotating shaft fixedly connected to the center of the gear 4, the rotating plate 5 fixedly connected with the rotating shaft, and the bottom surface is provided with a first sliding groove 6-1 and a second sliding groove 6-2 and the upper end surface is fixedly provided with the fixed plate 6 of the trough, the tooth plate 2 is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com