Biomass briquetting machine and biomass briquetting process

A biomass and briquetting machine technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of poor strength of biomass briquetting products, high cost of biomass briquetting machines, machine failures, etc. Achieve the effects of easy transportation and storage, simple structure, and reduced machine failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

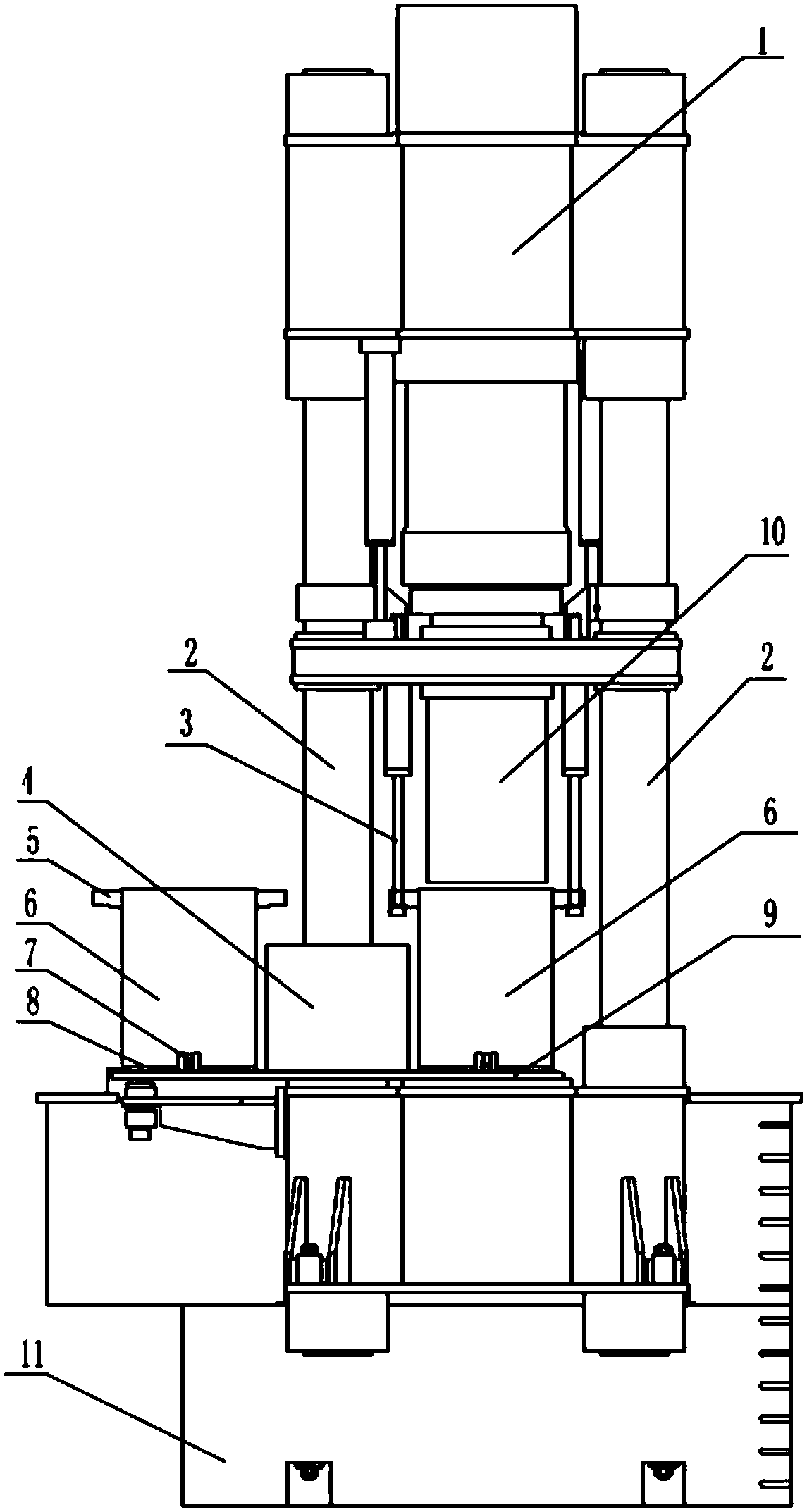

[0033] This embodiment provides a biomass briquetting machine, such as figure 1 As shown, it includes: a loading device, a briquetting device, and at least one feeding device; the feeding device is located above the loading device, and the loading device sends the loaded feeding device to the briquetting device through rotation. Biomass briquettes.

[0034] specific,

[0035] The loading device includes: a rotary table 9 arranged on the base 11, a drive shaft 4 arranged at the rotation center of the rotary table 9 for driving the rotation of the rotary table 9, and the drive shaft 4 is coaxial with the support column 2 of the briquetting device set up.

[0036] The feeding device includes: a mold sleeve 6 and a briquetting baffle 8 arranged at the bottom of the mold sleeve 6, the mold sleeve 6 and the briquetting baffle 8 form a hollow cylinder with an open top; the outer wall of the mold sleeve 6 is provided with a useful The sleeve lifting hole 5 used to lift the mold sle...

Embodiment 2

[0043] This embodiment provides a method for preparing biomass briquettes using the biomass briquetting machine described in Embodiment 1, comprising the following steps:

[0044] S1. Load the dried biomass with a moisture content of 8% to 20% and a temperature of 25° C. to 100° C. into the mold sleeve 6 on the rotary table 9 . As an embodiment of the present invention, in this embodiment, the moisture content of the biomass block is 15%, and the temperature is 60°C.

[0045] S2. The rotary table 9 is rotated, and the mold sleeve 6 containing the biomass material is sent to the position of the pressing part 10 for stamping, the pressure is 5Mpa-40Mpa, and the pressing speed is 0.1t / h-2t / h; After the specified pressure is reached and the stroke of the pressurizing part 10 remains unchanged, the pressure is maintained for 10s-60s. As an embodiment of the present invention, in this embodiment, the stamping pressure is 20 MPa, the pressing speed is 1 t / h, and the holding time is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com