Method for purifying shikimic acid in Chinese star anise

A purification method, shikimic acid technology, applied in the field of shikimic acid purification, can solve the problems of high cost, high loss of shikimic acid, cumbersome and time-consuming operation, etc., achieve high recovery rate, avoid excessive loss, and reduce operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

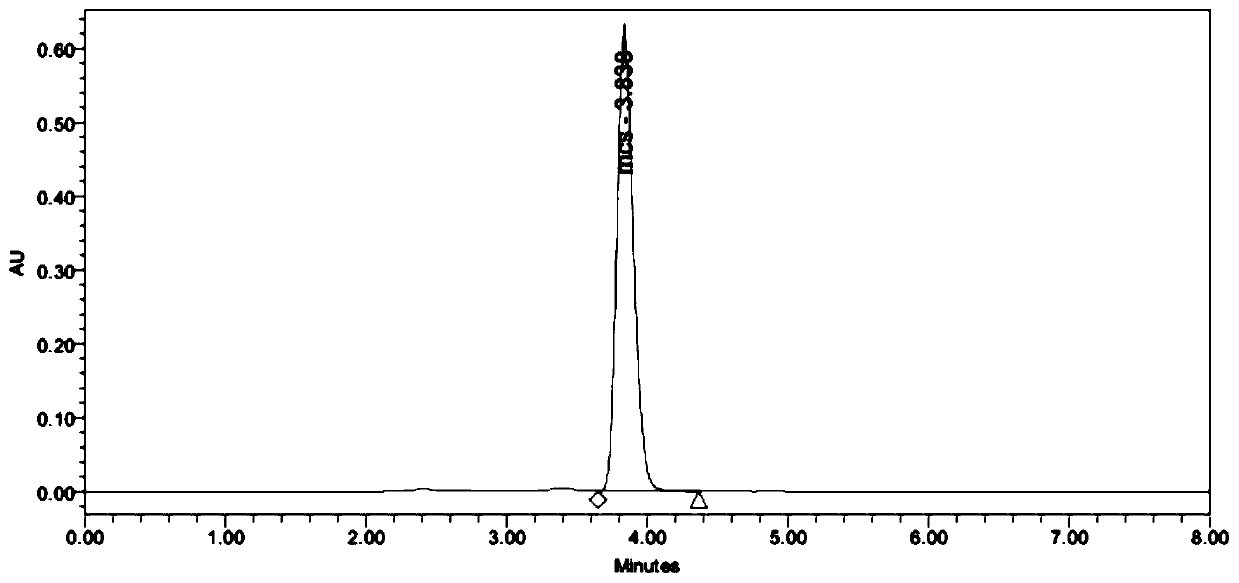

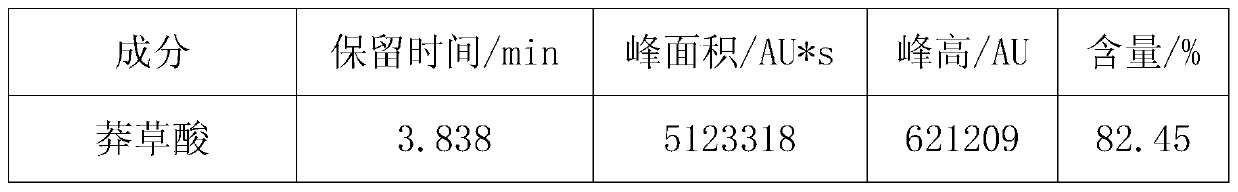

Image

Examples

Embodiment 1

[0040] 1) extract

[0041] Crush and sieve the fresh star anise raw material, the mesh size of the sieve is 60 mesh; add water-saturated n-butanol, heat and stir for extraction, a total of 3 extractions, and the water-saturated n-butanol used for each extraction is 8 times the quality of the star anise raw material Quantity, extraction time is 2h, extraction temperature is 80 ℃, extracts are combined and suction filtered to obtain star anise extract;

[0042] 2) Purification

[0043] The star anise extract obtained in step 1) was concentrated under reduced pressure for the first time under the conditions of a vacuum of -0.08Mpa and a temperature of 80°C to obtain a first concentrate with a specific gravity of 1.05; the first concentrate was heated at 25°C Leave to crystallize for 24 hours, and filter with suction to remove oily precipitates and impurity crystals to obtain the first filtrate and precipitate A;

[0044]The precipitate A was rinsed with saturated n-butanol, com...

Embodiment 2

[0049] 1) extract

[0050] Crush and sieve the fresh star anise raw material, the mesh size of the sieve is 40 mesh; add water-saturated n-butanol, heat and stir for extraction, a total of 2 extractions, the water-saturated n-butanol used for each extraction is 6 times the quality of the star anise raw material Quantity, extraction time is 1.5h, extraction temperature is 70 ℃, the extracts are combined and suction filtered to obtain star anise extract;

[0051] 2) Purification

[0052] The star anise extract obtained in step 1) was concentrated under reduced pressure for the first time under the conditions of a vacuum of -0.08MPa and a temperature of 75°C to obtain a first concentrate with a specific gravity of 1.01; the first concentrate was heated at 20°C Leave to crystallize for 18 hours, and filter with suction to remove oily precipitates and impurity crystals to obtain the first filtrate and precipitate A;

[0053] The precipitate A was rinsed with saturated n-butanol, ...

Embodiment 3

[0058] 1) extract

[0059] Crush and sieve the fresh star anise raw material, the mesh size of the sieve is 80 mesh; add water-saturated n-butanol, heat and stir for extraction, a total of 4 extractions, and the water-saturated n-butanol used for each extraction is 10 times the quality of the star anise raw material Quantity, extraction time is 3h, extraction temperature is 90 ℃, the extracts are combined and suction filtered to obtain star anise extract;

[0060] 2) Purification

[0061] The star anise extract obtained in step 1) was concentrated under reduced pressure for the first time under the conditions of a vacuum of -0.07Mpa and a temperature of 85°C to obtain a first concentrate with a specific gravity of 1.1; the first concentrate was heated at 30°C Leave to crystallize for 26 hours, and filter with suction to remove oily precipitates and impurity crystals to obtain the first filtrate and precipitate A;

[0062] The precipitate A was rinsed with saturated n-butanol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com