Liquefied natural gas re-condensation device

A technology for liquefied natural gas and recondensation, which is applied in the fields of gas fuel, petroleum industry, fuel, etc., can solve the problems of low recondensation efficiency of boil-off gas and difficult pressure control, and achieves improved condensation efficiency, easy control, improved stability and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

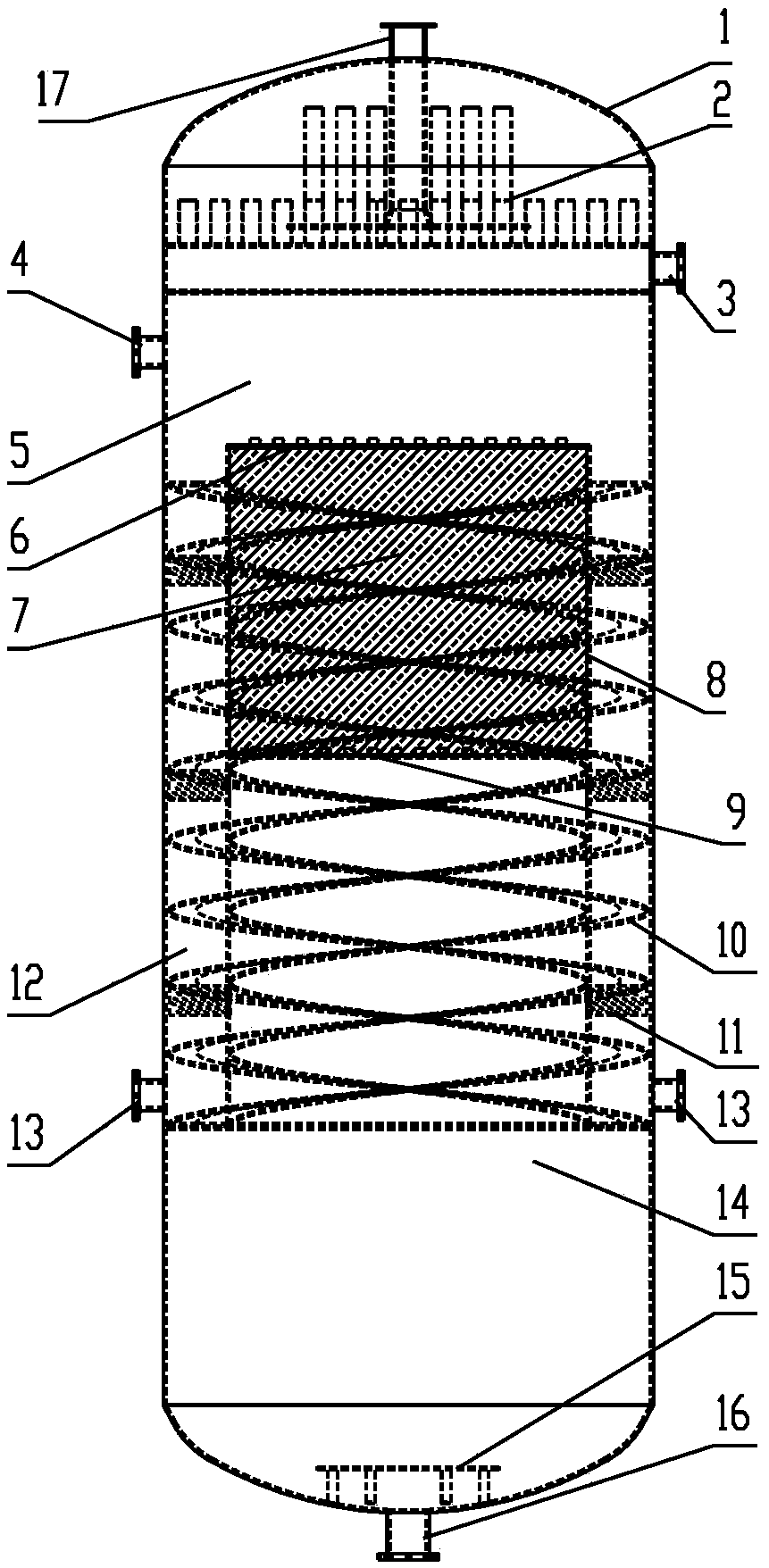

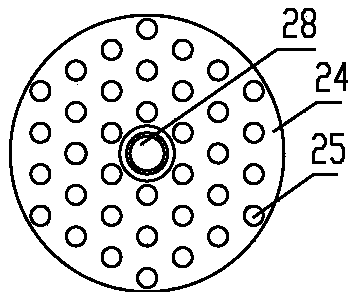

[0035] Depend on figure 1 It can be seen that the liquefied natural gas recondensation device provided by the present invention is a vertical structure, and from top to bottom, the outer cylinder 1, the LNG uniform distributor 2, the non-condensable gas discharge pipe 3, the BOG upper inlet pipe 4, the gas-liquid Mixing space 5, packing top plate 6, packing 7, inner cylinder 8, packing bottom plate 9, spiral lift gas plate 10, BOG uniform distribution plate 11, annular space 12, BOG bottom inlet pipe 13, LNG liquid phase space 14, vortex prevention Baffle plate 15, LNG outlet pipe 16.

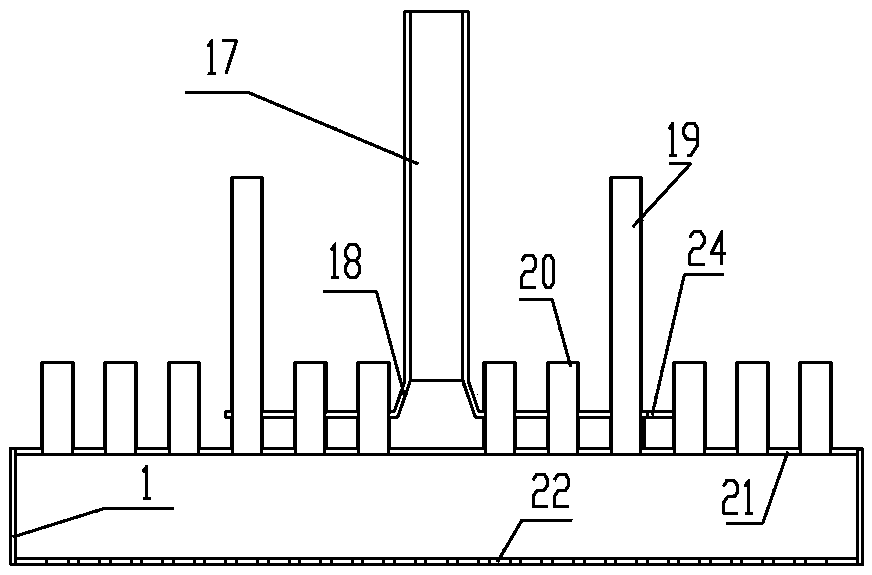

[0036] The LNG distributor 2 is arranged on the upper part of the outer cylinder 1, the upper end of the LNG inlet pipe 17 passes through the top of the outer cylinder 1 and is exposed outside the outer cylinder 1, and the non-condensable gas discharge pipe 3 is arranged on the primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com