Composite wind power generation device based on reverse electrowetting and electromagnetic induction

A wind power generation device, electromagnetic induction technology, applied in the direction of wind power generation, wind engine, wind motor combination, etc., can solve the problem of mechanical energy conversion that has not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

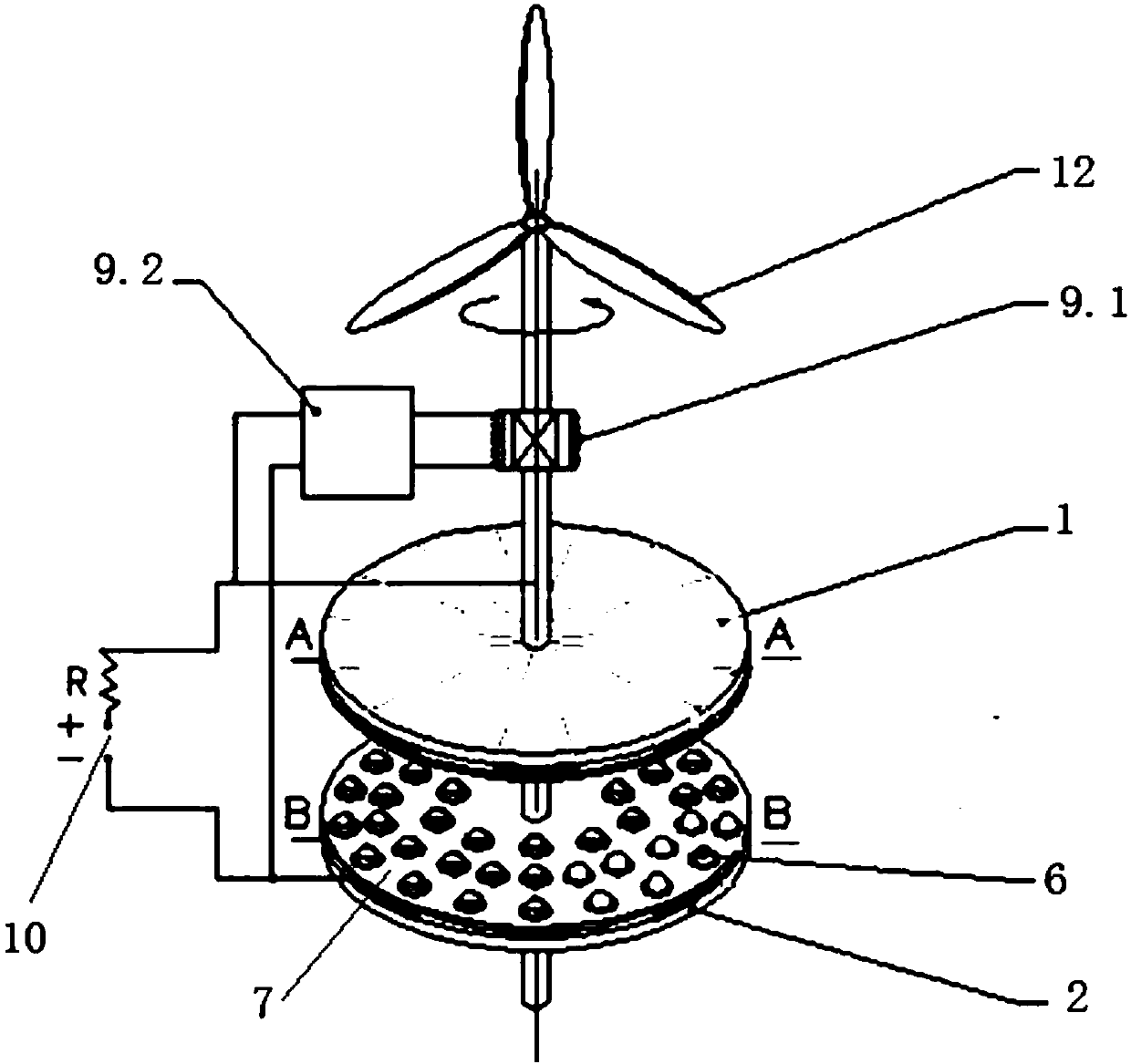

[0031] Attached below Figure 1-7 The present invention is described further:

