Pipe fitting end polishing device

A technology for pipe fittings and ends, which is applied in the field of pipe fitting end grinding devices, which can solve the problems of welding quality influence, difficulty in ensuring grinding consistency, grinding quality, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

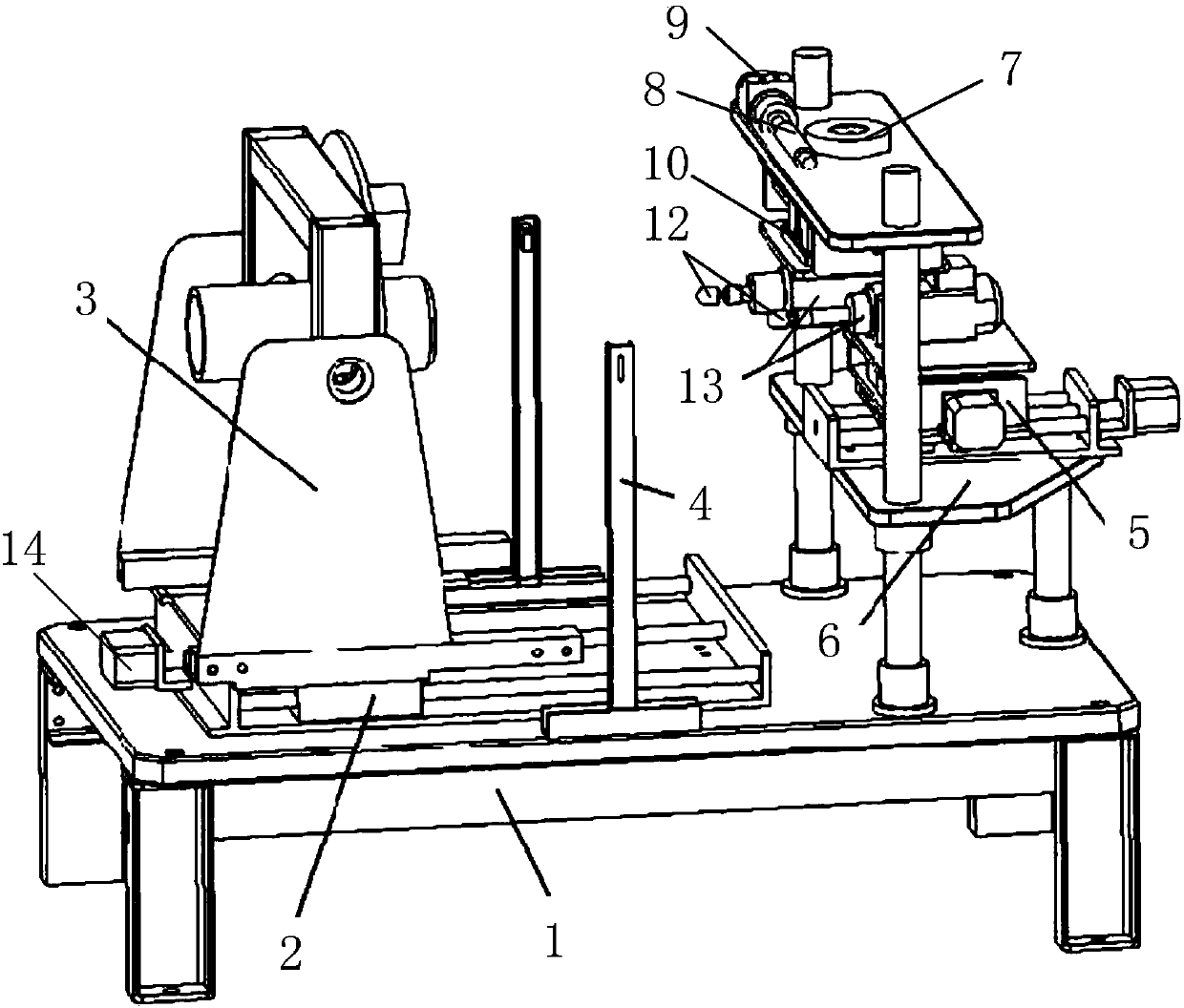

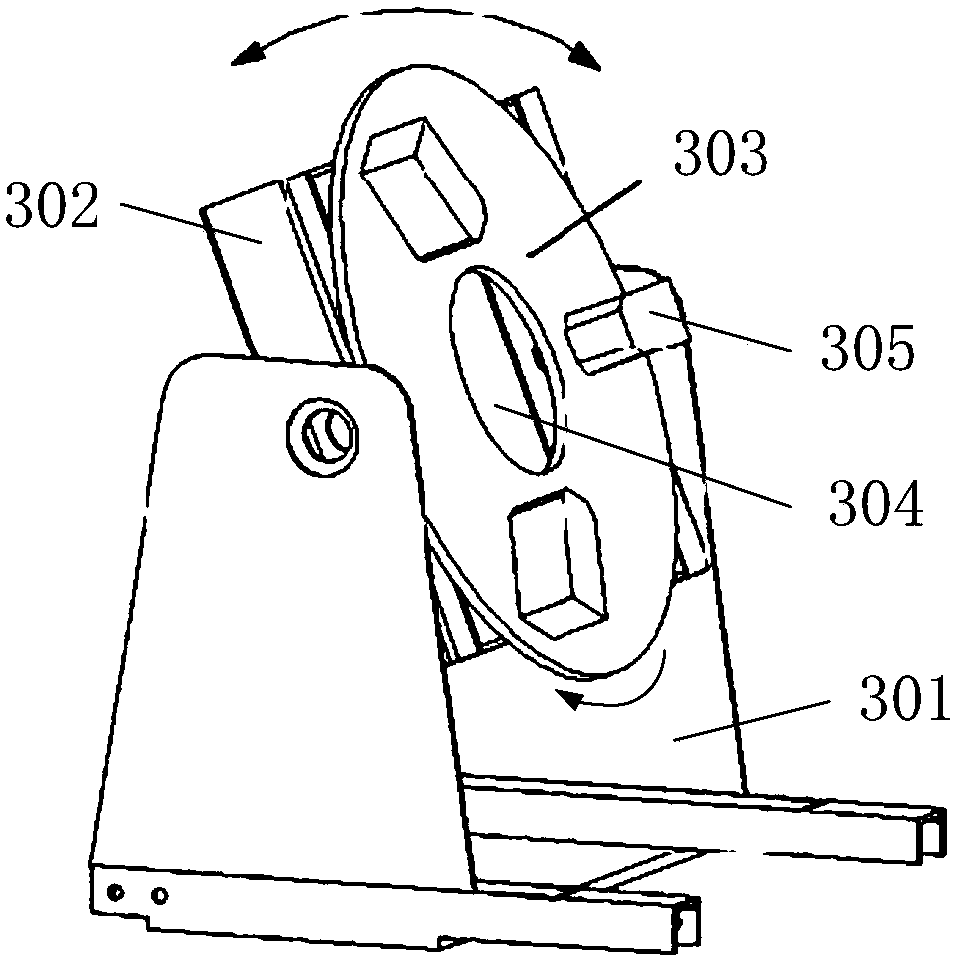

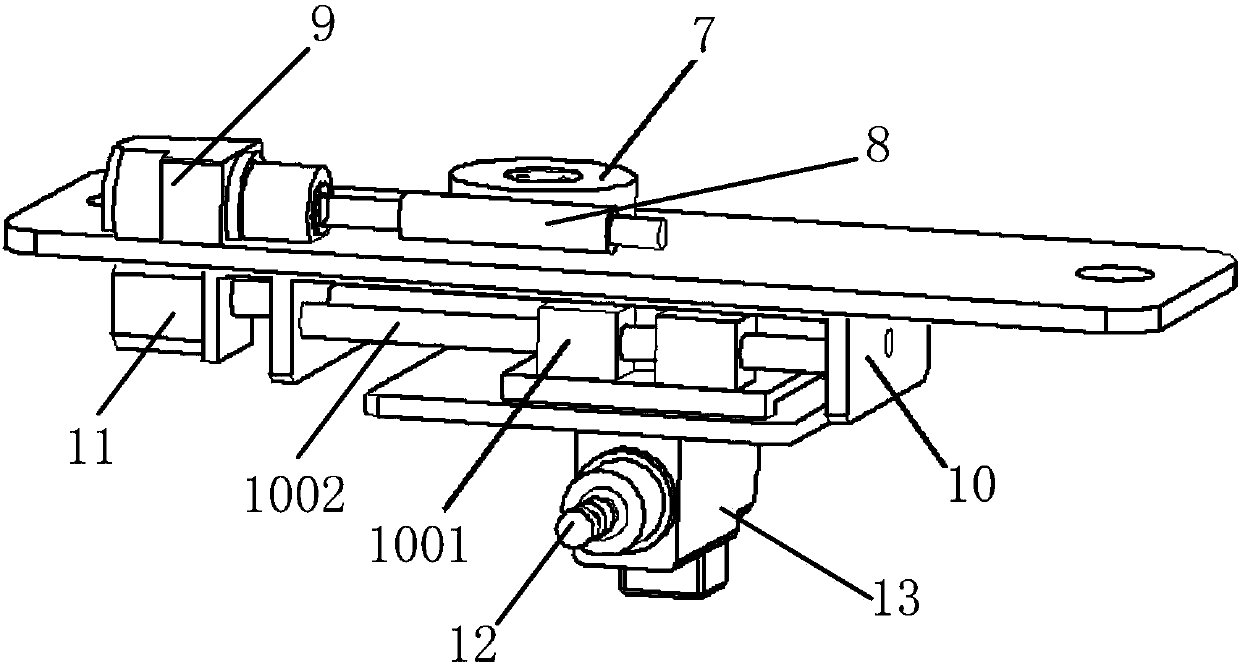

[0019] The pipe fitting end grinding device includes a base 1, and an overturning clamping table 3, an in-position detection device 4, an outer circle grinding mechanism, and an inner circle grinding mechanism, which are sequentially arranged on the base 1 from one side of the base 1 to the other side. and control system.

[0020] Such as figure 1 As shown, the flip clamping table 3 is arranged on the base 1 through the first guide rail slide table 2; specifically, the first guide rail slide table 2 includes a bottom plate fixed on the base 1, parallel and spaced spacers arranged on the bottom plate Two slide rails and two sliders respectively mounted on each slide rail; a first servo motor 14 is also arranged at the left edge of the base 1, and the output shaft of the first ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap