A drive shaft support assembly for a vehicle

A transmission shaft and component technology, applied in the field of vehicle transmission shaft support components, can solve the problems of poor vibration damping effect, load damage, easy fatigue damage of the transmission shaft, etc., and achieve the effects of long service life and good vibration reduction and isolation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

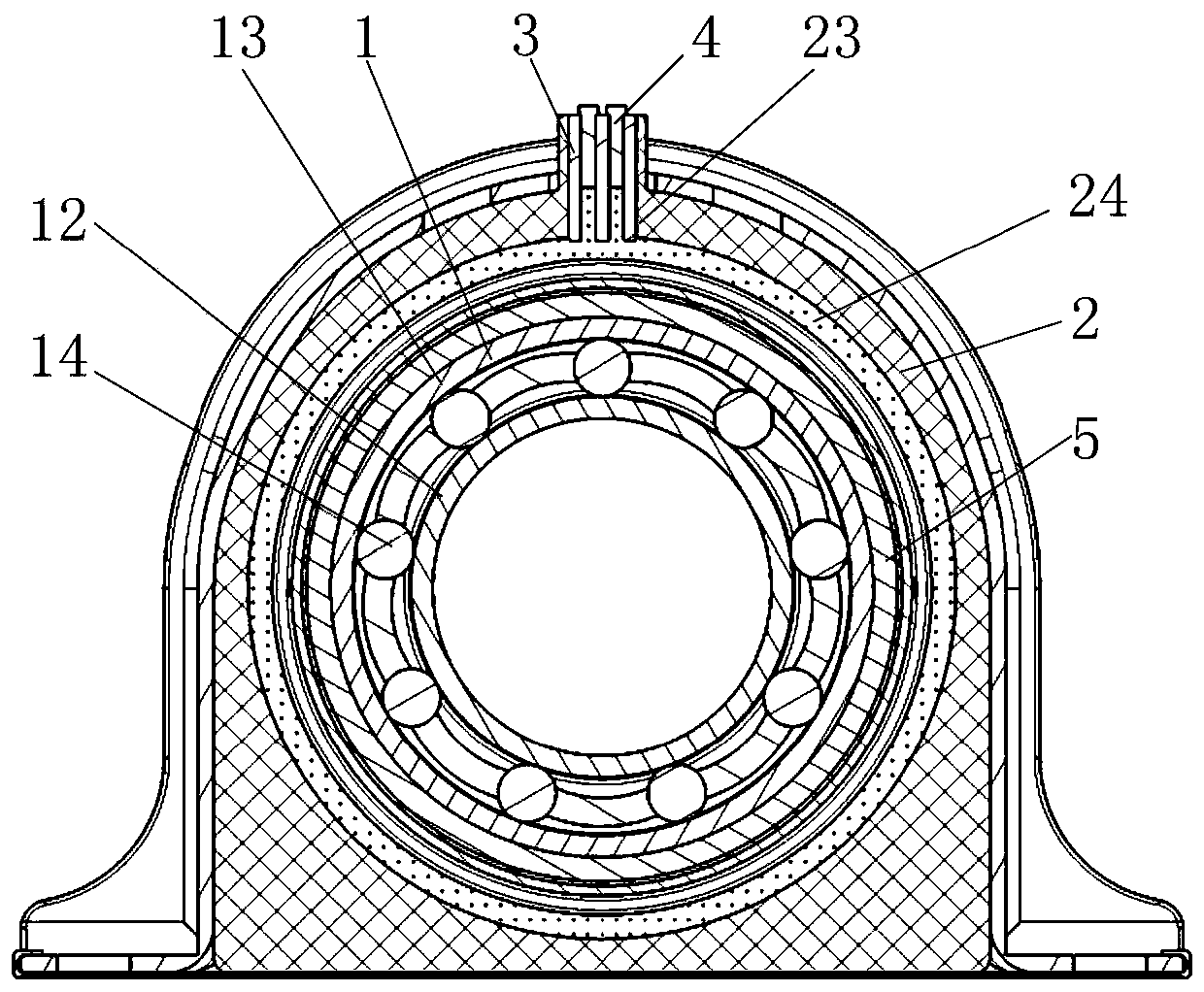

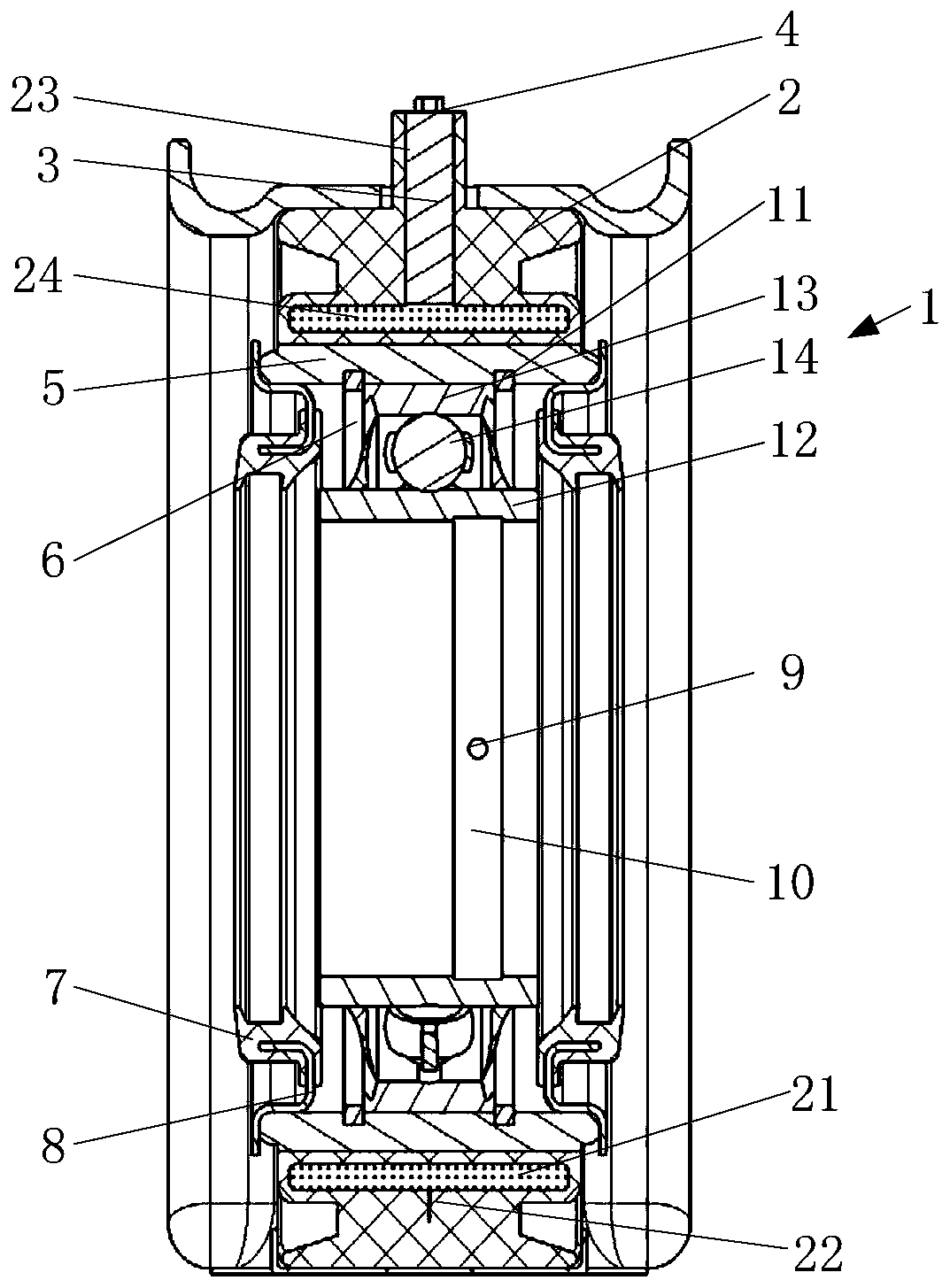

[0027] Such as figure 1 and figure 2 As shown, the transmission shaft support assembly for a vehicle in this embodiment includes a bearing 1 and an elastic body 2 sleeved on the bearing 1. The elastic body 2 is provided with a damping chamber 21. The damping chamber 21 is an annular chamber. The cavity 21 is filled with viscous silicone oil 24 . In the present invention, a damping chamber 21 is provided on the elastic body 2, and the damping chamber 21 is filled with viscous silicone oil 24, so that the bearing 1 not only has the function of supporting and isolating vibration when the transmission shaft vibrates, but also can reduce vibration through viscous damping, which breaks through The traditional pure rubber support has small damping and is not adjusta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com