Blade deicing control method and device and deicing system for wind driven generator

A technology of wind power generator and control method, which is applied in the field of deicing system and blade deicing control, and can solve the problems of large heating energy loss and poor deicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0127] The invention provides a blade deicing control method of a wind power generator to solve the problems of excessive heating energy loss and poor deicing effect in the prior art.

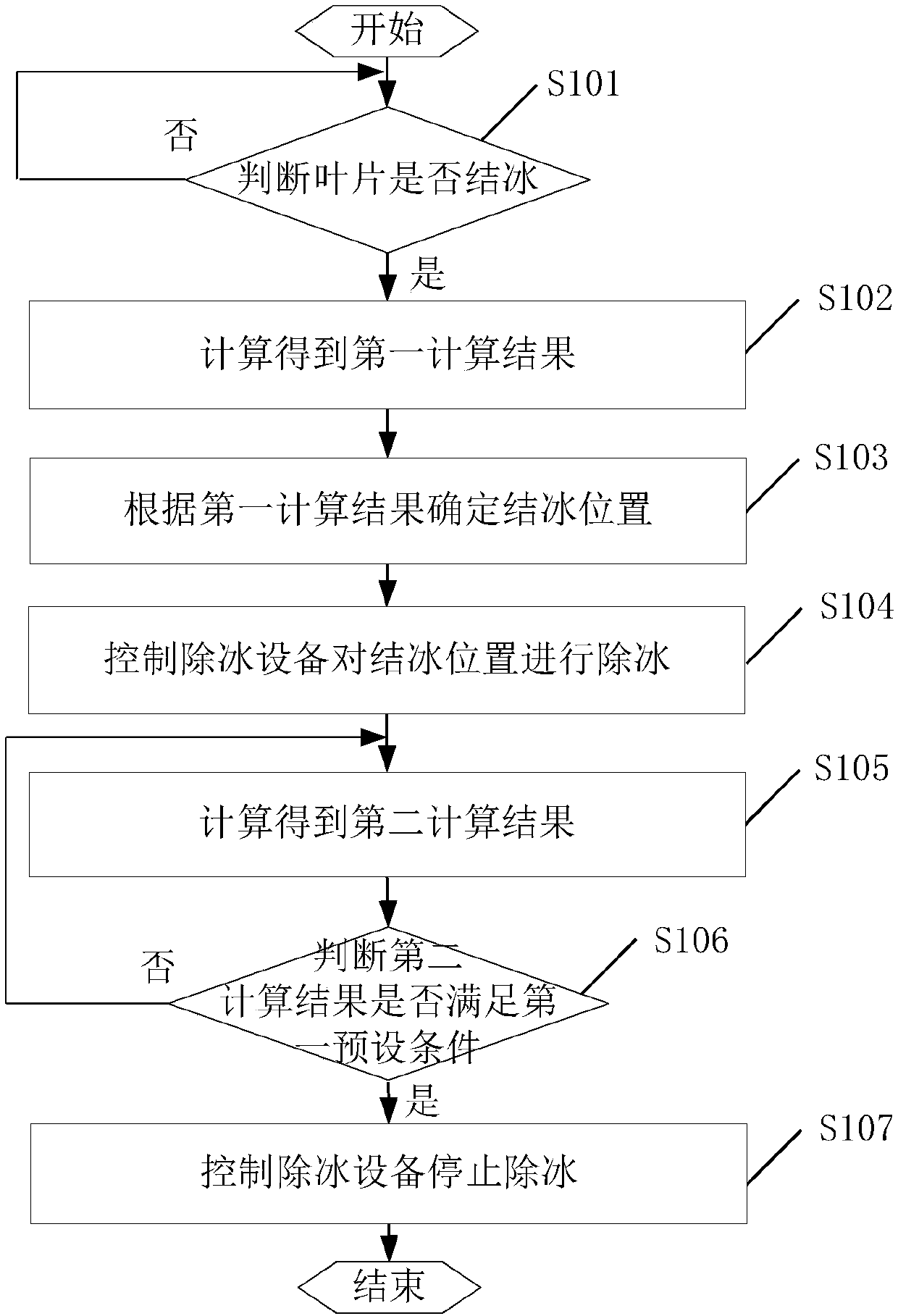

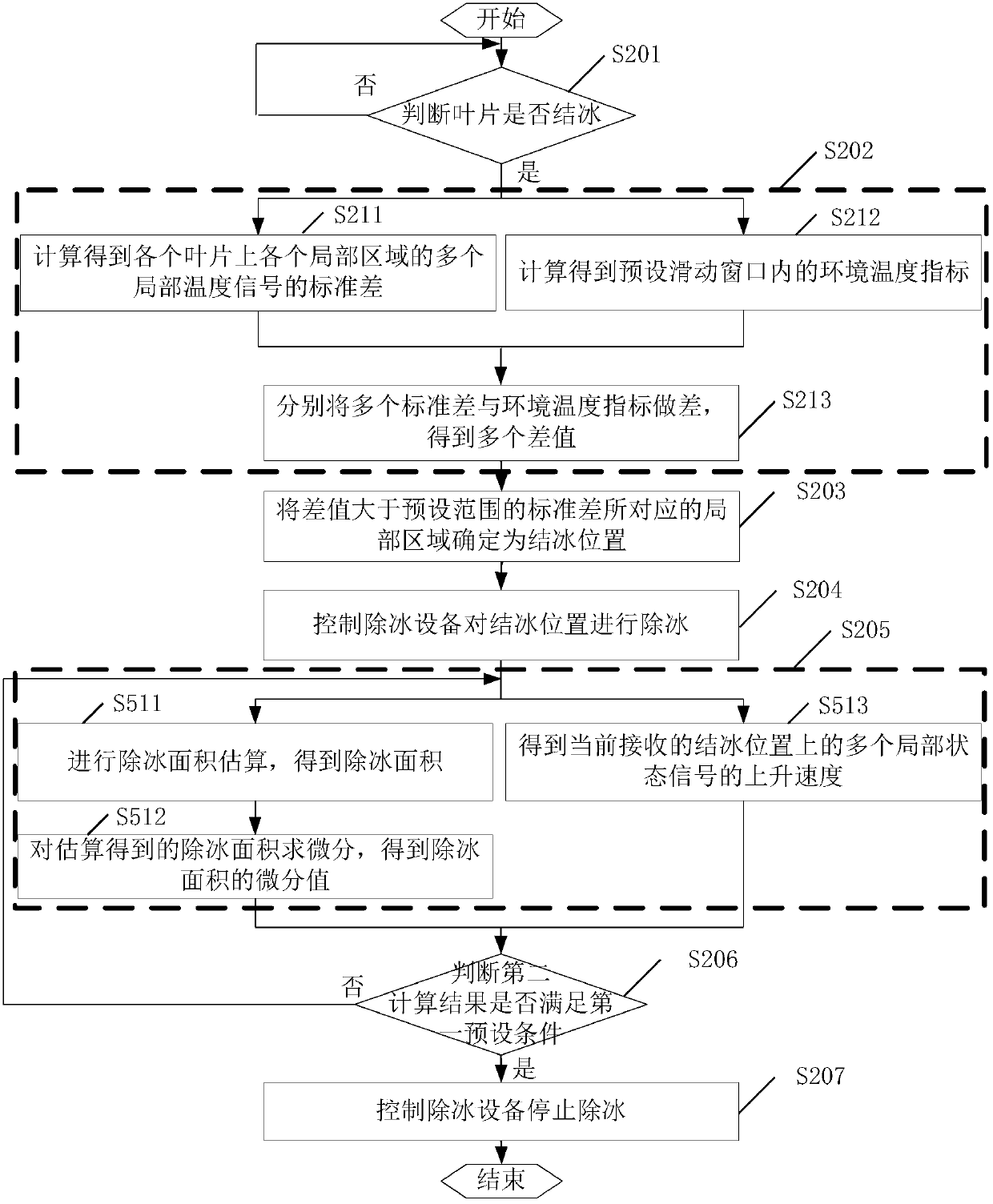

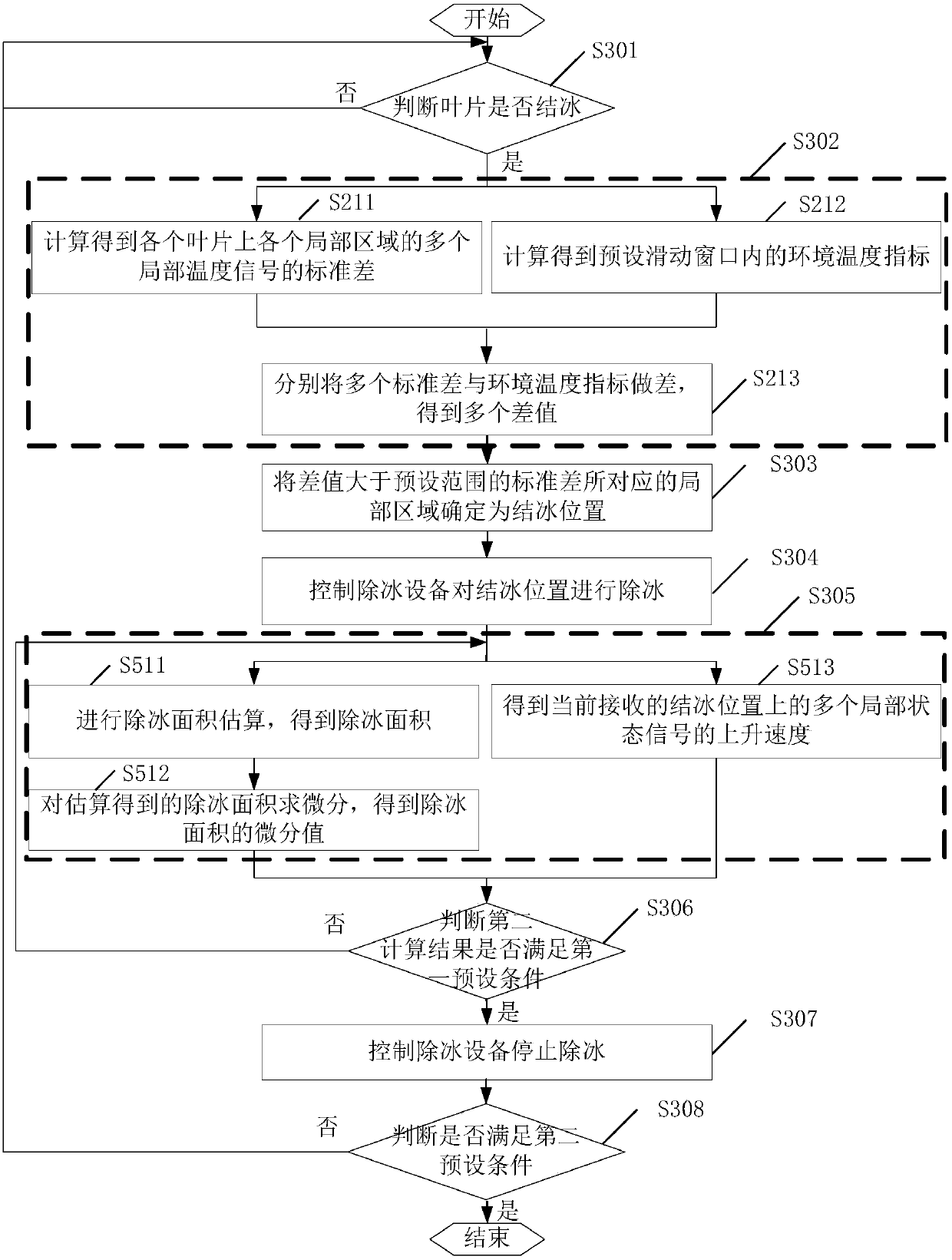

[0128] Specifically, the blade deicing control method of the wind power generator, such as figure 1 As shown, the control method includes the following steps.

[0129] S101: Determine whether the blade is frozen.

[0130] The specific manner may include judging the received corresponding information (such as icing or not icing), or analyzing the received icing detection data before making the judgment, which is not specifically limited here.

[0131] If it is judged that the blade is icy, step S102 is performed to calculate the currently received refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com