A Method for Determining the Operating Force of Aircraft Hydraulic Brake Valve

A determination method, aircraft hydraulic technology, applied in the direction of fluid pressure actuators, mechanical equipment, servo motor components, etc., can solve the problem of inability to calculate the dynamic control force of the aircraft brake valve, the dynamic study of the control force characteristics of the hydraulic brake valve, and the inability to optimize And improve the pilot's braking control experience and other issues, to achieve the effect of improving the control experience, optimizing the control experience, and improving the control quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

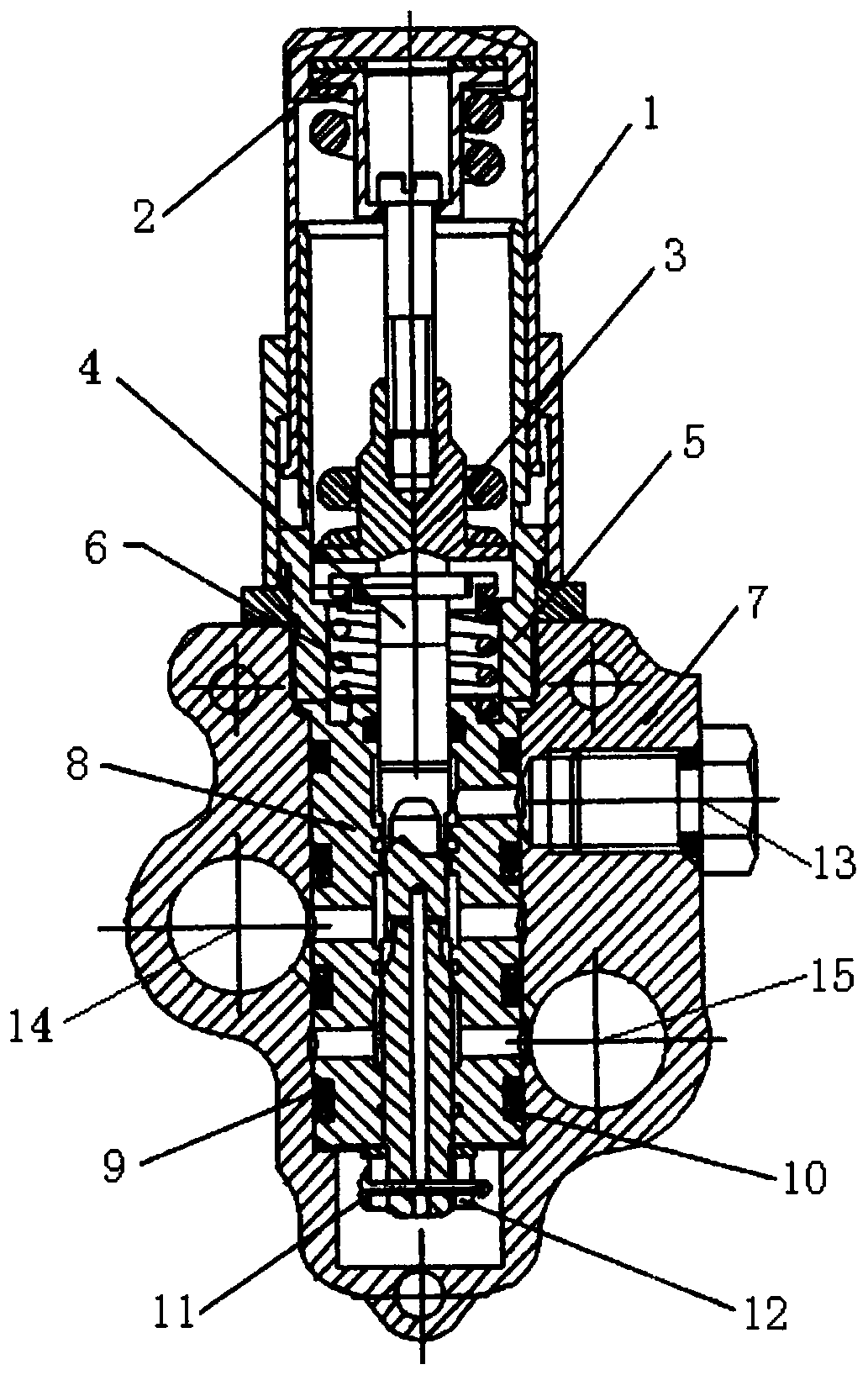

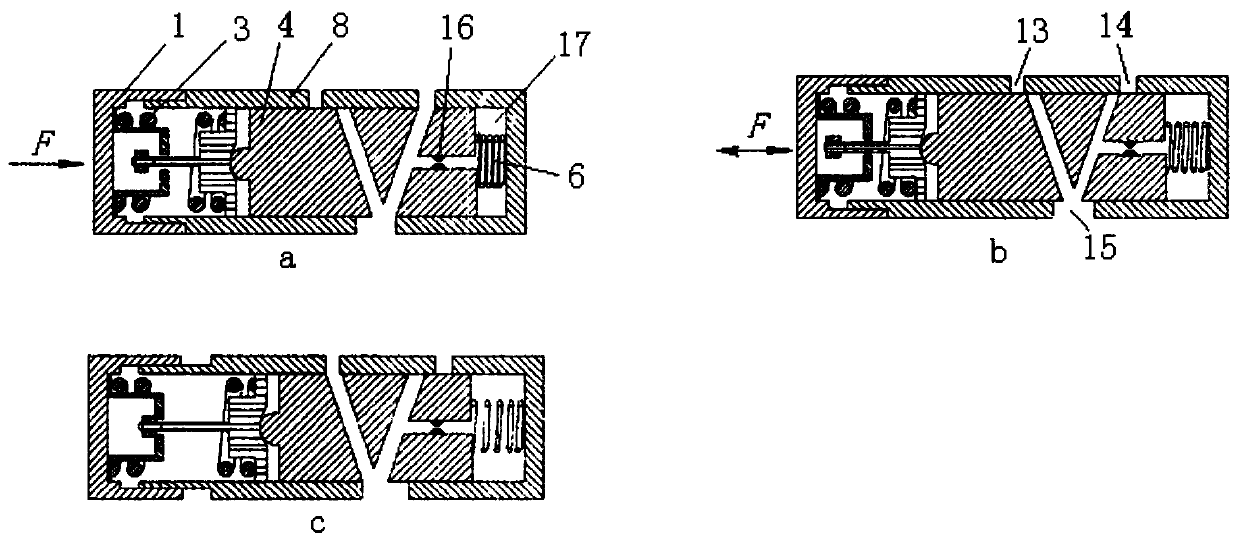

[0043] This embodiment is a calculation method for determining the required operating force according to the working stroke generated by the pilot's actual manipulation of the aircraft brake valve. The specific process is:

[0044] Step 1, determine the spool travel x:

[0045] Dynamic force analysis of the spool of the hydraulic brake valve during the braking operation. The force mentioned includes the preload F of the spring assembly t0 , the increased elastic force of the decompression spring assembly after being compressed, the reaction force of the hydraulic brake valve sensing pressure chamber, the elastic force of the return spring, the viscous resistance suffered by the spool, and the friction force F on the spool f ; The resultant force formed by the above-mentioned forces is equal to the inertial force of the spool. According to Newton's second law, the following mechanical equation is established by formula 1:

[0046]

[0047] Where: F t0 is the pretightening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com