Weather-proof gas shield welding wire capable of being welded with large current

A technology of gas shielded welding and high current, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem of high cost, achieve the effect of reducing cost and expanding the application area

Inactive Publication Date: 2018-03-06

张宇

View PDF1 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

But the prior art has the following deficiencies: 1) It is used for welding with a current below 280A; 2) It is basically designed with Cr-Cu-Ni alloy, and the cost is high

Weather-resistant gas-shielded welding wire suitable for high-current welding above 300A has not been reported

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-9

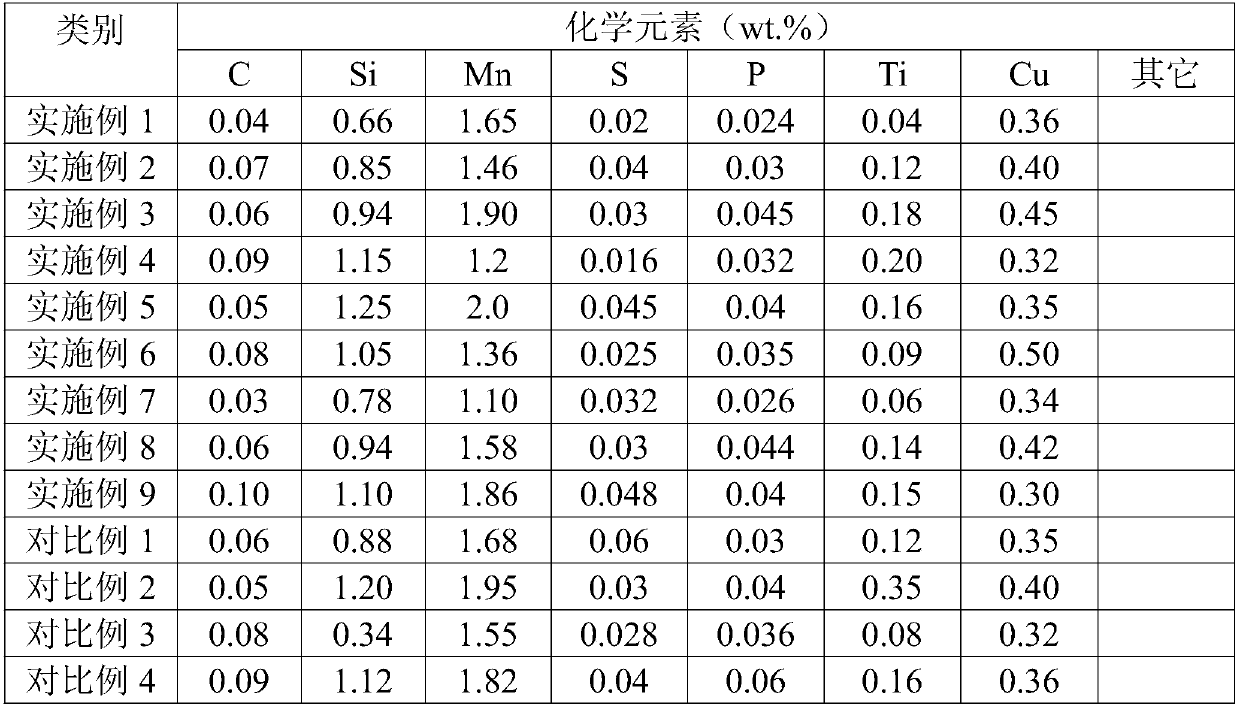

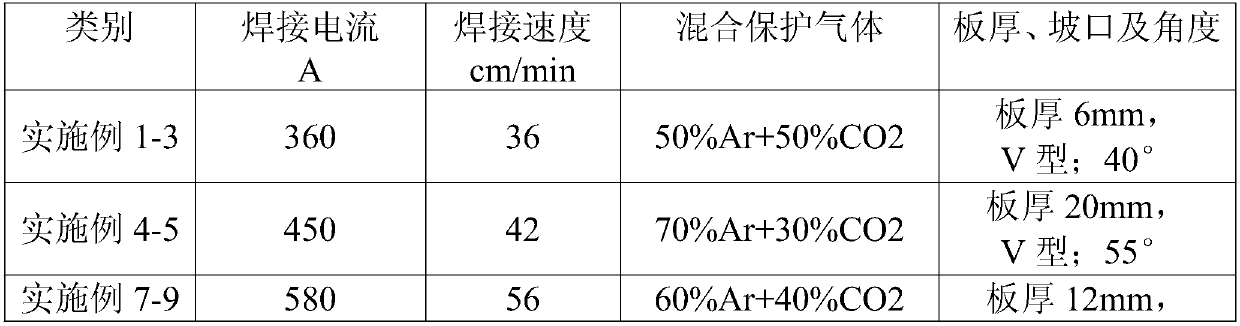

[0035] The chemical composition of the welding wire is shown in Table 1, the welding process is shown in Table 2, and the welding process performance is shown in Table 3.

[0036] After welding, no defects such as cracks and lack of fusion were found through non-destructive inspection and structural observation. The surface of the weld bead is smooth.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a weather-resistant gas-shielded welding wire capable of high-current welding. The chemical composition of the welding wire is: C ≤ 0.1%, Si 0.65-1.35%, Mn 1.0-2.0%, S 0.01-0.05%, P 0.01‑0.05%, Ti 0.02~0.3%, Cu 0.2‑0.5%, and the balance is Fe and impurity elements. With an inert gas mixture of 50% or more, the wire can be used for high-speed welding with a current of 300-600A and a speed of 30-60cm / min. The technology can be applied to the welding of ultra-high-strength steel plates in fields such as engineering machinery, buildings and bridges.

Description

technical field [0001] The invention relates to a weather-resistant gas-shielded welding wire, which belongs to the technical field of welding materials, in particular to a solid-core welding wire for gas-shielded welding that can adapt to high-current welding Background technique [0002] The use of weathering steel can avoid protective coating, shorten construction period and reduce production cost. At present, weather-resistant steel is gradually being applied in large-scale welded structures, such as bridges, buildings, etc.; and the large-scale application of such steel plates is inseparable from the weather-resistant gas shielded welding wire used for welding. [0003] The weather-resistant gas-shielded welding wire needs to meet the general mechanical properties, and its welded joints should have the same weather resistance as the base metal. Existing technologies 200310108200.0, 201410013357.x, 200710010787.x, 200810047484.x, 200910187781.9 and 201310057555.5 provid...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K35/30

CPCB23K35/3053

Inventor 张宇

Owner 张宇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com