Transmission shaft end face forked end tooth key pulling tool

A drive shaft and end face technology, applied in the field of mechanical parts processing, can solve problems such as restricting enterprise development, rising processing costs, complex positioning structures, etc., and achieving the effects of reducing labor intensity, low cost, and reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

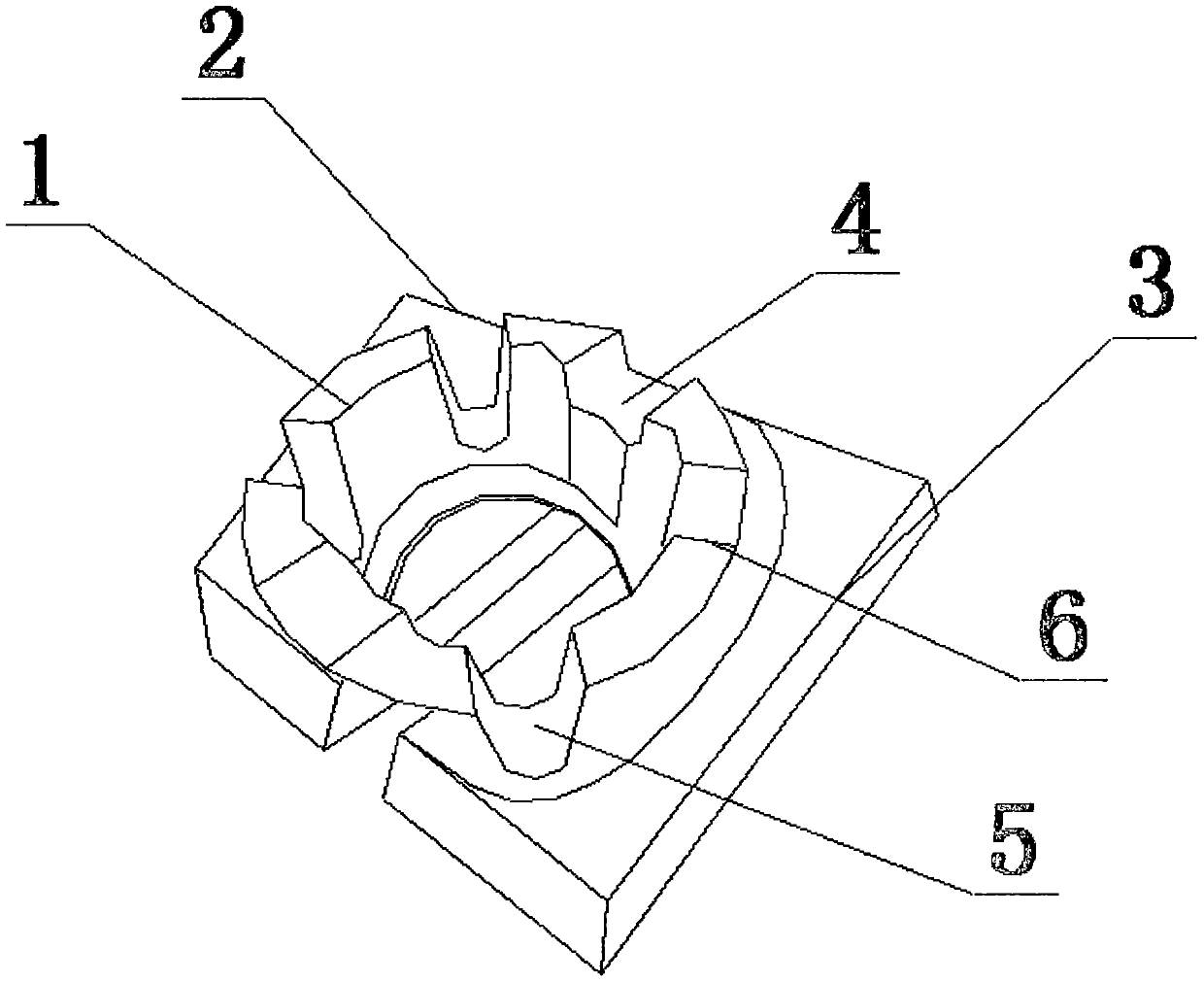

[0018] Such as figure 1 As shown, a tooling tool for pulling keys with fork-end teeth on the end face of a drive shaft includes a left base 2, a right base 3, and a positioning table 1. The positioning table 1 is cylindrical, and the positioning table 1 The left base 2 and the right base 3 are connected below. The upper edge of the positioning table 1 is symmetrically provided with two U-shaped grooves A4, two U-shaped grooves B5, and two U-shaped grooves C6. The width of the U-shaped groove A4 is greater than that of the U-shaped groove B5 and U-shaped groove C6, and the depth of the U-shaped groove A4 is smaller than that of the U-shaped groove B5 and U-shaped groove C6; the U-shaped groove B5 and U-shaped groove C6 have the same specifications , The left base 2 and the right base 3 are symmetrically arranged below the positioning table 1.

[0019] A hydraulic clamping table is arranged above the positioning table 1.

[0020] The present invention adopts a positioning table, a ...

Embodiment 2

[0023] Such as figure 1 As shown, a tooling tool for pulling keys with fork-end teeth on the end face of a drive shaft includes a left base 2, a right base 3, and a positioning table 1. The positioning table 1 is cylindrical, and the positioning table 1 The left base 2 and the right base 3 are connected below. The upper edge of the positioning table 1 is symmetrically provided with two U-shaped grooves A4, two U-shaped grooves B5, and two U-shaped grooves C6. The width of the U-shaped groove A4 is greater than that of the U-shaped groove B5 and U-shaped groove C6, and the depth of the U-shaped groove A4 is smaller than that of the U-shaped groove B5 and U-shaped groove C6; the U-shaped groove B5 and U-shaped groove C6 have the same specifications , The left base 2 and the right base 3 are symmetrically arranged below the positioning table 1.

[0024] The positioning table 1 and the left base 2, the positioning table 1 and the right base 3 are all welded.

[0025] Both the left ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com