Screening machine for tea leaf processing

A sieving machine and tea technology, applied in the direction of sieving, separating solids from solids with airflow, solid separation, etc., can solve problems such as surface damage, inability to classify and sieve tea leaves, small vibration range and vibration amplitude, etc., to achieve Strengthen the screening force, increase the vibration range, and the effect of strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

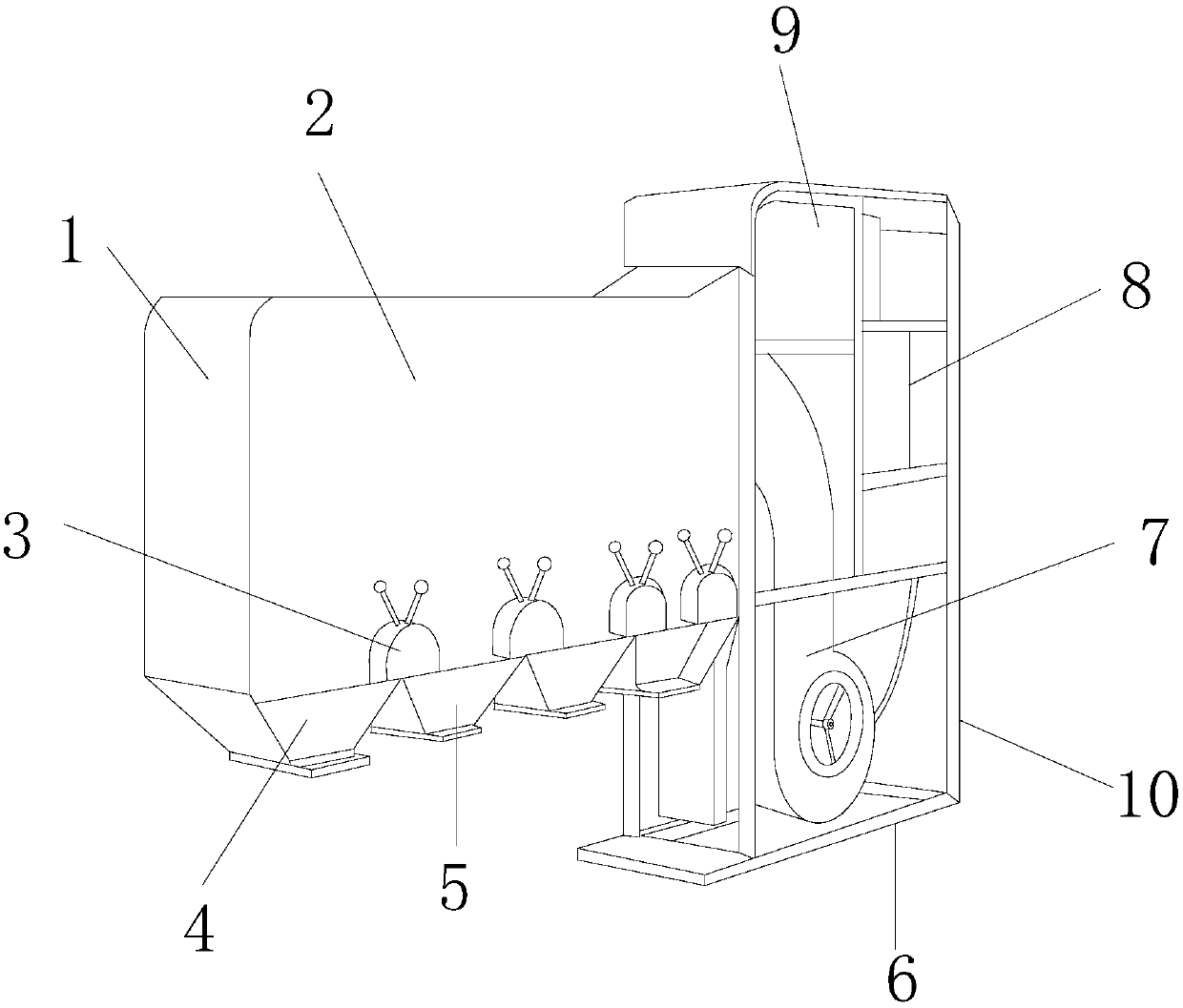

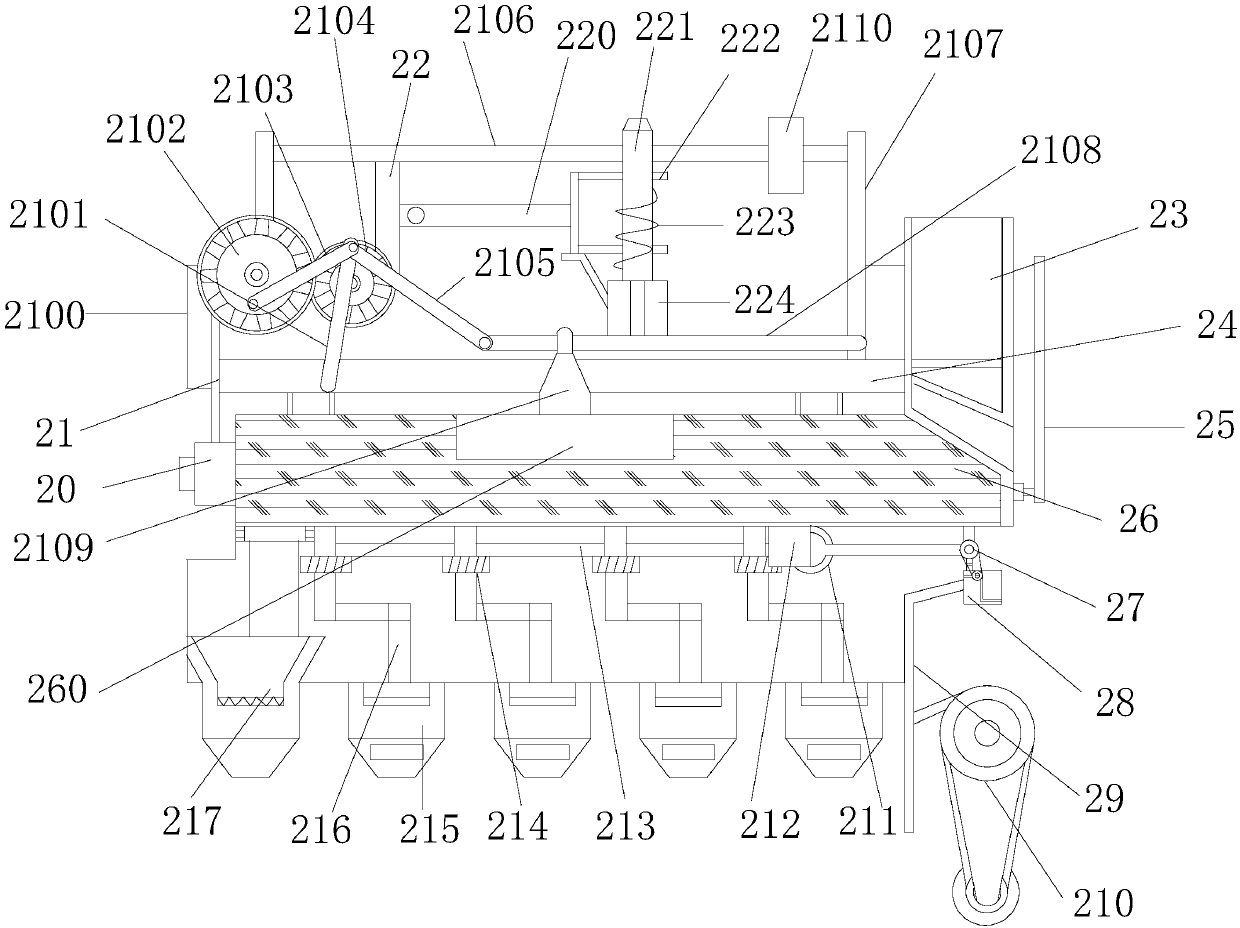

