Glass support frame

A support frame and glass technology, which is applied to the external frame, packaging of vulnerable items, packaging, etc., can solve the problems of glass breaking, loosening, affecting glass safety, etc., and achieve the effects of easy manufacturing, reasonable and simple structure, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

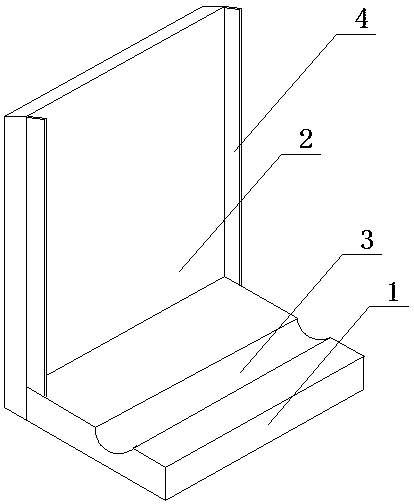

[0015] A glass support frame includes a bottom frame 1 and a leaning stand 2, the bottom frame 1 is provided with a limiting groove 3, and the limiting groove 3 is a semicircular limiting groove. A rubber layer is arranged in the defined groove 3, and the thickness of the rubber layer in the defined groove 3 is 1CM. The leaning stand 2 is provided with a rubber layer, the thickness of the rubber layer is 1CM, and both sides of the leaning stand 2 are provided with baffles 4, and the baffles 4 are higher than the leaning stand 1CM. The bottom of the underframe 1 is provided with a pulley with an anti-slip device.

Embodiment 2

[0017] A glass support frame includes a bottom frame 1 and a leaning stand 2, the bottom frame 1 is provided with a limiting groove 3, and the limiting groove 3 is a semicircular limiting groove. A rubber layer is arranged in the defined groove 3, and the thickness of the rubber layer in the defined groove 3 is 1CM. The leaning stand 2 is provided with a rubber layer, the thickness of the rubber layer is 1CM, and both sides of the leaning stand 2 are provided with baffles 4, and the baffles 4 are higher than the leaning stand 3CM. The bottom of the underframe 1 is provided with a pulley with an anti-slip device.

Embodiment 3

[0019] A glass support frame includes a bottom frame 1 and a leaning stand 2, the bottom frame 1 is provided with a limiting groove 3, and the limiting groove 3 is a semicircular limiting groove. A rubber layer is arranged in the defined groove 3, and the thickness of the rubber layer in the defined groove 3 is 2CM. The leaning stand 2 is provided with a rubber layer, the thickness of the rubber layer is 2CM, and both sides of the leaning stand 2 are provided with a baffle plate 4, and the baffle plate 4 is higher than the leaning stand 5CM. The bottom of the underframe 1 is provided with a pulley with an anti-slip device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com