Carrier rocket sub-stage recycling system and method

A launch vehicle and recovery system technology, applied in the field of aircraft systems, can solve problems such as increasing risks, changing the aerodynamic shape of the rocket, reducing the payload of the launch vehicle sub-stage, etc., achieving the effect of reducing the weight of the rocket body and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the purpose, technical solution and advantages of the present invention clearer, the following will further describe the public implementation manners of the present invention in detail with reference to the accompanying drawings.

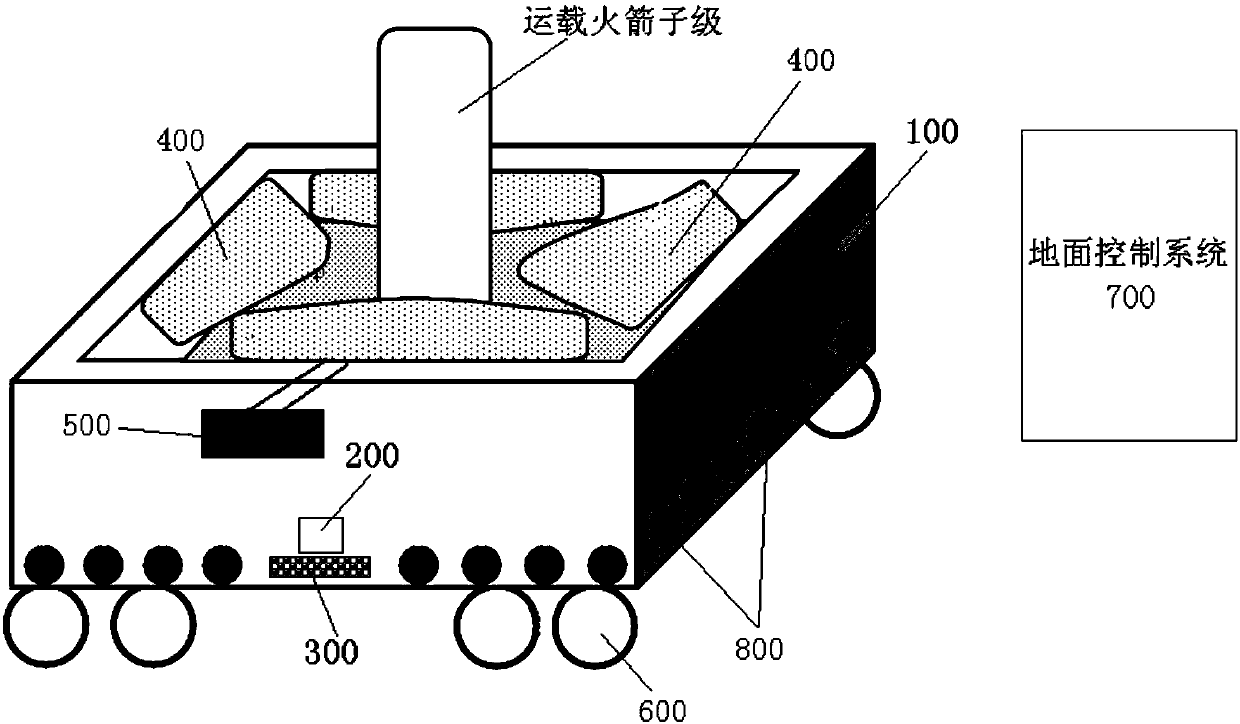

[0044] refer to figure 1 , shows a schematic structural view of a launch vehicle sub-stage recovery system in an embodiment of the present invention. In this embodiment, the launch vehicle sub-stage recovery system may include: a recovery box 100 , a detection device 200 , a signal transceiver device 300 , a plurality of airbags 400 , an inflator 500 , a moving mechanism 600 and a ground control system 700 . The launch vehicle sub-stage recovery system, as a ground device for launch vehicle sub-stage recovery, can be arranged at any appropriate location on land, ship deck, etc., to realize the recovery of the launch vehicle sub-stage. Wherein, the meaning of the launch vehicle sub-stage may be the rocket core stage or the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com