Transmission shaft head unit

A head unit and drive shaft technology, applied in the field of machinery, can solve the problems of unstable connection relationship, increased labor costs, structural deformation, etc., and achieve the effects of instant cooling of the connection relationship, reasonable overall design, and extended service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further explained below in conjunction with the accompanying drawings and embodiments.

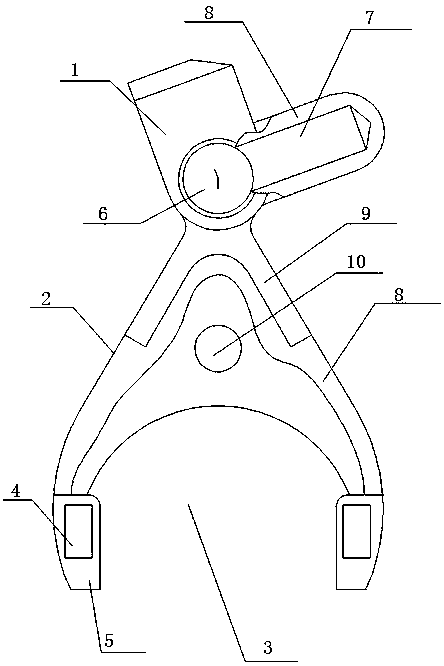

[0013] Such as figure 1 As shown, a transmission shaft head unit includes a limit rotation unit 1 and a clamp unit 2 movably connected with the limit rotation unit 1, the clamp unit 2 is a clamp unit with an arc-shaped opening 3, and the arc-shaped The opening 3 is symmetrically provided with a magnetic clamping block 4, and the magnetic clamping block 4 is wrapped with an elastic wear-resistant layer 5. The position-limiting rotation unit 1 includes a rotating shaft 6 and a rotating block 7 adapted to the rotating shaft 6. The limit rotation unit 1 and the clamp unit 2 are provided with a cooling cavity 8, and the cooling cavity 8 is provided with cooling liquid. A reinforcement piece 9 is provided at the joint between the limit rotation unit 1 and the clamp unit 2 . The rotating block 7 is a rotating block made of magnetic material. The clamp unit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com