Testing and packaging integrated machine

A technology for testing packaging and all-in-one machines, applied in packaging, transportation packaging, packaging protection, etc., to achieve the effects of extending the service life, improving production efficiency, and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

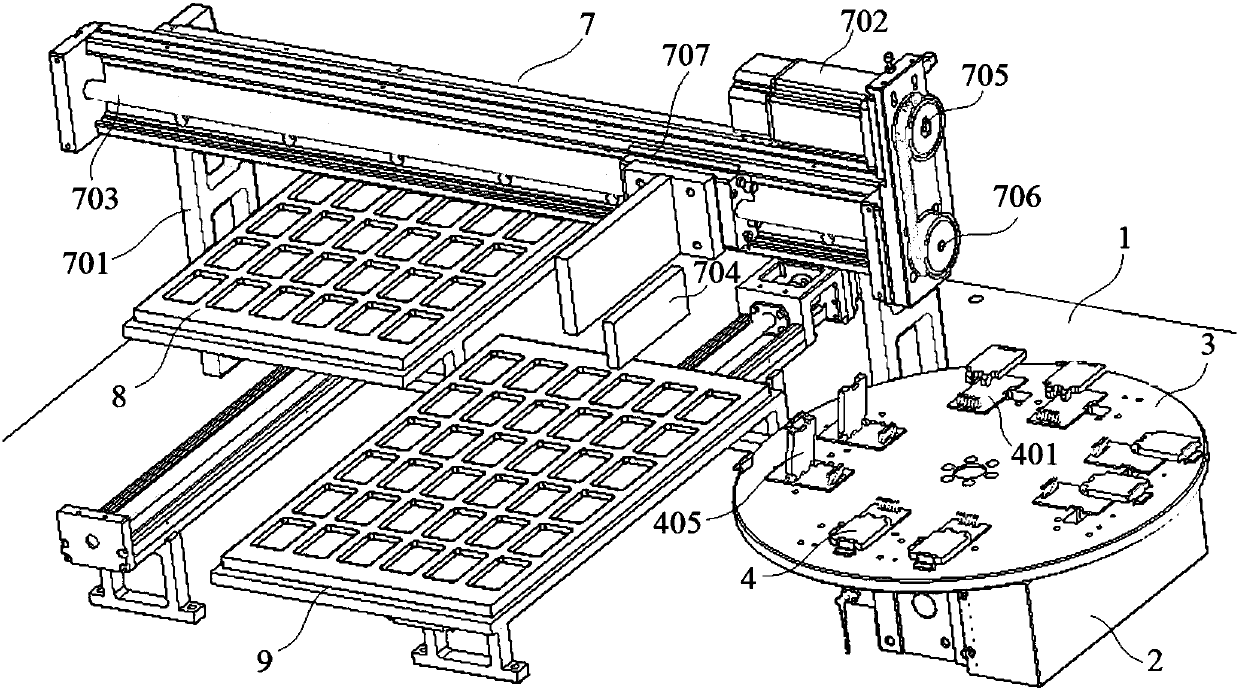

[0032] Embodiment 1: A test and packaging all-in-one machine, including a base plate 1, a turntable seat 2, a turntable 3, several test carriers 4, an opening mechanism 5 and a packaging mechanism 6, the turntable seat 2, the opening mechanism 5 and the packaging mechanism 6 are all fixedly installed on the upper surface of the bottom plate 1, the turntable 3 is rotatably arranged above the turntable seat 2, and the plurality of test carriers 4 are evenly arranged on the upper surface of the turntable 3 along the circumferential direction;

