A method for protecting the water stop of an immersed tube tunnel

A technology of immersed tube tunnels and waterstops, which is applied in water conservancy projects, underwater structures, buildings, etc., and can solve problems such as high waterproof requirements, poor protection effects, and complicated disassembly and assembly, so as to reduce construction difficulty and save costs , The effect of fast disassembly and assembly operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

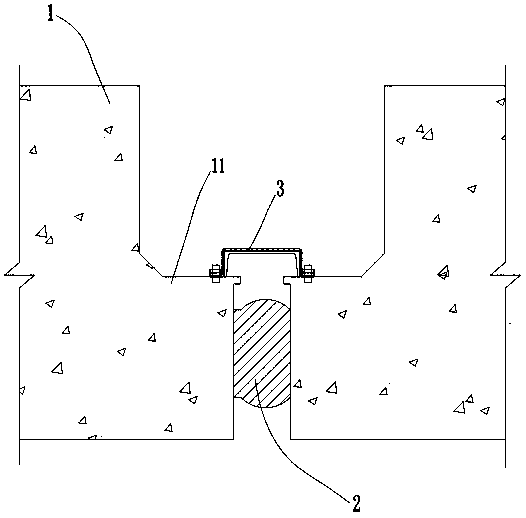

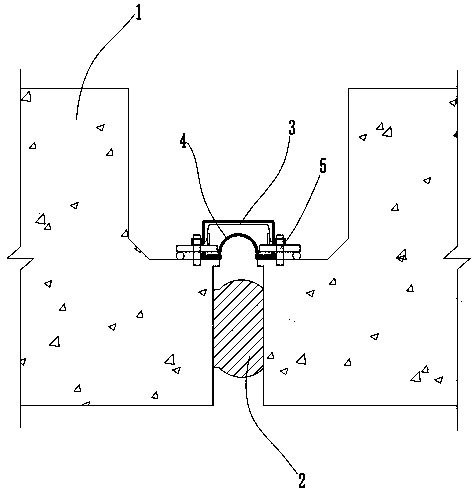

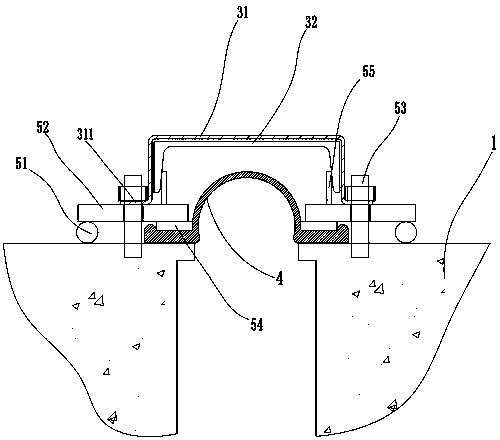

[0038] Such as Figure 1 to Figure 5 As shown, the portable immersed tube tunnel waterstop protection device in this embodiment includes a channel steel plate. The channel steel plate in this embodiment directly adopts channel steel 32, and the groove width of channel steel 32 is larger than the splicing of adjacent immersed tube joints. The seam size also includes the positioning ribs for fixing the channel steel 32 on the immersed tube joint, the positioning ribs are made of flexible material, so that the two sides of the channel steel 32 are respectively installed on the sinking bars on both sides of the splicing joint. on the pipe joint.

[0039] The immersed tube joints on both sides of the splicing joint are provided with special butt joint ends, and the threaded holes and bolt connection structures for installing the OMEGA waterstop will be set in advance on the adjacent immersed tube joint joints. The water belt protection device uses this structure to fix the two ends ...

Embodiment 2

[0050] Such as Figure 1 to Figure 5 As shown, according to the portable immersed tube tunnel waterstop protection device described in Embodiment 1, this embodiment provides a protection method for using the waterstop protection device for an immersed tube tunnel waterstop, including the following steps:

[0051] A. GINA waterstop 2 protection. After the GINA waterstop 2 is installed in place, empty the seawater and debris in the joint space of the pipe joint. Before the inner steel seal door of the pipe joint is removed, install a waterstop protection device at the joint of the pipe joint. ;

[0052] B. Carry out the removal operation of the steel seal door;

[0053] C. Install OMEGA waterstop 4, and install OMEGA waterstop 4 after removing the waterstop protection device;

[0054] D. OMEGA waterstop 4 protection, use the pressure plate of OMEGA waterstop 4 located at the pipe joint to set up the mounting frame, buckle the grooved steel plate on the mounting frame, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com