A kind of viaduct pier beam and its construction technology

A technology for viaduct piers and beams, which is applied in the field of preparation process of viaduct pier beams, which can solve the problems of long-term road closures, numerous procedures, and long construction periods, and achieve long construction periods, increased bending and compression resistance, and smooth construction. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

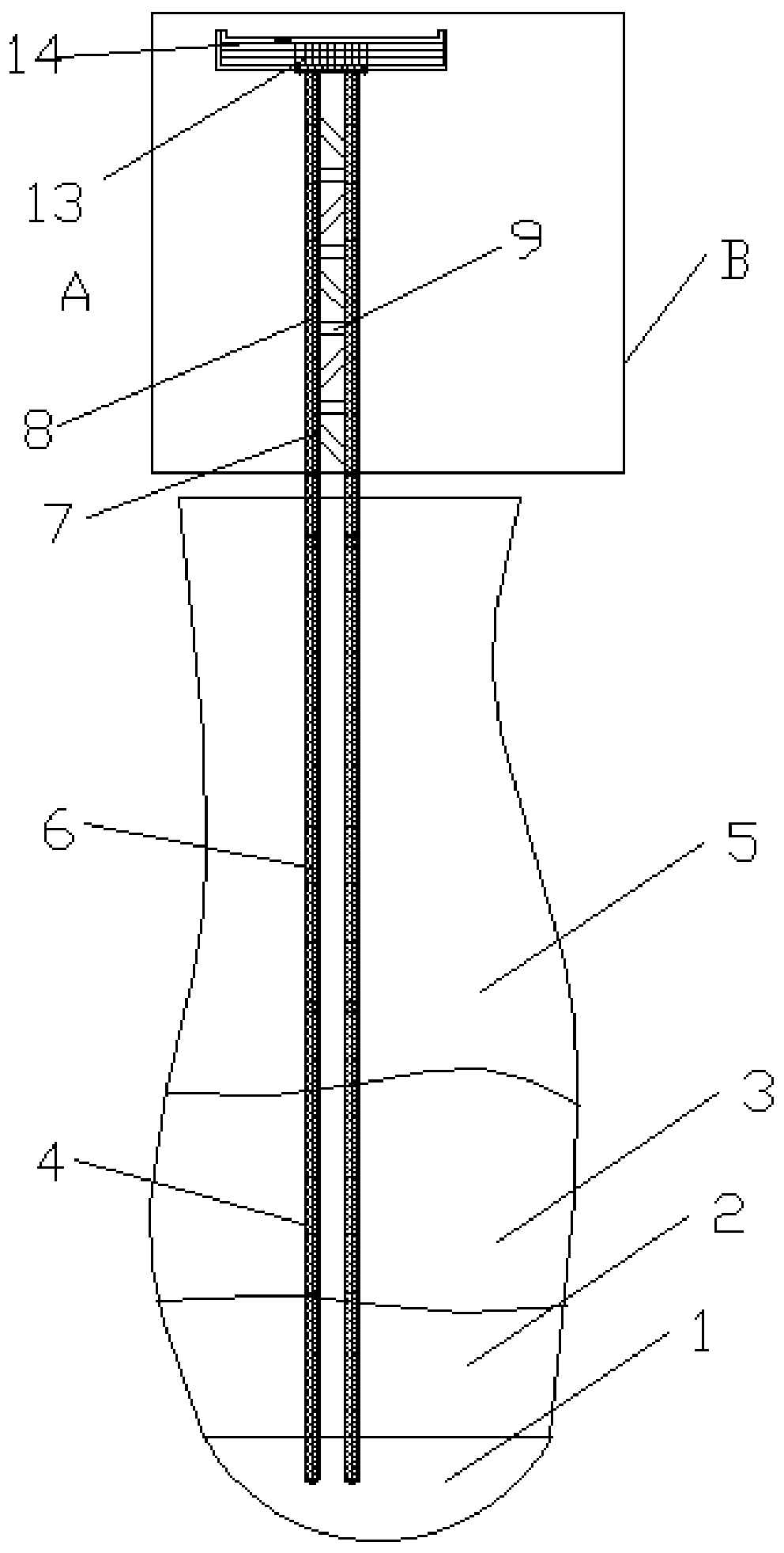

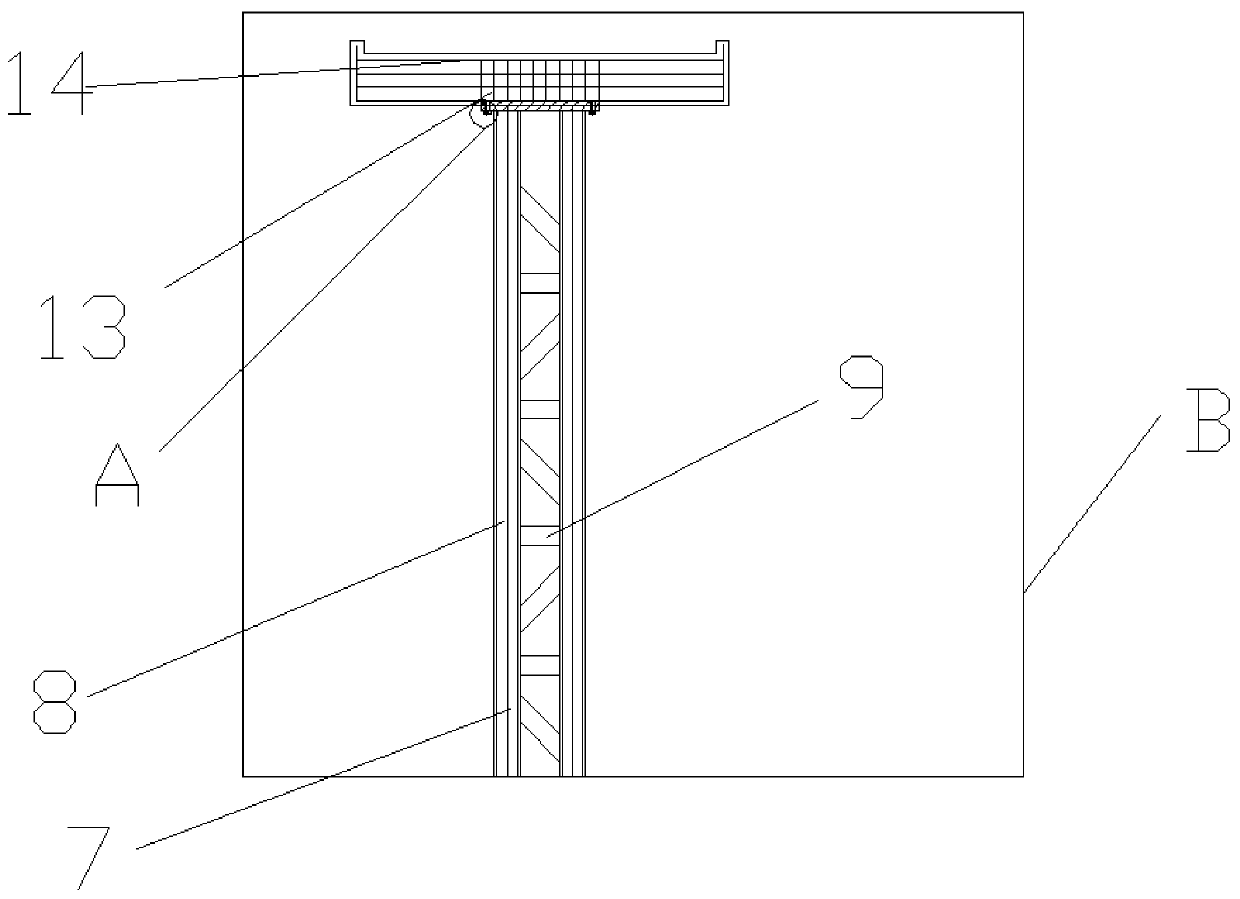

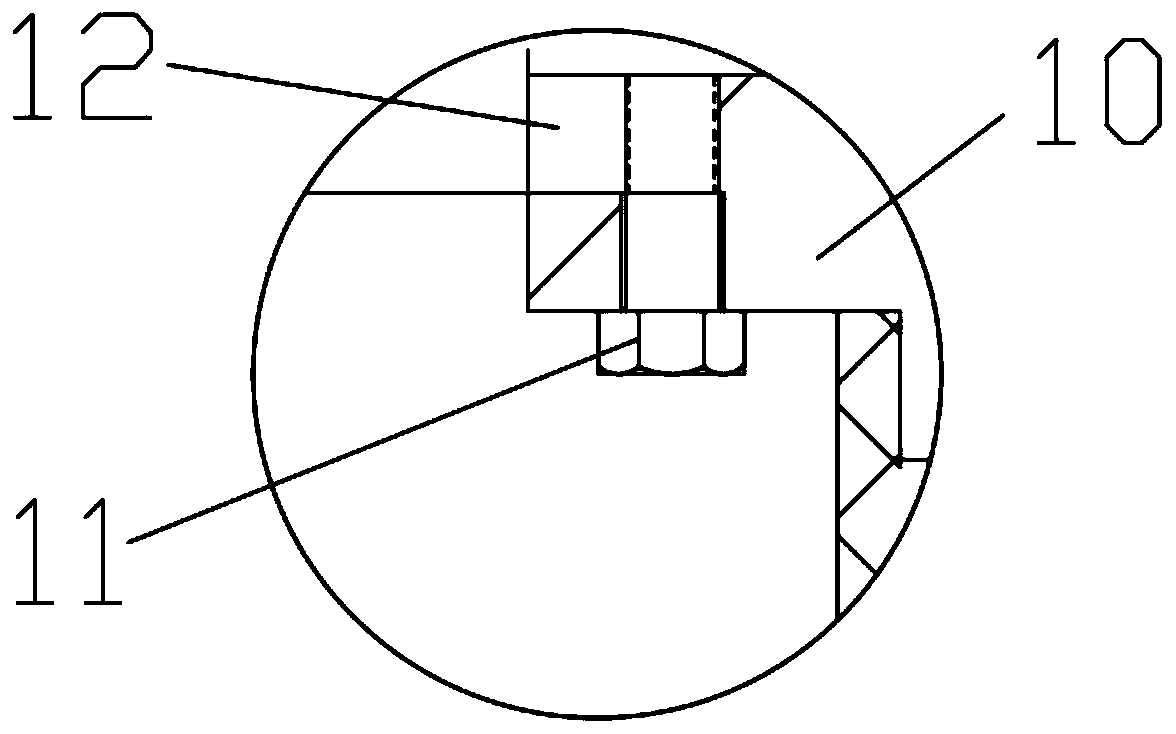

[0033] Embodiment 1:, a bridge pier crossbeam of viaduct, comprises crossbeam 14 and several pier piers, is characterized in that: said pier is made up of a terminal pipe 4, several middle-end pipes 6 and a top pipe 7, and said end The pipe 4, the middle pipe 6 and the top pipe 7 are injected with