Washing machine footing with automatic leveling function and washing machine

An automatic leveling, washing machine technology, applied in the field of washing machines, can solve the problems of inconvenient operation, loud noise, heavy and other problems for users, and achieve the effects of improving comfort, reducing vibration and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

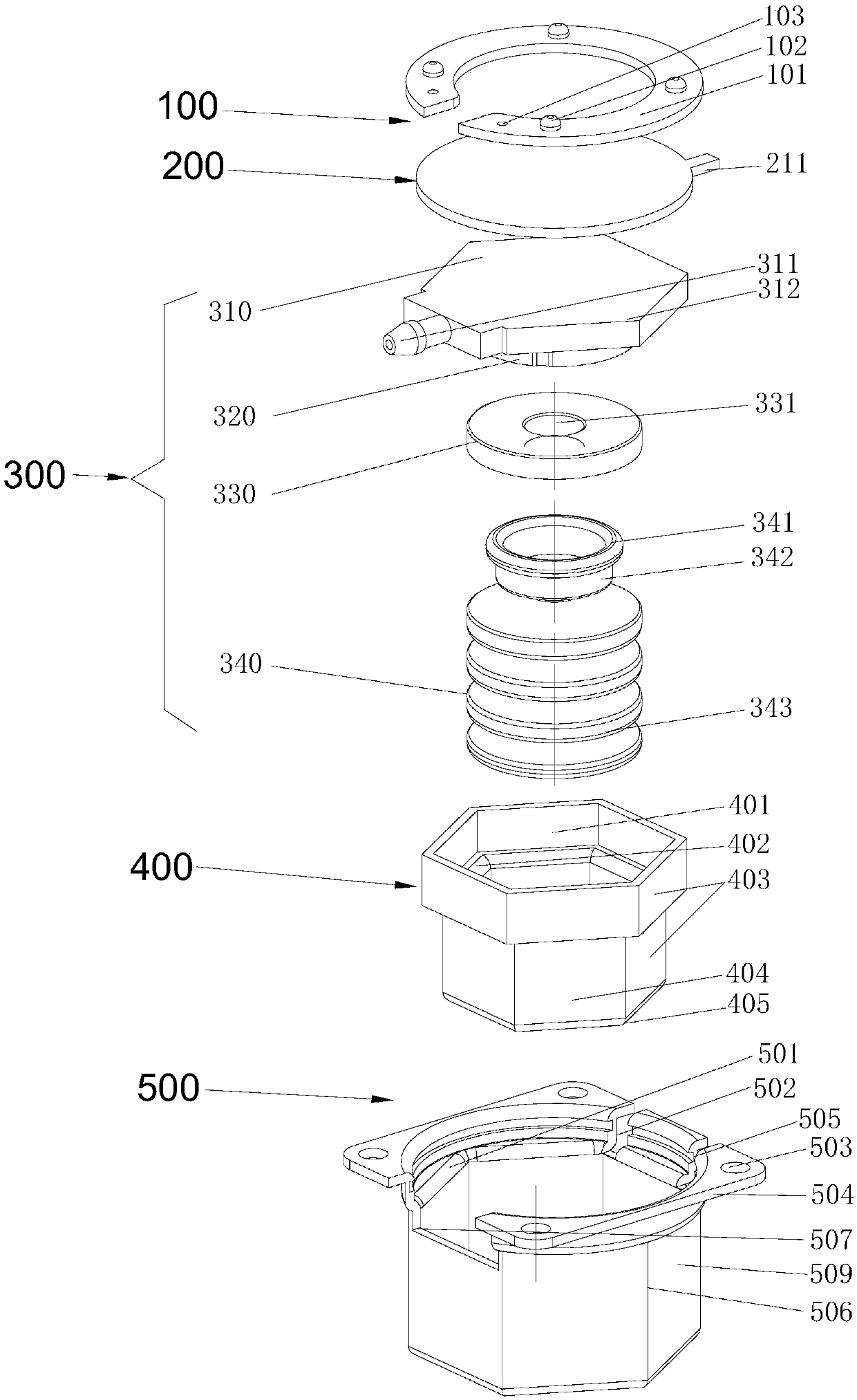

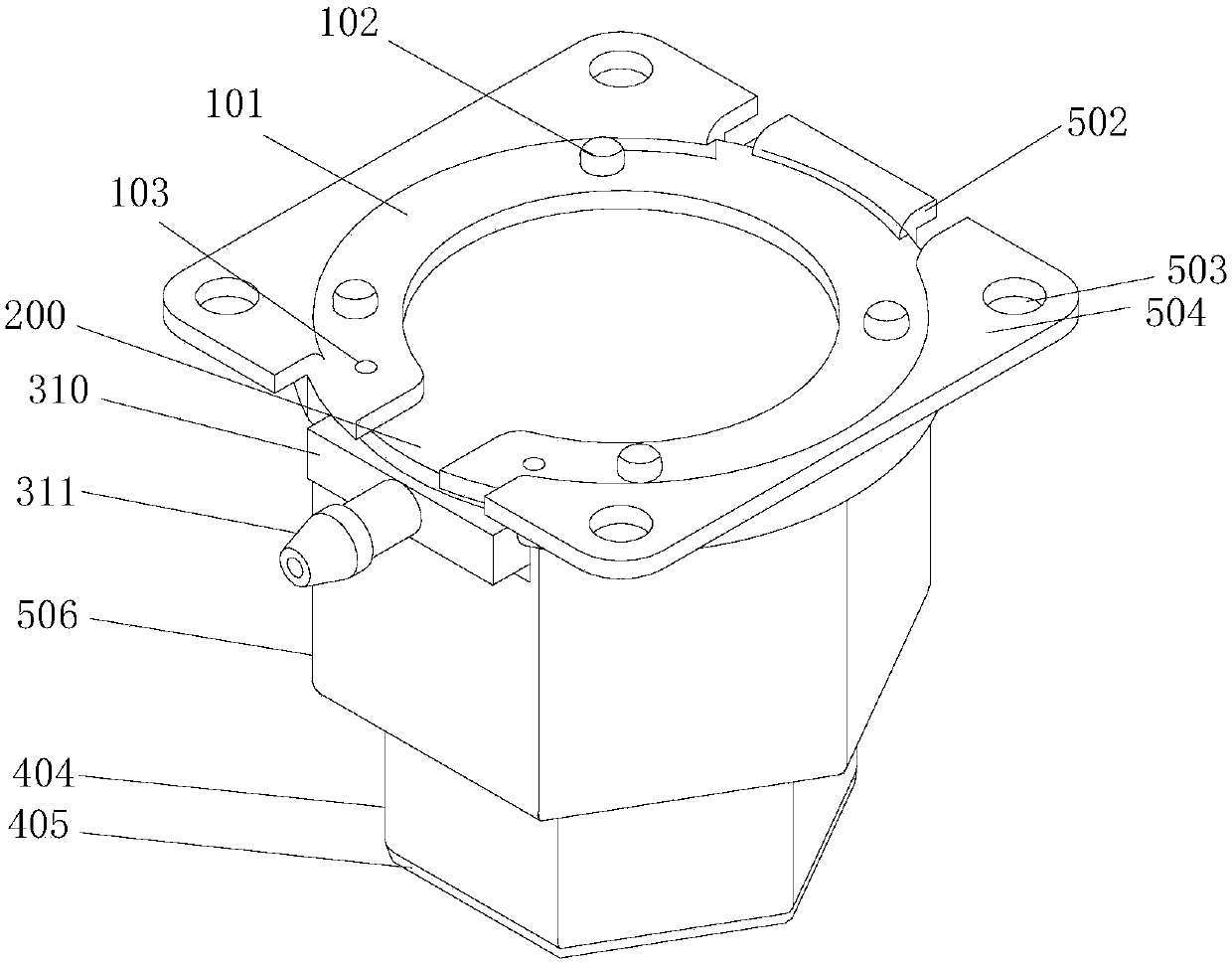

[0055] Such as Figure 1-6As shown, the foot of the washing machine with automatic leveling function in this embodiment includes:

[0056] Sheath 500;

[0057] The adjustment foot 400 is arranged in the sheath 500 and can move axially relative thereto;

[0058] And the flexible body assembly 300 is arranged in the adjustment foot 400 for containing the hydraulic medium;

[0059] One end of the flexible body assembly 300 is limitedly installed in the sheath 500, and the other end is a telescopic end acting on the adjustment foot 400;

[0060] The telescopic end of the flexible body assembly 300 expands and contracts under the action of the hydraulic medium to drive the adjustment foot 400 to move axially to achieve automatic leveling.

[0061] In this embodiment, the feet of the washing machine in this embodiment are arranged on the four corners of the bottom plate of the washing machine or at least four are evenly arranged along the circumferential direction of the bottom p...