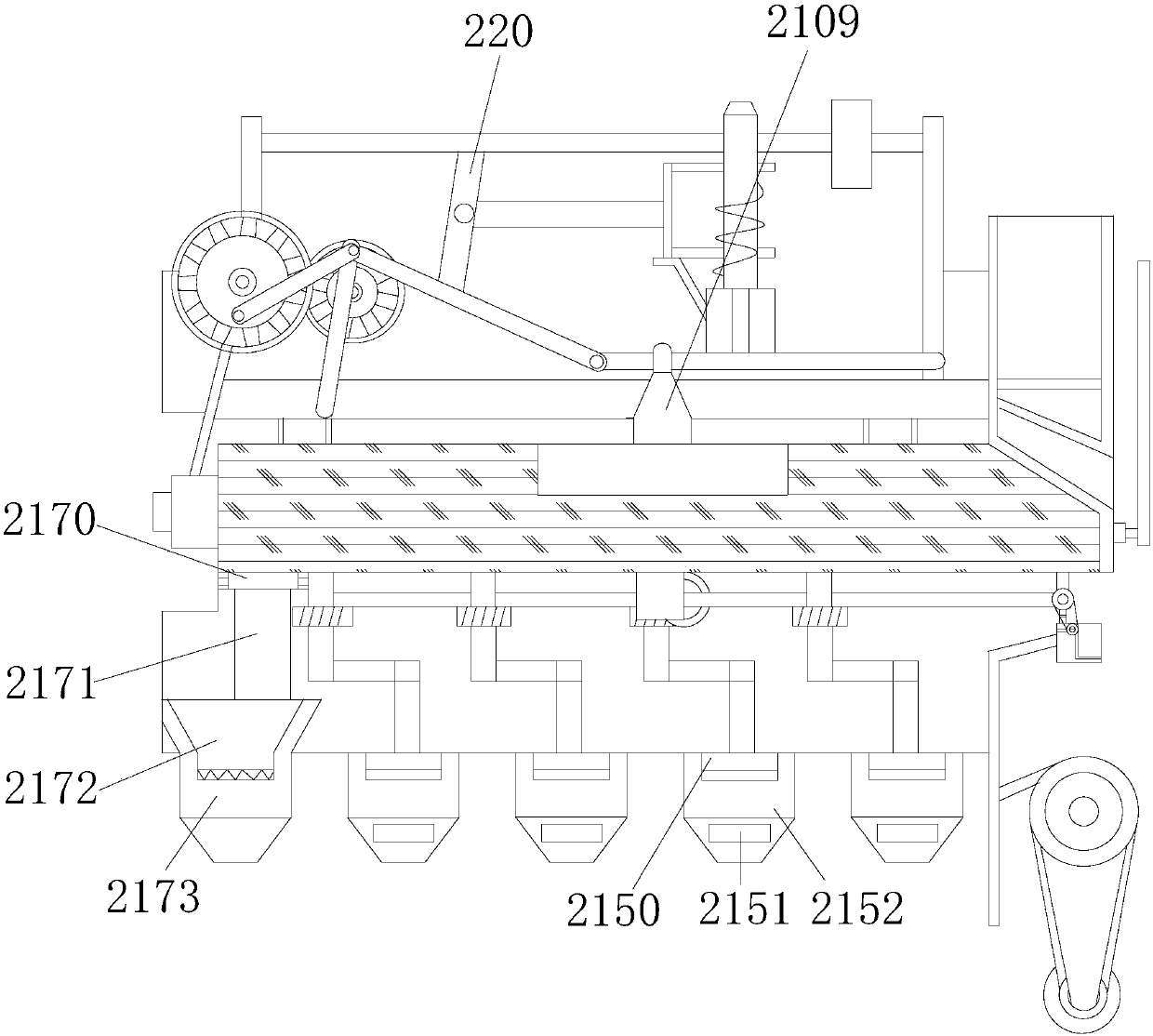

[0023] see Figure 1 to Figure 3, the present invention provides a screening machine for tea processing, the structure of which includes a screening box 1, a telescopic mobile grading and screening mechanism 2, a screen holder 3, a chip discharge bucket 4, a tea discharge hopper 5, a base 6, and a dust removal fan 7. Transmission box 8, feeding box 9, frame 10, the dust removal fan 7 is fixed on the base 6 and connected to the screening box 1, the base 6, frame 10 are welded and perpendicular to each other, the transmission Box 8 is installed on the right side of the frame 10, and the top of the transmission box 8 is provided with a blanking box 9, and the screening box 1 is installed at the side end of the blanking box 9 and connected to the frame 10, and the screening box 1 1 is equipped with a telescopic mobile grading and screening mechanism 2. The tea outlet hopper 5 is movable and installed at the bottom of the screening box 1. There are four tea outlet hoppers 5. The ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com