Dual radial sealing structure for compressor interstage

A compressor-stage, dual-stage technology, applied to components, mechanical equipment, machines/engines, etc. of elastic fluid pumping devices, can solve new problems such as reducing compressor life, inter-stage airflow temperature rise, and brush seals. Problems such as the difficulty in the application of the sealing structure to achieve the effect of reducing leakage flow and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

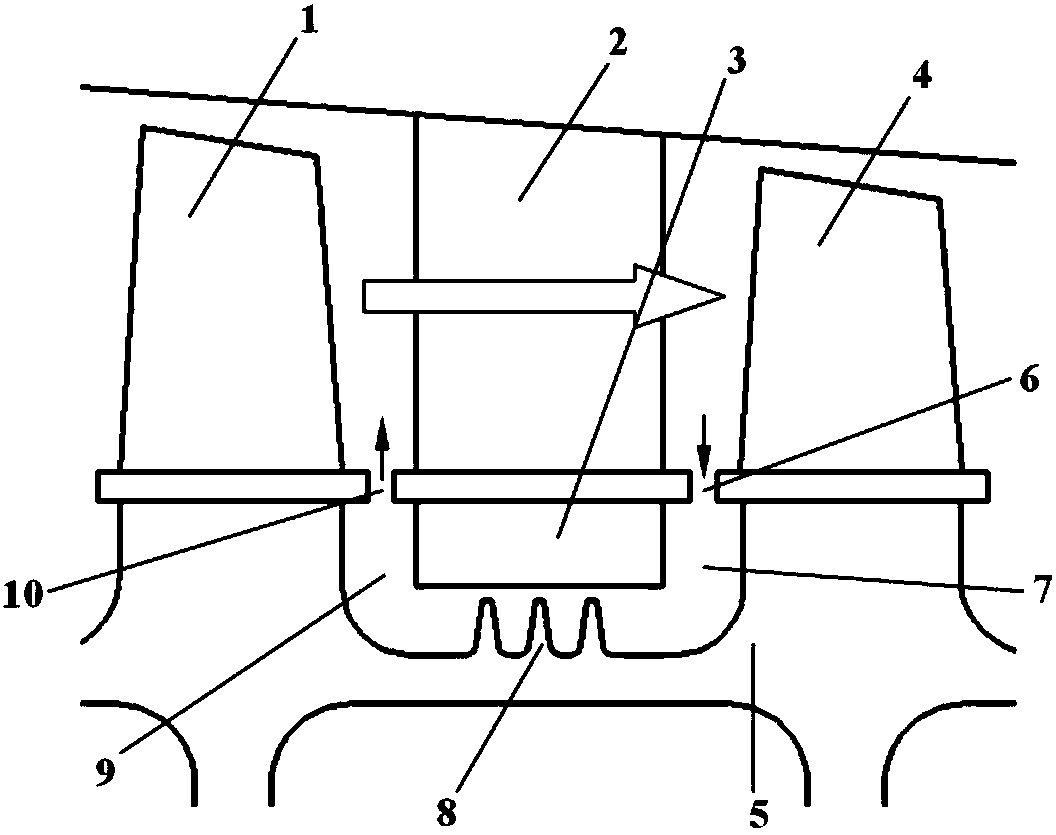

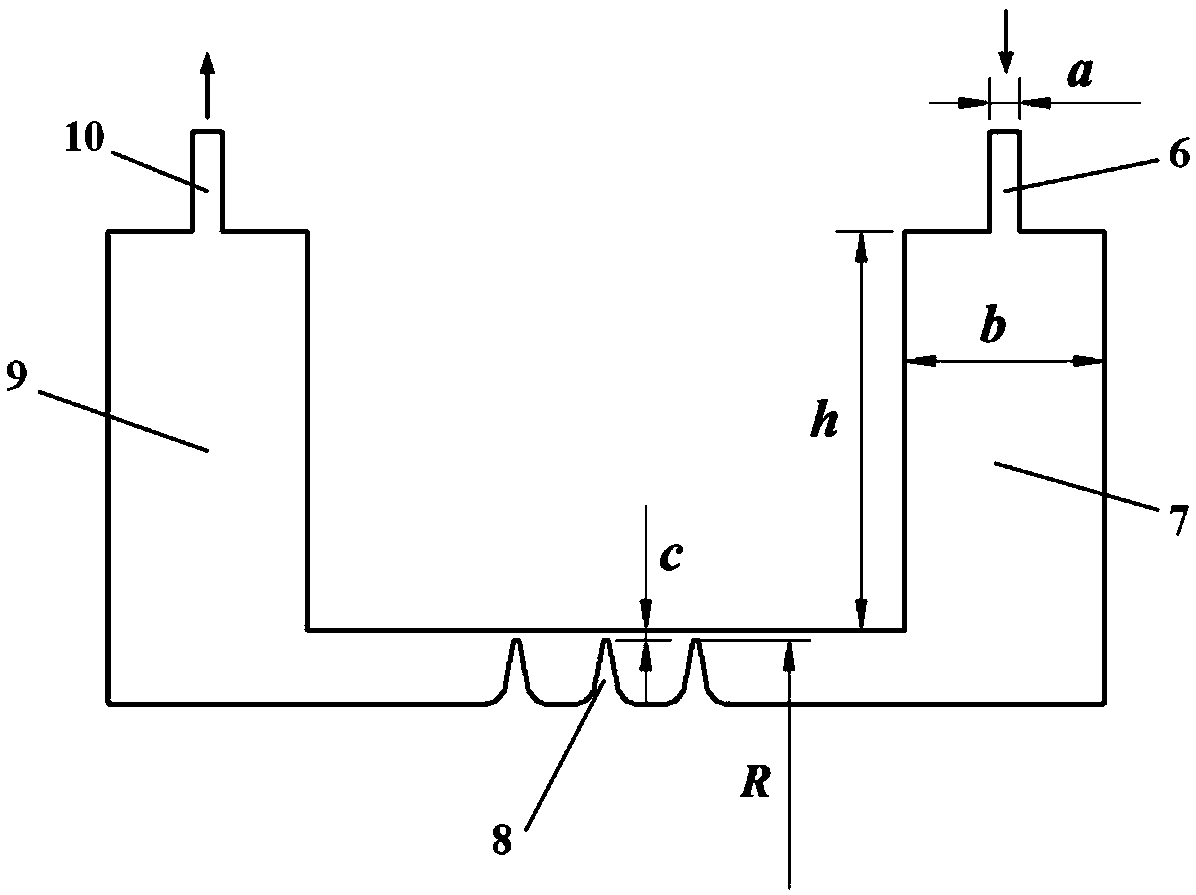

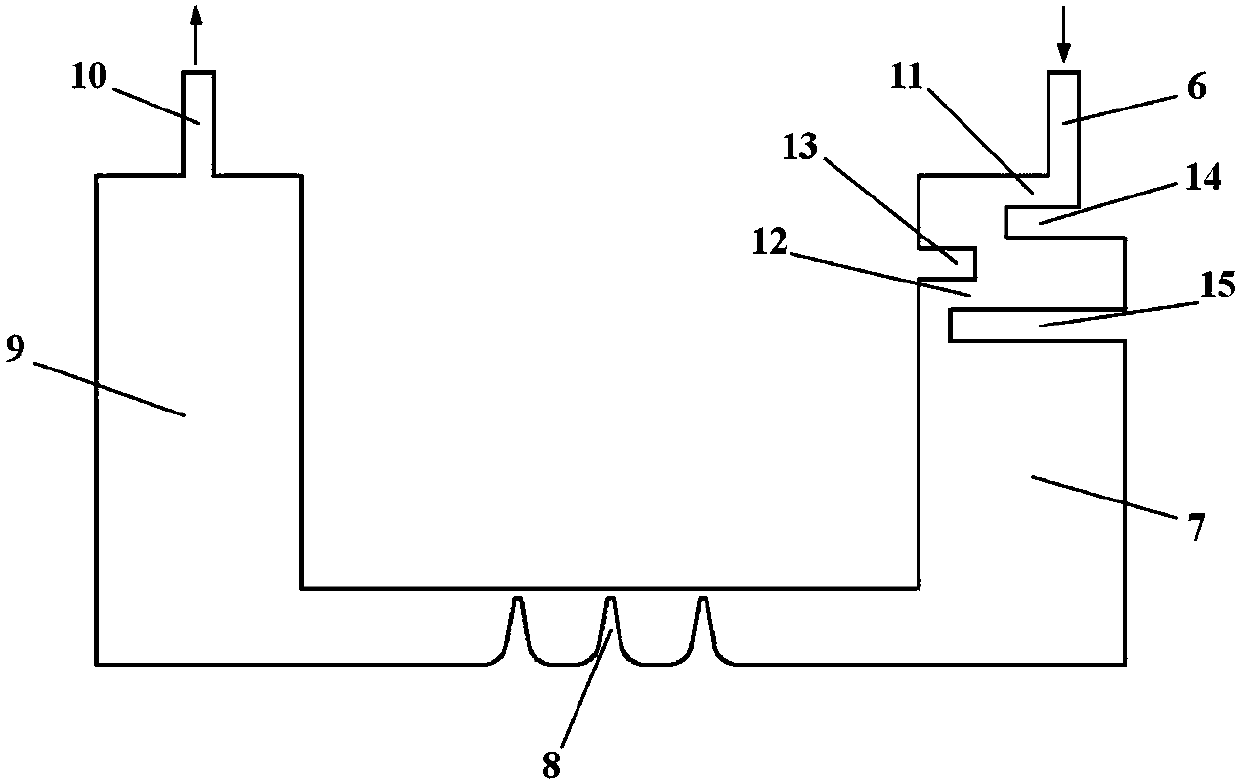

[0028] In this example, for a certain high-pressure compressor interstage structure, the difference in sealing performance between the conventional interstage structure and the interstage structure with double radial sealing is compared and analyzed.

[0029] The geometric parameters of the interstage structure are as follows:

[0030] The axial sealing gap a of the inlet and outlet is 1.5mm, the width b of the inlet and outlet rotary disc cavity is 10mm, the height h of the inlet and outlet rotary disc cavity is 20mm, the clearance c of the tooth top of the grate tooth is 0.5mm, and the radius R of the tooth top is 250mm .

[0031] According to the CFD numerical simulation, it can be obtained that when the speed is 8000rpm, Figure 5 The conventional interstage structure velocity streamline diagram shown and Figure 6 Velocity streamline diagram of interstage structure with double radial seal shown. From Figure 5 It can be seen from the figure that in the conventional in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com