Six-terminal network-type kilowatt-class radiofrequency power resistor

A radio frequency power, six-terminal network technology, applied in resistors, non-adjustable metal resistors, resistor cooling/heating/ventilation devices, etc., can solve the problems of the central temperature rise of the resistor body, inability to solve heat dissipation, large parasitic parameters, etc. , to increase the ability to withstand power, reduce the overall distribution parameters, and improve the frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

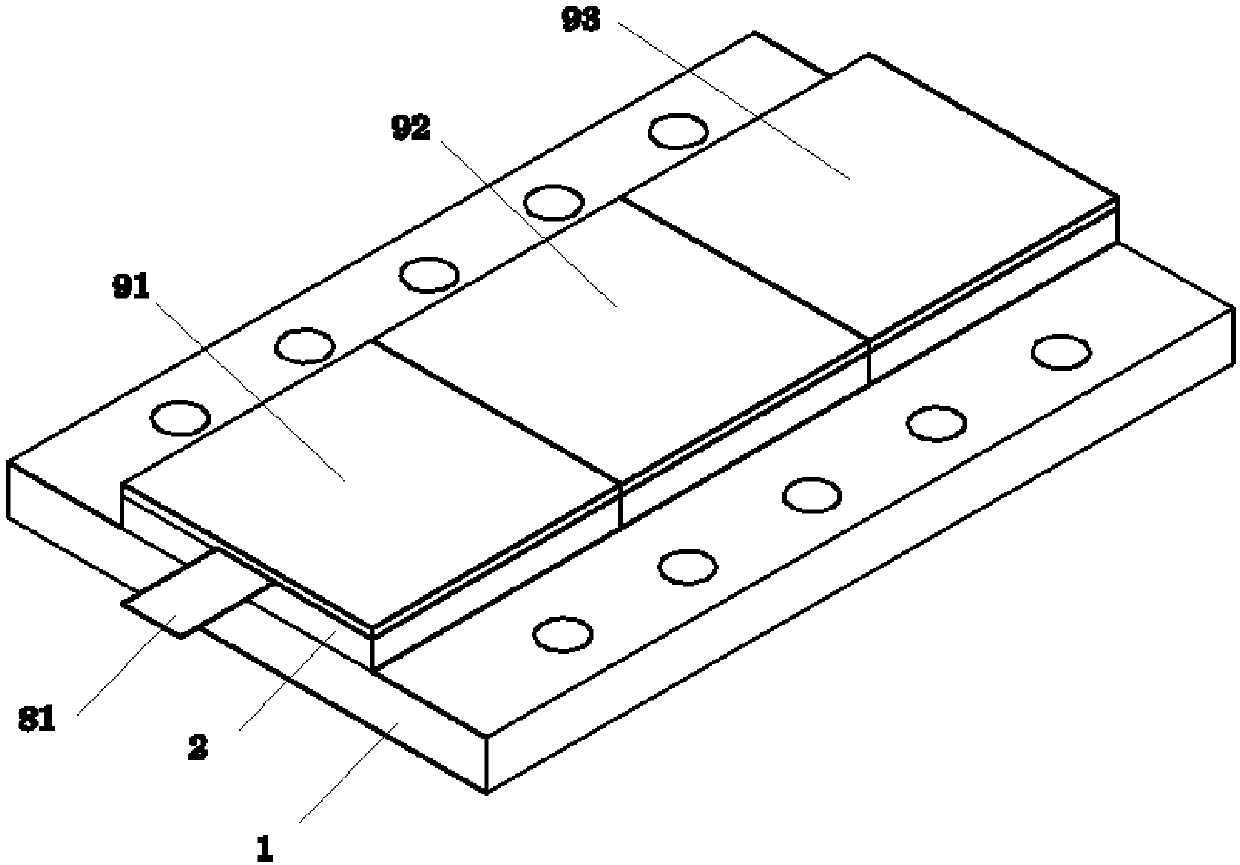

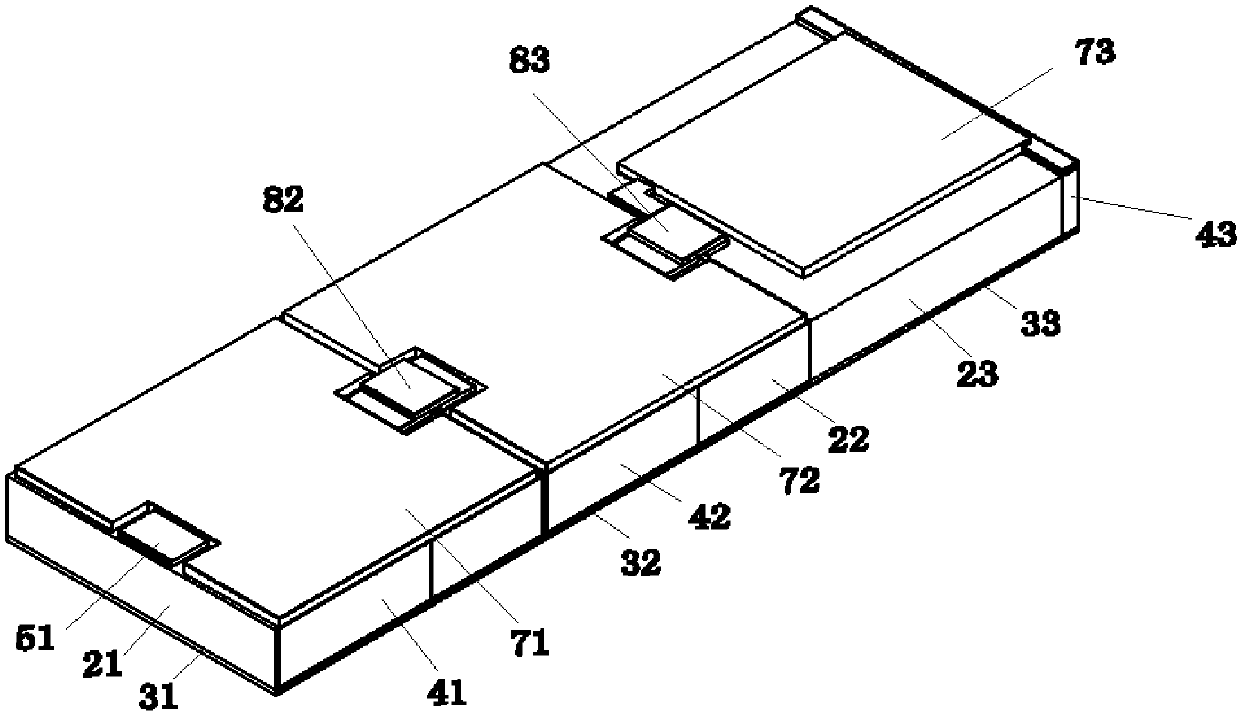

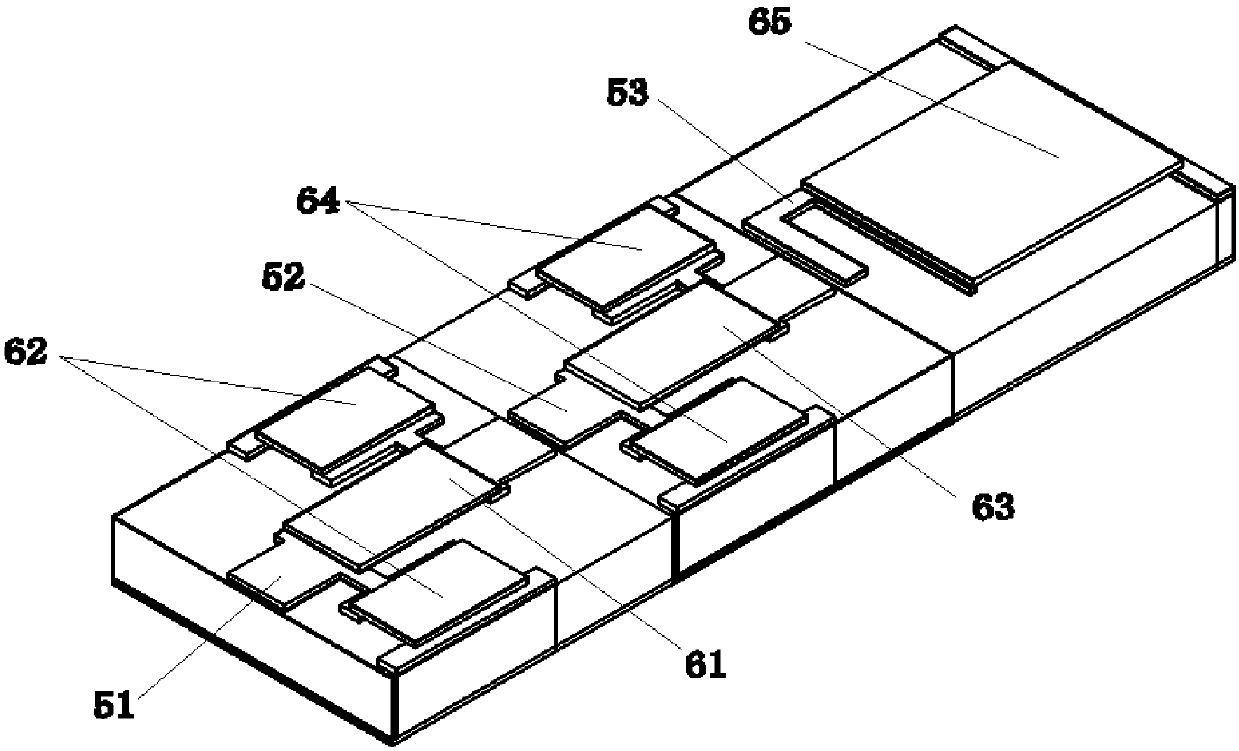

[0016] Example: see figure 1 , figure 2 with image 3 , a six-terminal network type kilowatt-level radio frequency power resistor, including a flange 1 and a base 2, the resistor system is composed of three systems: a primary attenuation system, a secondary attenuation system and a load system; the primary attenuation system The two-stage attenuation system adopts a π-shaped attenuation structure, which includes three substrates 2 and respective A-surface electrodes 5, B-surface electrodes 3, and side electrodes 4;

[0017] The A surface electrode 5 is on the upper surface of the substrate 2, the A surface electrode 5 of the primary attenuation system and the secondary attenuation system is an attenuation electrode, and the load system is a load electrode, and the attenuation electrode is composed of two parts that are centrally symmetrical. Composition, the load electrode is a reverse "匚" shape structure; the B surface electrode 3 is on the lower surface of the substrate 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com