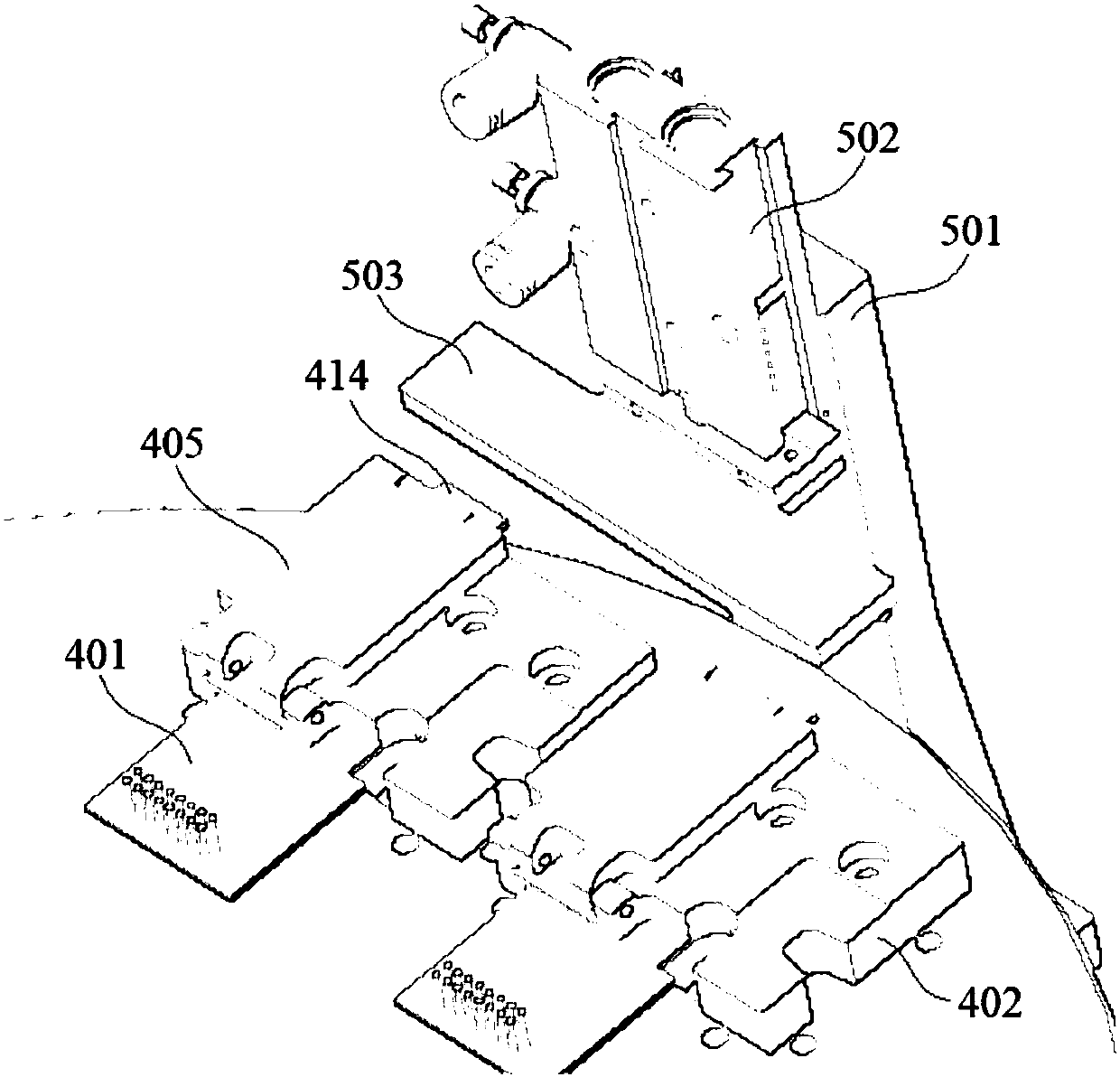

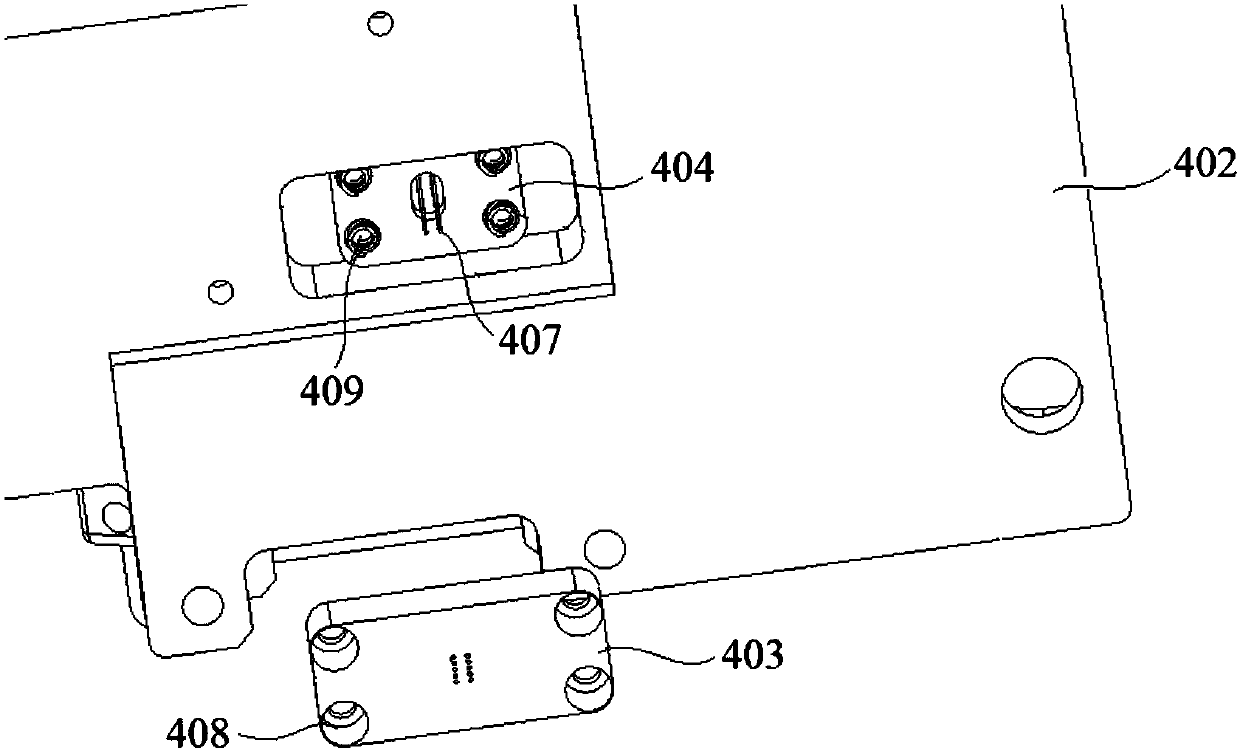

[0033] The test carrier 4 further includes a PCB board 401, a carrier board 402, a test board 403, a test seat 404 and a pressure plate 405, the pressure plate 405 is movably connected to the carrier board 402 through a mounting handle, and the test seat 404 is embedded in the carrier board In the through hole of 402, the test board 403 is installed on the lower surface of the carrier board 402 and is located below the test seat 404, the PC...

Embodiment 2

[0040] Embodiment 2: A testing and packaging all-in-one machine, including a bottom plate 1, a turntable seat 2, a turntable 3, several test carriers 4, an opening mechanism 5 and a packaging mechanism 6, the turntable seat 2, the opening mechanism 5 and the packaging mechanism 6 are all fixedly installed on the upper surface of the bottom plate 1, the turntable 3 is rotatably arranged above the turntable seat 2, and the plurality of test carriers 4 are evenly arranged on the upper surface of the turntable 3 along the circumferential direction;

[0041] The test carrier 4 further includes a PCB board 401, a carrier board 402, a test board 403, a test seat 404 and a pressure plate 405, the pressure plate 405 is movably connected to the carrier board 402 through a mounting handle, and the test seat 404 is embedded in the carrier board In the through hole of 402, the test board 403 is installed on the lower surface of the carrier board 402 and is located below the test seat 404, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com