High-torque high-rotating-speed serially excited motor

A high-speed, high-torque technology, used in electrical components, electromechanical devices, electric components, etc., can solve the problems of large jitter, high cost, complex structure, etc., to meet the speed requirements, large starting torque, wide range of speed regulation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

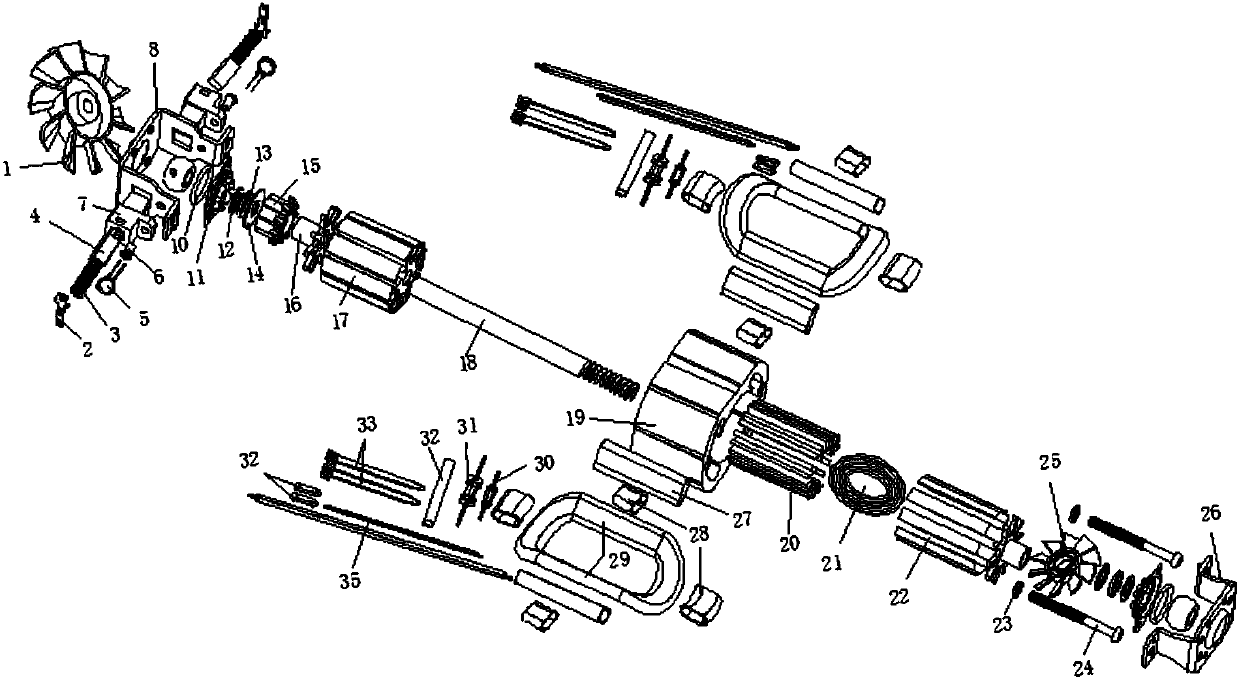

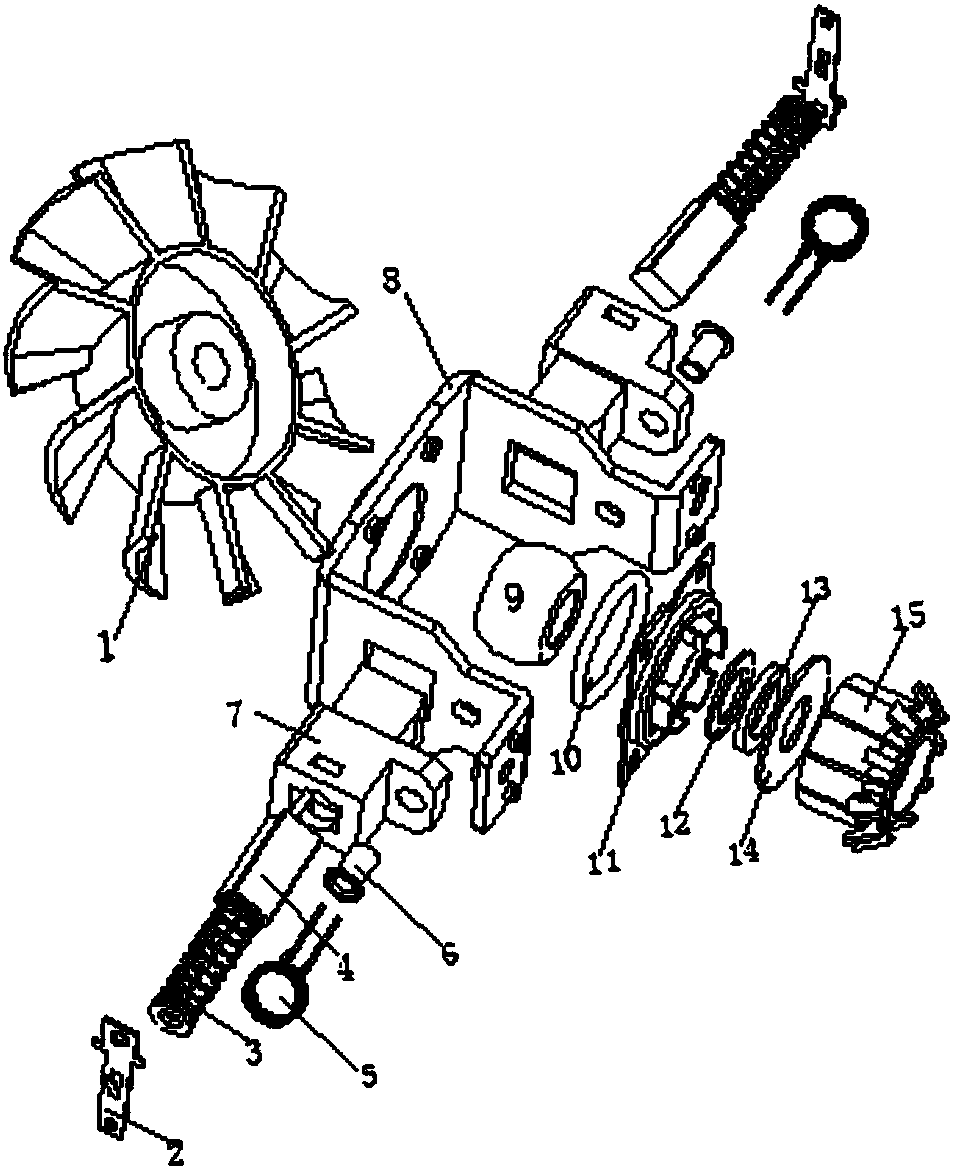

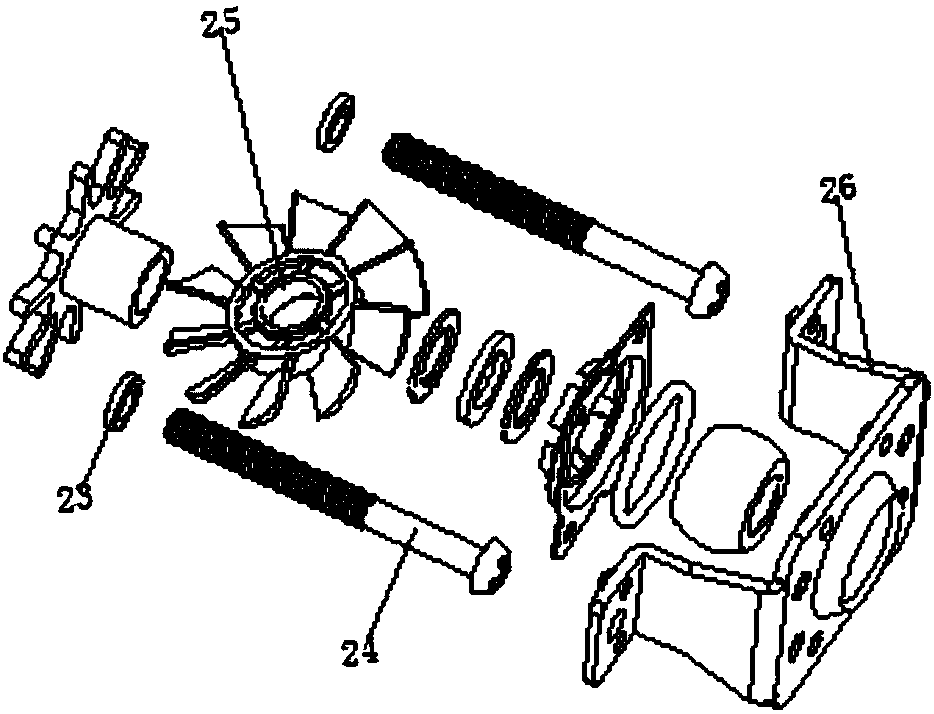

[0014] The present invention as figure 1 , 2 As shown, a high-torque and high-speed series-excited motor includes a rotor 18 whose two ends are respectively connected to the front bracket 26 and the rear bracket 8 through ball bearings 9, and a stator with a stator insulating slot paper 20 inside and sleeved on the rotor. Iron core 19, the rotor is provided with a rotor core 17, the stator core is provided with a stator coil 21, the rear end of the rotor is provided with a rear fan 1 located outside the rear bracket; the rear bracket is provided with a commutator 15. There are O-rings 10, mounting bases 11, plastic gaskets 12, wave gaskets 13, and spacers 14 between the rear bracket and the commutator; carbon brushes corresponding to the commutator are provided on the rear bracket 4. The carbon brush is fixed on the carbon brush cover 7 through the copper sleeve 6, and the carbon brush cover is fixed on the side wall of the rear bracket through rivets. The side wall of the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com