A method for the overall layout of an ion adsorption type rare earth separation plant

A kind of ion adsorption type, rare earth technology, applied in the field of factory layout, can solve the problems of large drop, difficult to protect product intellectual property rights, etc., and achieve the effect of efficient supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

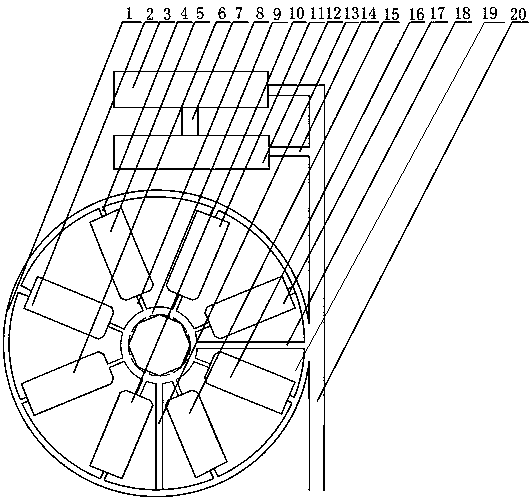

[0016] see figure 1 , the present invention is a method for the overall layout of an ion-adsorption type rare earth separation plant, including an ion-adsorption type rare earth in-situ leaching raw material pool 3, a leaching mother liquor pool 12, and a main building 19 arranged in steps.

[0017] There is a main connecting channel 20 on one side of the ion-adsorption type rare earth in-situ leaching raw material pool 3 , the leaching mother liquor pool 12 , and the main building 19 .

[0018] The ion-adsorption type rare earth in-situ leaching raw material pool 3 and the leaching mother liquor pool 12 are located above the main building 19 in a stepped manner, and the ion-adsorption rare earth in-situ leaching raw material pool 3 and the leaching mother liquor pool 12 are connected to the mother liquor pool channel 7 through the raw material pool .

[0019] The main building 19 includes extraction and separation workshops, finished rare earth oxide workshops, rare earth me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com