Catalyst for ethoxylation of fatty acid methyl esters

A fatty acid methyl ester and ethoxylation technology, which is applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, catalytic reactions, etc., can solve the problem of less by-products, narrow EO distribution, and Waiting for questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

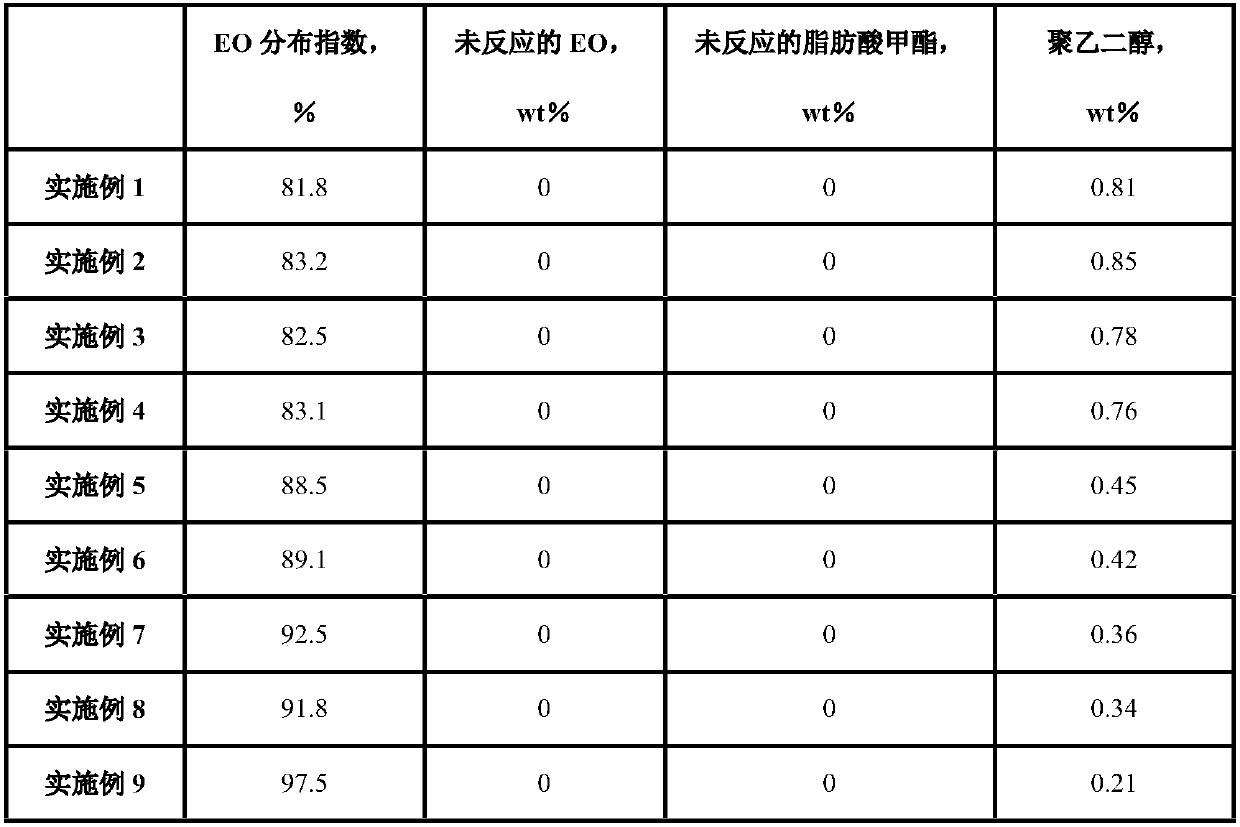

Examples

Embodiment 1

[0037] Weigh 40g of layered sodium phosphate antimonate respectively (the layer spacing is ) and 10g of anhydrous calcium acetate and 50g of N-hydroxysuccinimide were added to 800g of pure water, hydrothermally treated at 85°C and 800rpm stirring speed for 4 hours, and left standstill for 10 hours; then dried at 110°C for 18 hours, tableted, broken , After sieving, take a 100-200 mesh sample as a catalyst.

[0038] 0.5 g of the above-mentioned catalyst was added to 100 g of methyl laurate, and put into a 1 L autoclave while stirring; the autoclave was heated to 80° C., vacuum-dried for 10 min, replaced with high-purity nitrogen three times, and heated to 150° C., Introduce EO, keep the temperature between 150 and 180 ° C, and keep the pressure at 0.4 MPa, react for 30 min to the amount of EO added to be 144 g, age for 30 min, cool to room temperature to release the material, weigh 244 g, and obtain an average EO addition number of 7. Methyl laurate ethoxylate. The content o...

Embodiment 2

[0040] Weigh the layered sodium phosphate antimonate (the interlayer spacing is ) and 10g of anhydrous calcium acetate and 50g of N-hydroxymaleimide were added to 800g of pure water, hydrothermally treated at 85°C and 800rpm stirring speed for 4 hours, and left to stand for 10 hours; then dried at 110°C for 18 hours, pressed. After flakes, crushing and sieving, 100-200 mesh samples are taken as catalysts.

[0041]0.5 g of the above-mentioned catalyst was added to 100 g of methyl laurate, and put into a 1 L autoclave while stirring; the autoclave was heated to 80° C., vacuum-dried for 10 min, replaced with high-purity nitrogen three times, and heated to 150° C., Introduce EO, keep the temperature between 150 and 180 ° C, and keep the pressure at 0.4 MPa, react for 30 min to the amount of EO added to be 144 g, age for 30 min, cool to room temperature to release the material, weigh 244 g, and obtain an average EO addition number of 7. Methyl laurate ethoxylate. The content of ...

Embodiment 3

[0043] Weigh 40g of layered sodium phosphate antimonate respectively (the layer spacing is ) and 10g of anhydrous barium acetate and 50g of N-hydroxysuccinimide were added to 800g of pure water, hydrothermally treated at 85 ° C and 800 rpm stirring speed for 4 hours, and allowed to stand for 10 hours; then dried at 110 ° C for 18 hours, tableted, After crushing and sieving, take 100-200 mesh samples as catalyst.

[0044] 0.5 g of the above-mentioned catalyst was added to 100 g of methyl laurate, and put into a 1 L autoclave while stirring; the autoclave was heated to 80° C., vacuum-dried for 10 min, replaced with high-purity nitrogen three times, and heated to 150° C., Introduce EO, keep the temperature between 150 and 180 ° C, and keep the pressure at 0.4 MPa, react for 30 min to the amount of EO added to be 144 g, age for 30 min, cool to room temperature to release the material, weigh 244 g, and obtain an average EO addition number of 7. Methyl laurate ethoxylate. The con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com