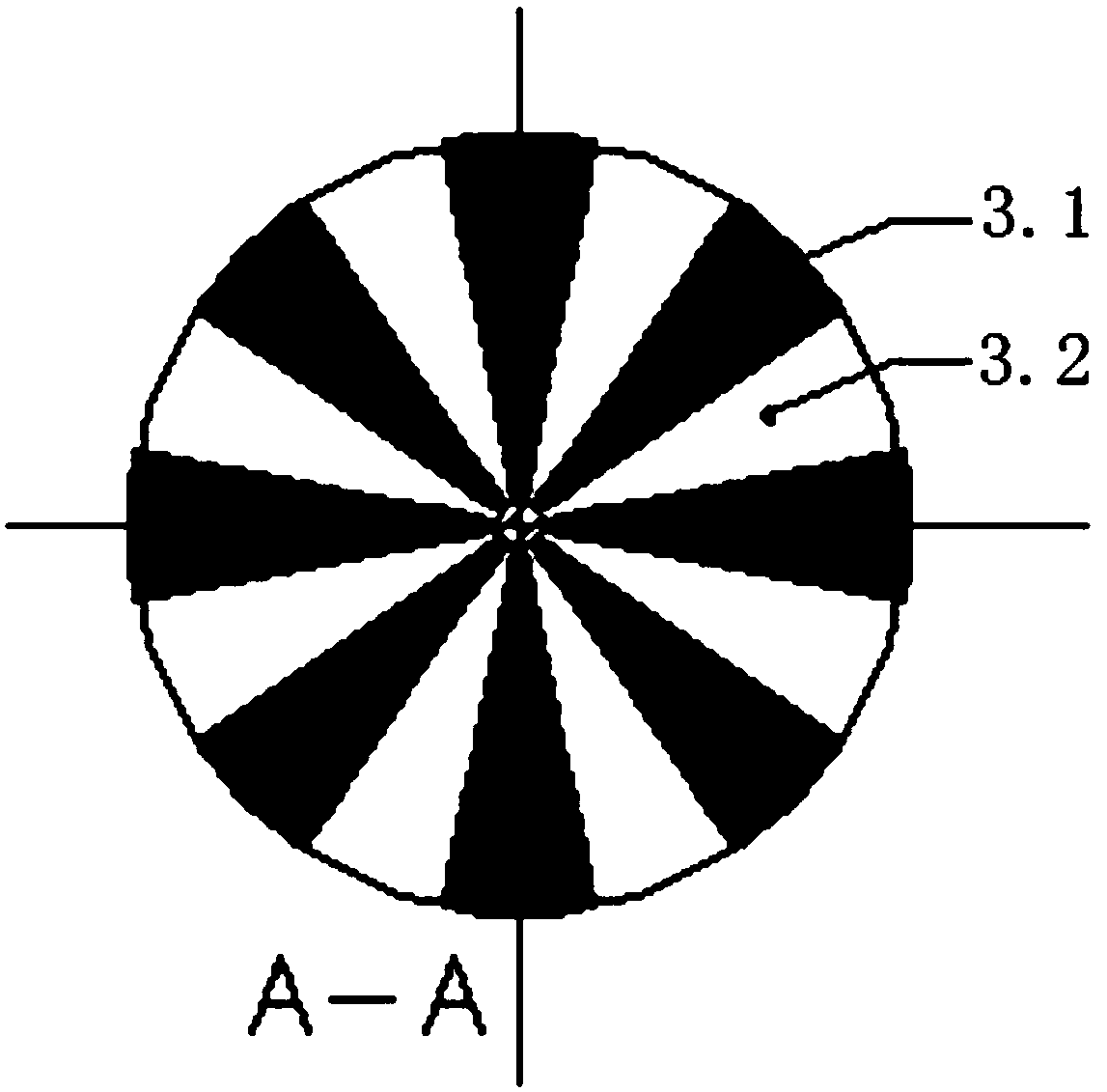

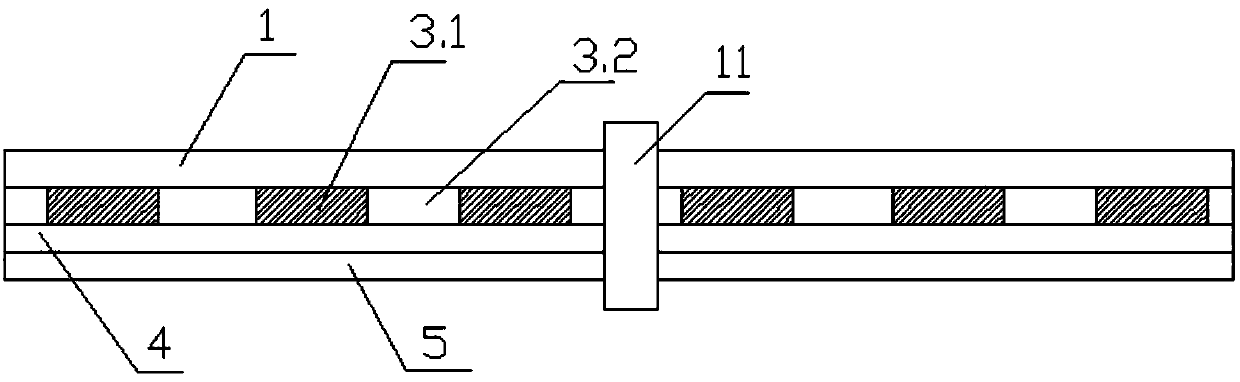

[0032] A composite wind power generation device based on reverse electrowetting and electromagnetic induction, including an upper base plate 1 and a lower base plate 2 arranged parallel to each other, a central axis 11 connects the upper base plate 1 and the lower base plate 2, and a permanent magnet generator 9.1 is located on the central axis 11 and connected to the central shaft 11 in rotation, the top of the central shaft 11 is connected to the fan blade 12, and the fan blade 12 drives the central shaft 11 and the upper base plate 1 to rotate relative to the fixed lower base plate 2 and the permanent magnet generator 9.1 under the action of the wind force. The lower surface of the upper substrate 1 is sequentially provided with a first electrode layer, the first dielectric layer 4 and the low surface energy material layer 5, and the upper surface of the lower substrate 2 is sequentially provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com