Overturning device for uprightly arranging prefabricated laminated slab and operation method thereof

A flipping device and laminated board technology, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of non-turnable work, breakage and damage at the bottom of components, and high difficulty, with low proficiency requirements and good storage performance , high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

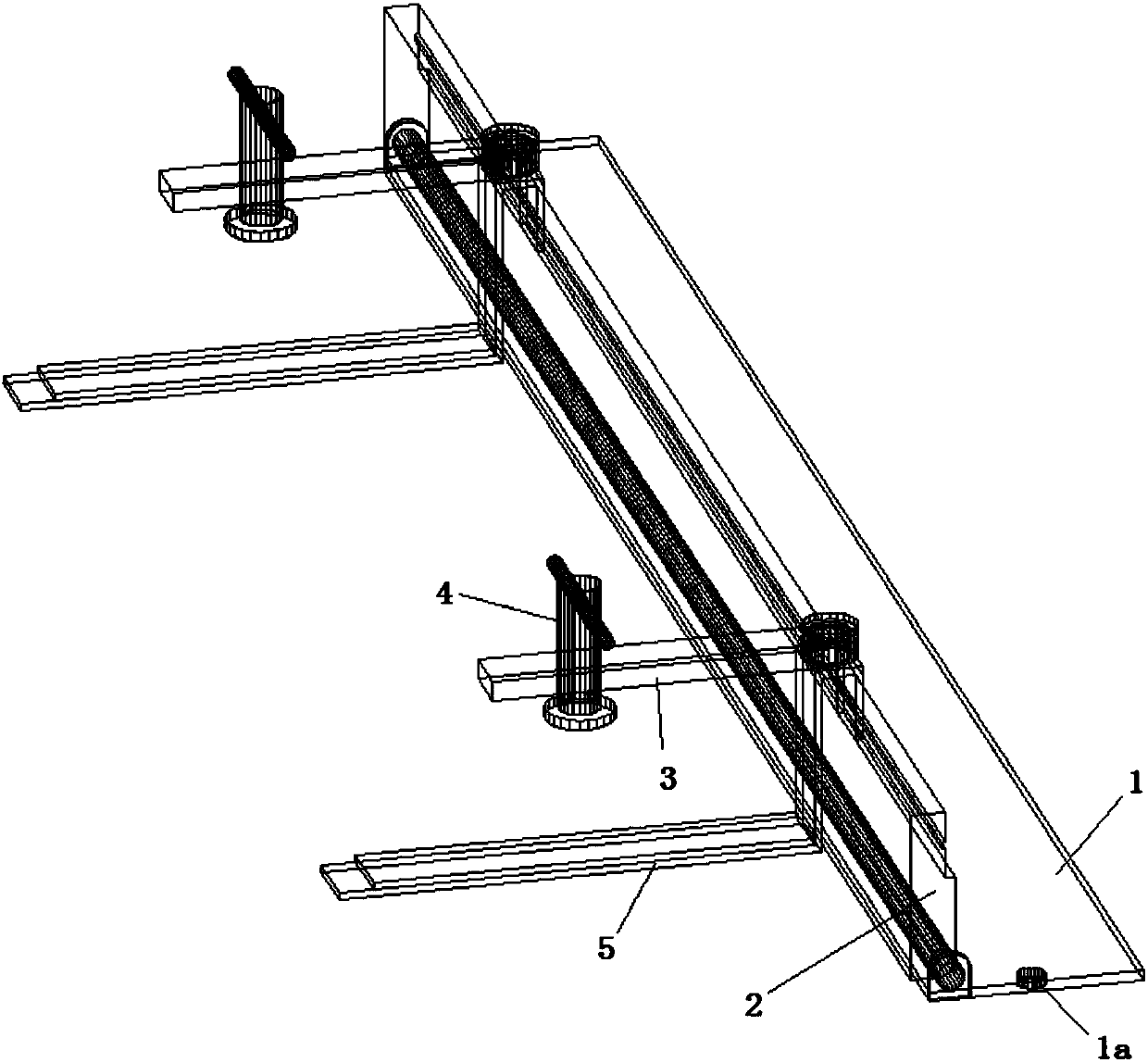

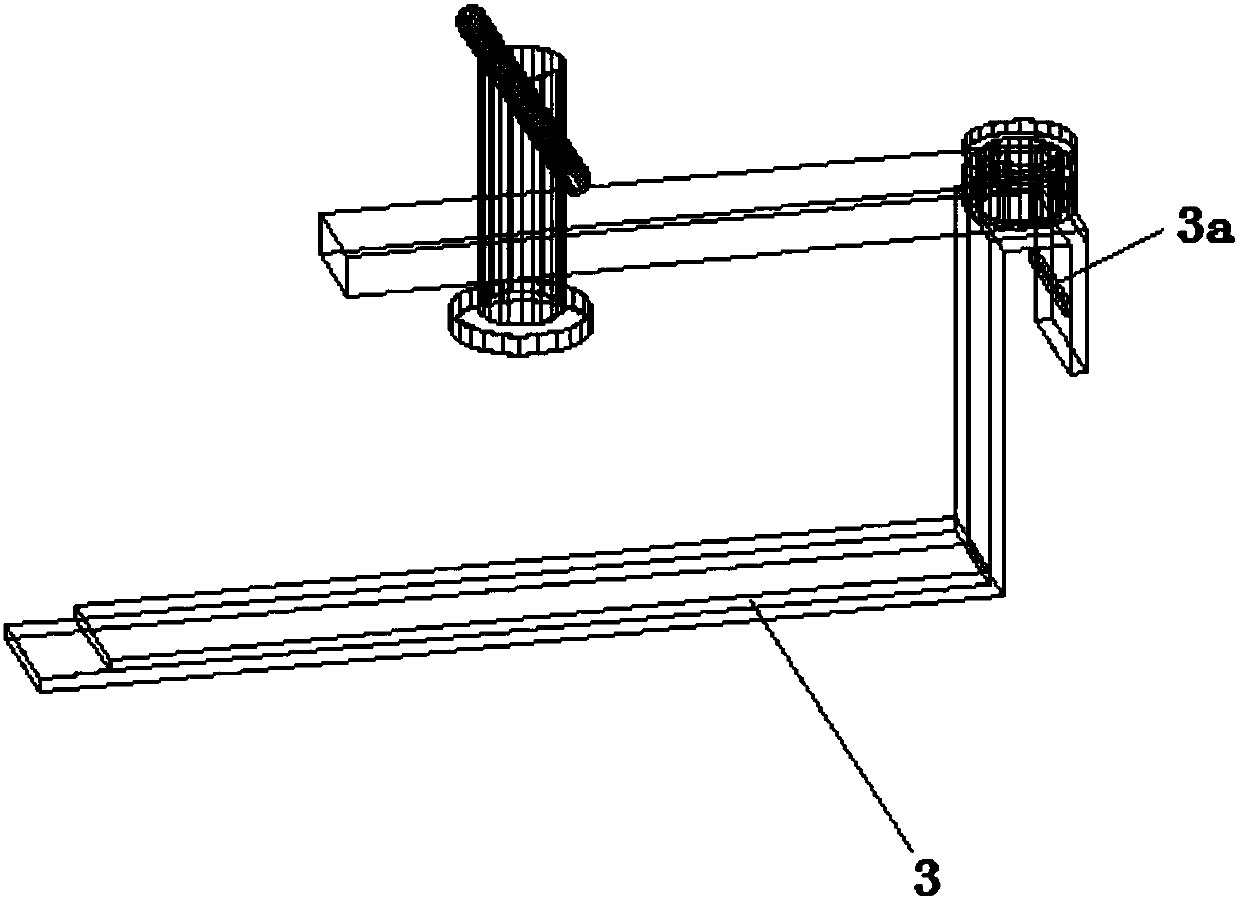