Embodiment 2

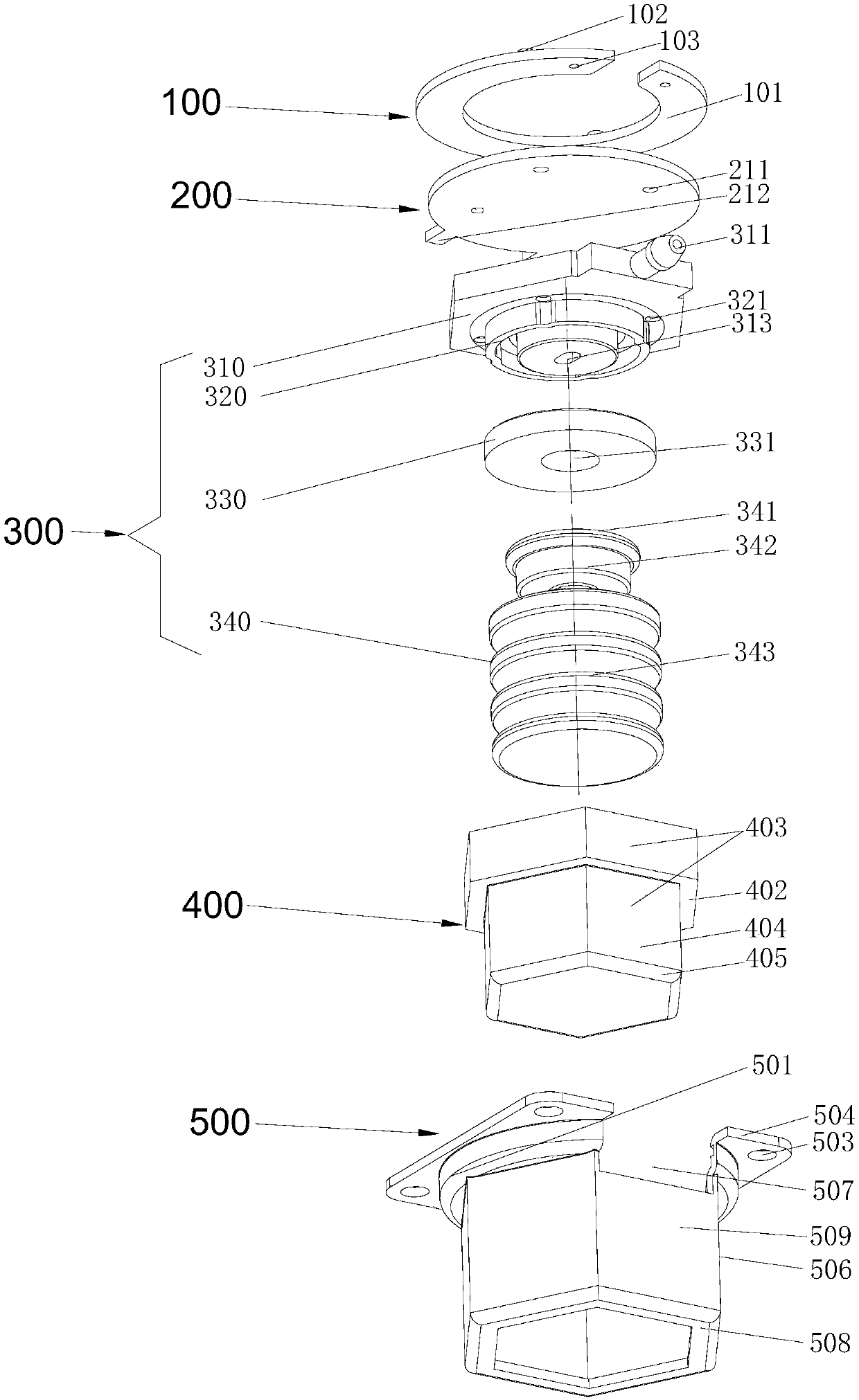

[0107] Such as Figure 1-6 As shown, the foot of the washing machine with automatic leveling function in this embodiment includes:

[0108] Sheath 500;

[0109] The adjusting foot 400 is arranged in the sheath 500 which can move axially, and the sheath 500 limits the circumferential rotation of the adjusting foot 400;

[0110] And the flexible body assembly 300 is arranged in the adjustment foot 400 for containing the hydraulic medium;

[0111] The flexible body assembly 300 includes a telescopic end acting on the adjustment foot 400 , and the telescopic end expands and contracts under the action of the hydraulic medium to drive the adjustment foot 400 to move axially to achieve automatic leveling.

[0112] The foot of the washing machine in this embodiment also limits the movement of the adjustment foot 400 so that it only moves up and down without rotation, so as to ensure the stability of the leveling process.

[0113] In order to realize the circumferential limit instal...

Embodiment 3

[0126] This embodiment relates to a method for assembling the foot of a washing machine:

[0127] Based on sheath 500

[0128] 1) Put the adjustment foot 400 with the rubber gasket into the upper opening of the sheath 500 .

[0129] Note that the limiting plane of the adjustment foot 400 corresponds to the limiting plane of the sheath 500 .

[0130] 2) Install the throttle diameter 342 of the oil bag 340 into the upper protection ring 330, insert the opening of the oil bag 340 into the raised part of the oil pressure plate 310 and place it at the seal groove 315, and press the pressure plate 320 against the oil bag 340 Through the opening of the opening, the screw or bolt passes through the installation hole 212 of the limit plate, the installation hole of the oil pressure plate and the installation hole 321 of the pressure plate, and then the oil bag 340, the upper protection ring 330, the pressure plate 320, and the oil pressure plate 310 are composed of a flexible body ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com