micro-expanded concrete 8, the middle part of the beam 14 is provided with a threaded steel cage 13, the top of the pier is provided with a pier connecting steel plate 10, and the bottom of the crossbeam 14 is provided with The crossbeam connecting steel plate 12 is fixed by connecting screws 11 between the crossbeam connecting steel plate 12 and the pier connecting steel plate 10, and the end pipe 4, the middle end pipe 6 and the top pipe 7 are all thick-walled steel pipes, and are connected by threads. The surface of the bridge pier adopts anti-corrosion treatment or anti-corrosion material, the surface of the pier connecting steel plate 10 and the beam connecting steel plate 12 ado...

Embodiment 2

[0035] An elevated bridge pier crossbeam, comprising a crossbeam 14 and several piers, is characterized in that: the pier is composed of a terminal pipe 4, several middle-end pipes 6 and a top pipe 7, the end pipe 4, the middle pipe Micro-expanded concrete 8 is injected into the pipe 6 and the top pipe 7, a threaded steel cage 13 is arranged in the middle of the crossbeam 14, a pier connecting steel plate 10 is arranged on the top of the pier, and a crossbeam connecting steel plate 12 is arranged on the bottom of the crossbeam 14, The beam connecting steel plate 12 and the bridge pier connecting steel plate 10 are fixed by connecting screws 11, the surface of the bridge pier adopts anti-corrosion treatment or adopts corrosion-resistant materials, and the end pipe 4, the middle end pipe (6) and the top end pipe 7 are all Thick-walled steel pipes are welded to each other. The bottom of the end pipe 4 is pointed or convex. The surface of the connecting steel plate 10 for the pier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com