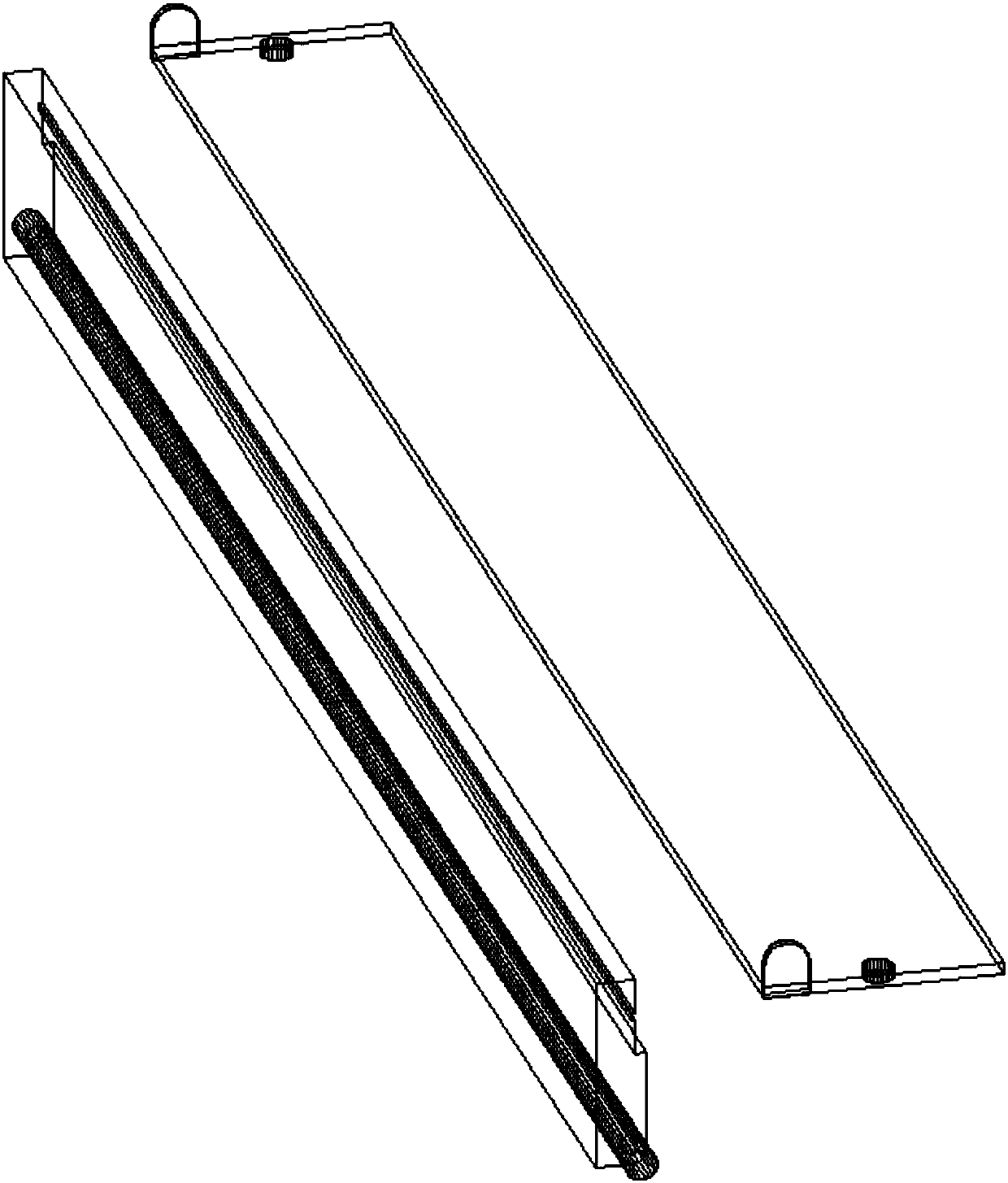

[0048] see Figure 1-Figure 15 , an upright prefabricated laminated board turnover device, including a fixed base plate 1, a flip plate 2, a sliding fixing member 5, a rotating fixing member 3, and a pressing mechanism 4; Positioning hole 1a; one side of the flip plate 2 is rotationally connected with the fixed base plate 1, and a plurality of sliding fixtures 5 that can slide along it are arranged on the other side, and the upper end of the sliding fixture 5 is rotationally connected with the rotating fixture 3. The rotating fixing part 3 is provided with a pressing mechanism 4, and the pressing mechanism 4 and the sliding fixing part 5 clamp and fix the prefabricated laminated board.

[0049] In this embodiment, the back of the turnover plate 2 is provided with a guide notch 2b along the direction of the rotation axis, and the guide notch 2b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com