Circulating water cooling system with tubing position correction function

A circulating water cooling and pipe technology, which is applied to household appliances, tubular objects, and other household appliances, can solve the problems of large cooling water consumption, waste of resources, misalignment of water nozzles, etc., to ensure cooling effect and facilitate precision The effect of regulating and cooling water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

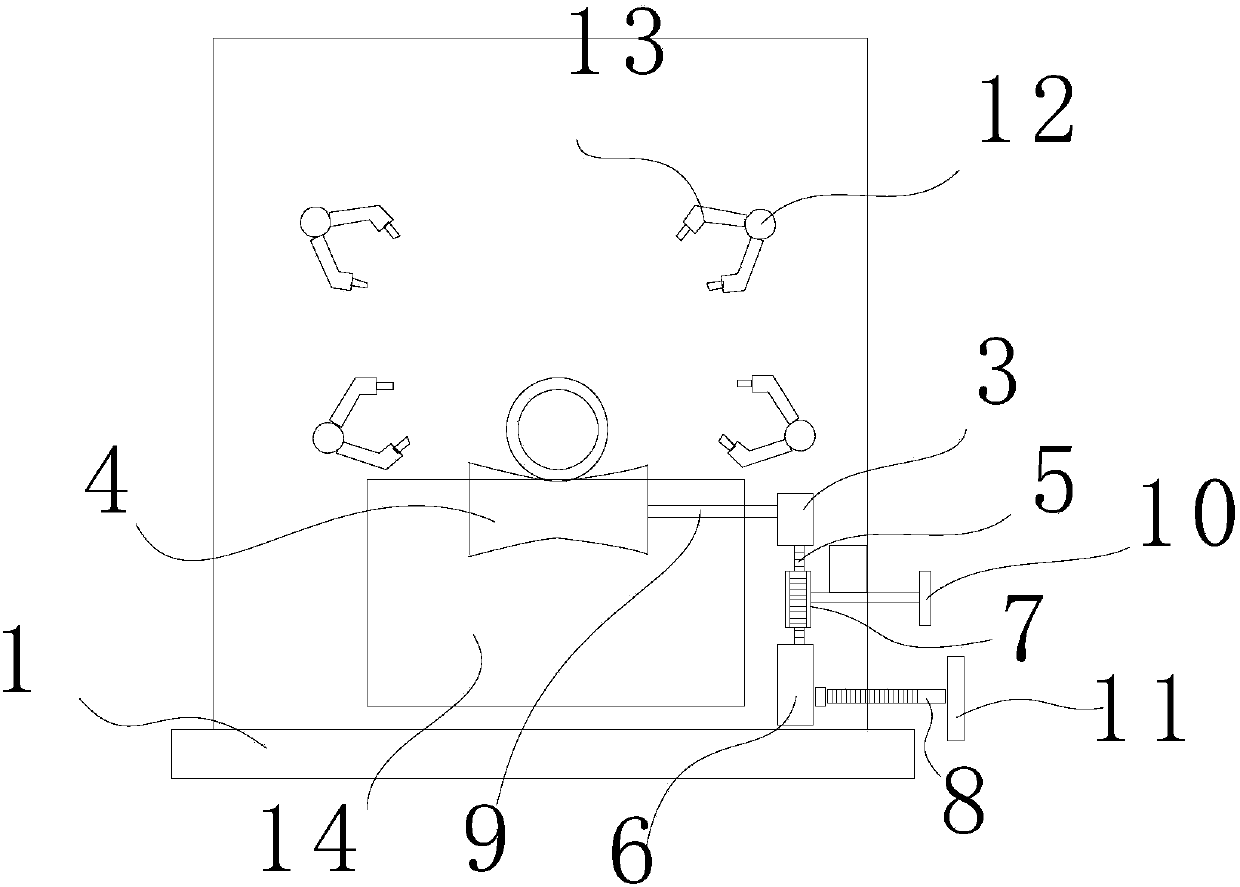

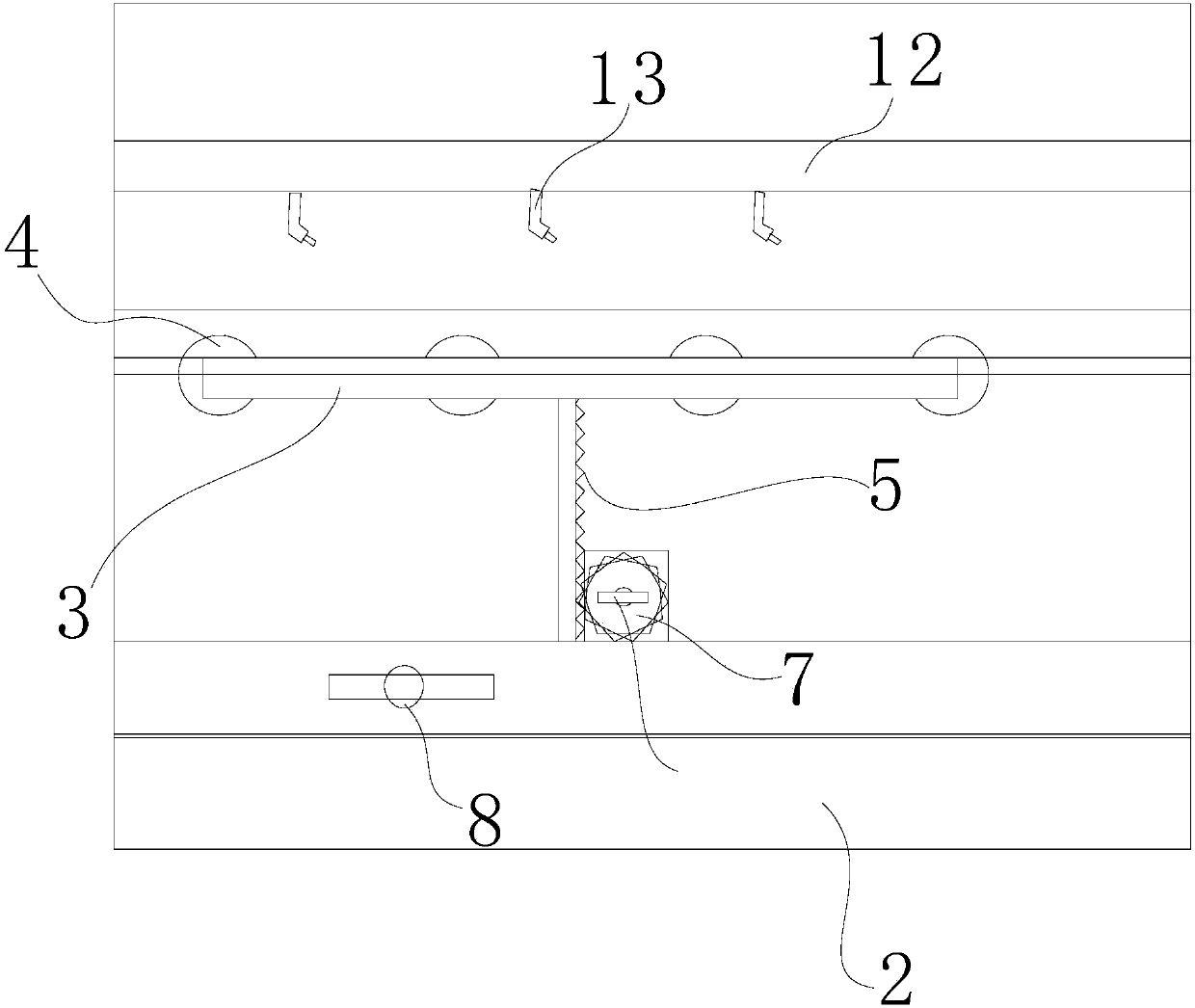

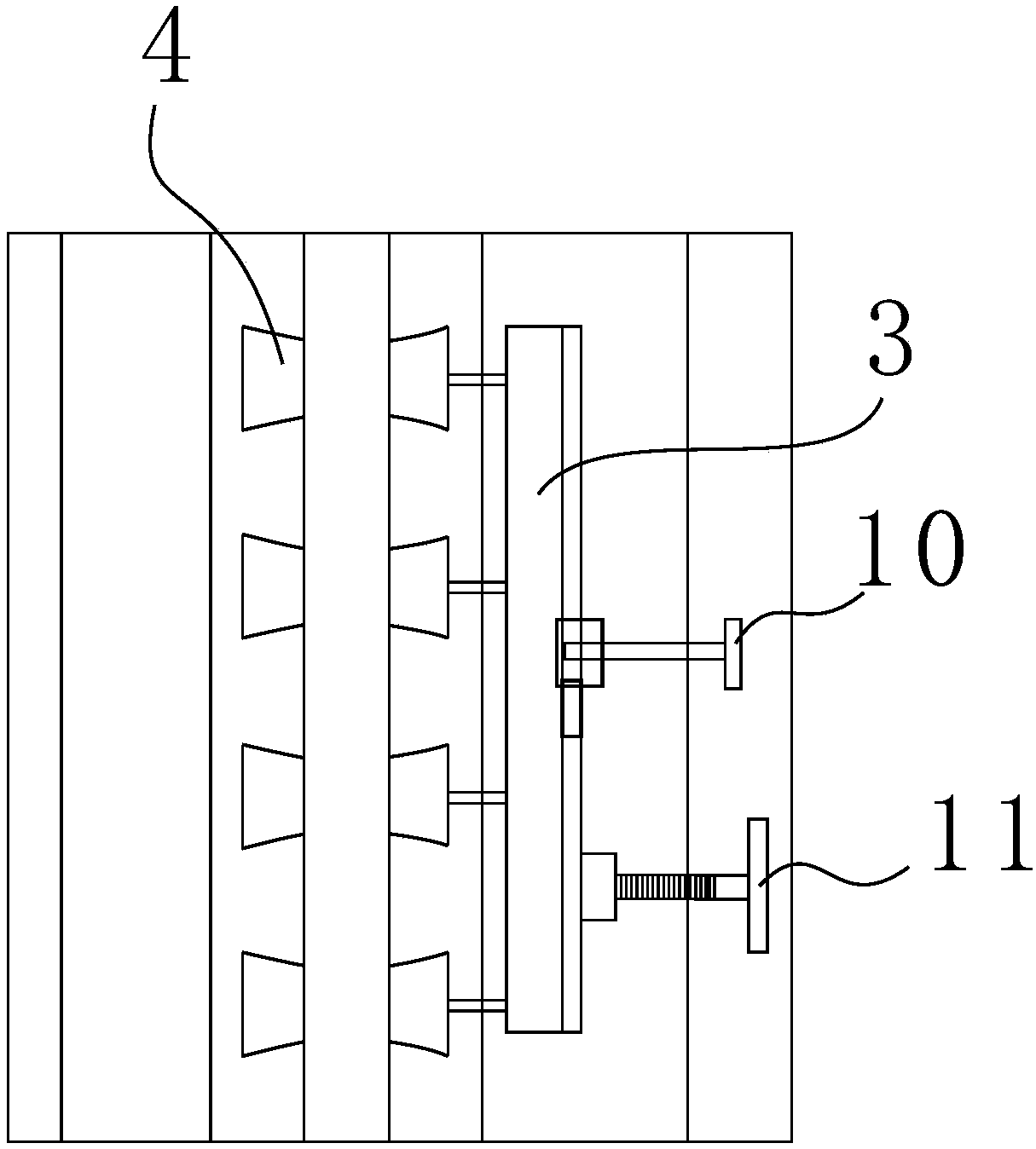

[0016] As shown in the figure, the present invention includes a base 1, a protective cover 2 arranged on the base, a pipe support adjustment mechanism and a cooling water circulation cooling device arranged on the base, and the pipe support adjustment mechanism includes a fixed frame 3 arranged side by side Set a plurality of guide support rollers 4 of the fixed frame, a lifting gear bar 5 located at the lower end of the fixed frame, a translation deck 6 located at the lower end of the lifting gear bar, a lifting gear located on one side of the lifting gear bar and engaged with the lifting gear bar 7 and the distance-adjusting lead screw 8 located on one side of the translation deck, the fixed mount is provided with a plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com