Cutting traction equipment

A technology of equipment and cutting device, applied in metal processing equipment, clamping, supporting and other directions, can solve the problems of large volume, poor cutting accuracy and low efficiency of automatic cutting equipment, and achieve easy installation and later maintenance, convenient control, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

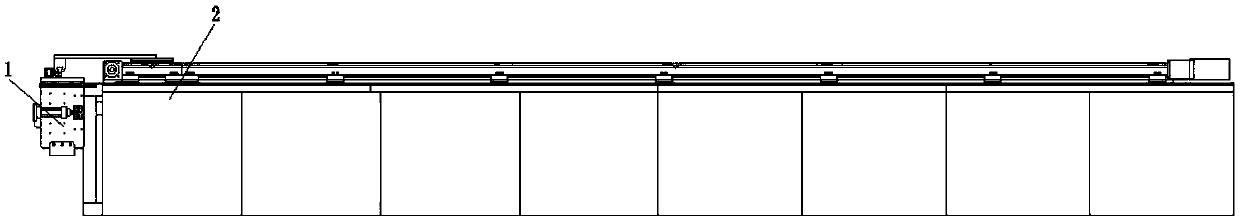

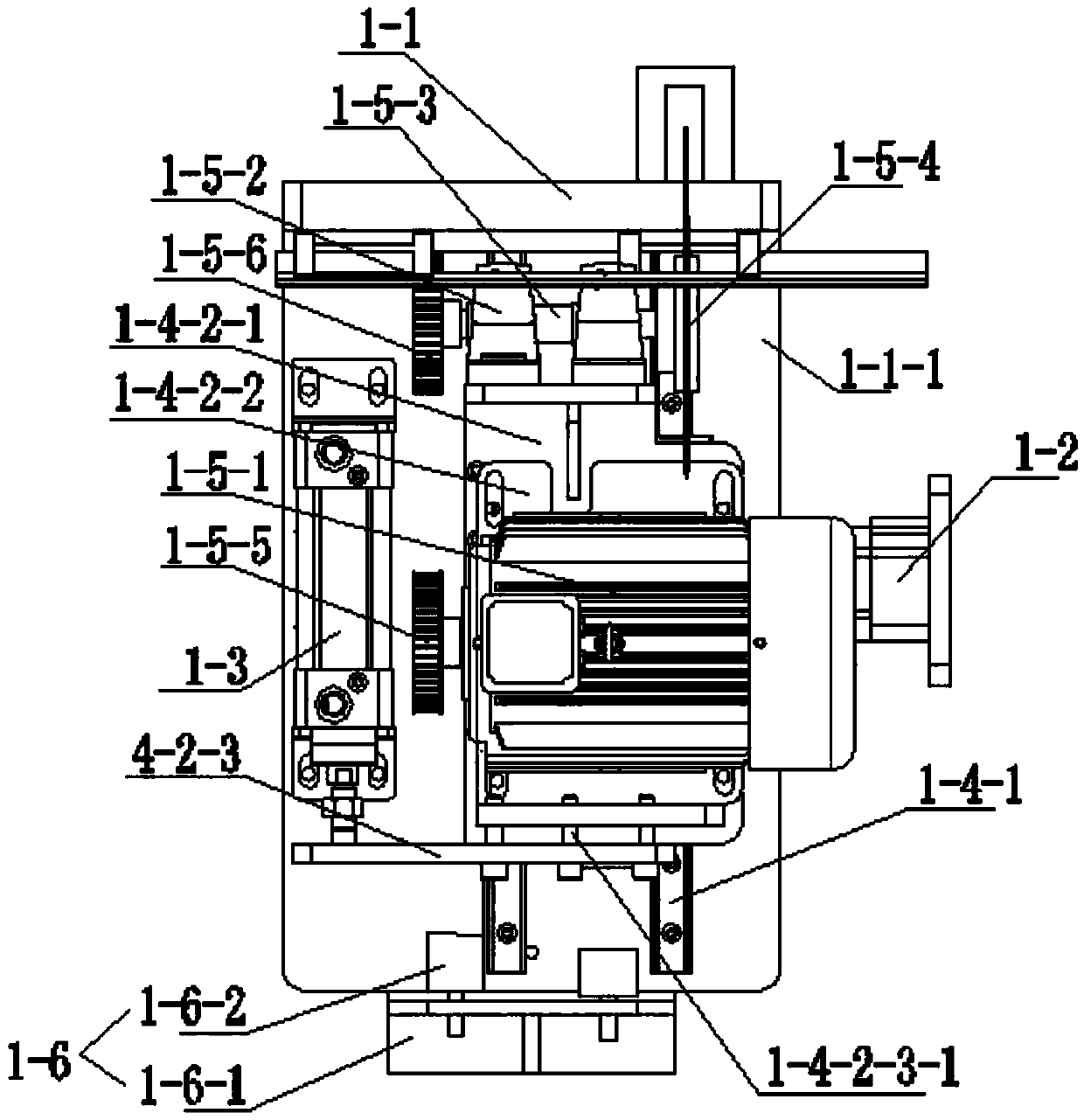

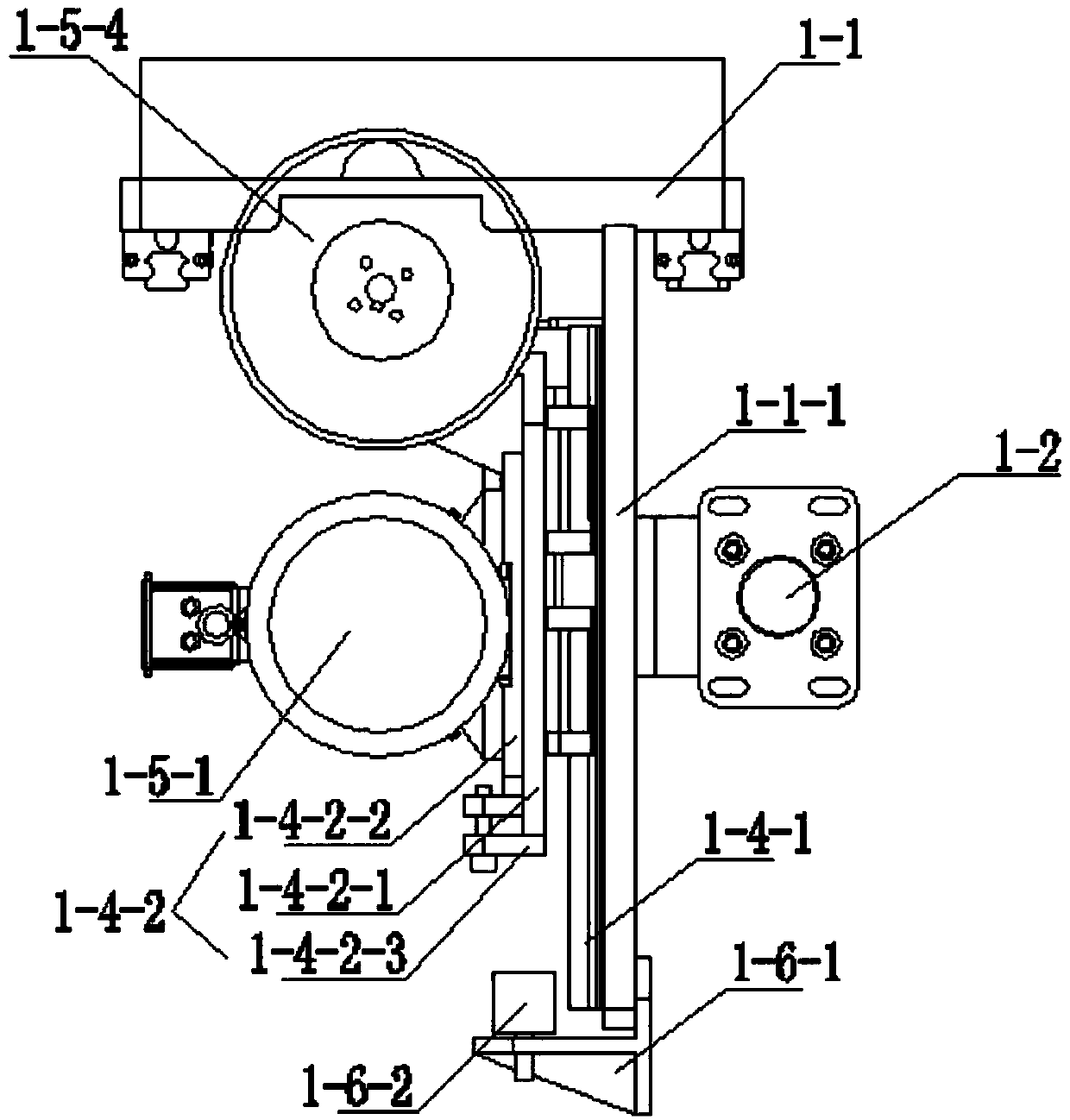

[0038] See Figure 1 to Figure 8 , the cutting and pulling device of this embodiment includes a cutting device 1 and a pulling device 2 .

[0039] The cutting device 1 includes a cutting table 1-1, a horizontal driving cylinder 1-2, a vertical driving cylinder 1-3, a sliding mechanism 1-4, a cutting mechanism 1-5 and a buffer mechanism 1-6. A mounting plate 1-1-1 extending downward is provided on the bottom surface of the cutting table 1-1. The laterally driven cylinder 1-2 drives the lateral displacement of the cutting table 1-1. The sliding mechanism 1-4 is located on the mounting plate 1-1-1. The cutting mechanism 1-5 is installed on the sliding mechanism 1-4. The vertical drive cylinder 1-3 drives the cutting mechanism 1-5 to move upwards along the sliding mechanism 1-4 and stretches out the top surface of the cutting table 1-1 to cut the material. The pulling device 2 pulls the material through the top surface of the cutting table 1-1.

[0040] The traction device 2 ...

Embodiment 2

[0054] See Figure 9 , This embodiment is basically the same as Embodiment 1, except that the linear module 2-2 includes a slide table 2-2-6, a screw rod 2-2-7 and a nut 2-2-8. Slide table 2-2-6 is fixed on the top surface of machine platform 2-1. The both sides of screw mandrel 2-2-7 are rotationally connected with the both sides of slide table 2-2-6, and the right side of screw mandrel 2-2-7 runs through the right side of slide table 2-2-6. The slide part 2-2-1 is slidingly connected with the slide rail of the slide table 2-2-6. The nut 2-2-8 is threadedly connected with the screw rod 2-2-7, and the bottom of the nut 2-2-8 is fixed with the sliding part 2-2-1. The output end of the worm gear reducer 2-4-2 of the traction drive mechanism 2-4 drives the screw mandrel 2-2-7 to rotate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com