Novel method for preparing synthetic capsaicin

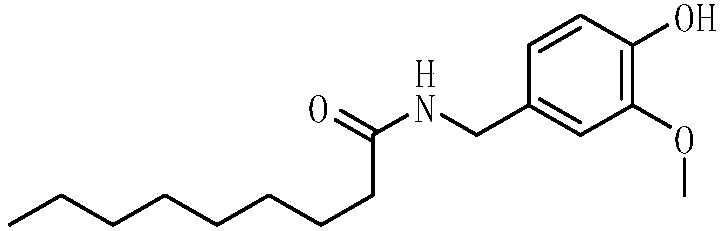

A technology for synthesizing capsaicin and a new method, applied in the field of preparing synthetic capsaicin, can solve the problems of complicated post-processing, low reaction conditions, low yield and the like, and achieve the effects of simple and easy processing method, simple operation process and reduction of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

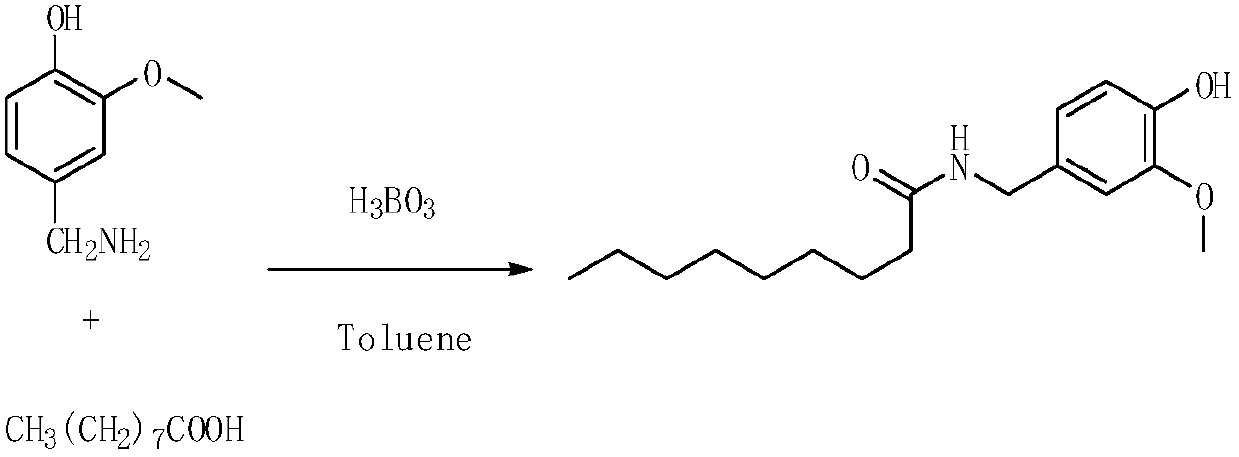

Embodiment 1

[0028] In a three-necked 500mL flask, add 30.0g (0.196mol) of vanillinamine, 31.0g (0.196mol) of n-nonanoic acid, 300mL of toluene, and 0.6g (9.8mmol) of boric acid. One of the three-necked flasks is equipped with a thermometer and the other is equipped with an oil-water separator. + Reflux condenser (put the oil-water separator into the reaction bottle, and then install the reflux condenser on the oil-water separator), the other port is closed, start stirring, heat up to 130°C for 8 hours, cool down to room temperature after the reaction, add 50mL Wash twice with water (to extract boric acid), dry with anhydrous sodium sulfate, and use a rotary evaporator to recover toluene under reduced pressure at 60°C until the distilled toluene is 2 / 3 of the original volume, stop the recovery under reduced pressure, and transfer the remaining liquid to Stir and crystallize at -20°C for 3 h in a low-temperature constant temperature reactor, filter, wash the obtained crystals with toluene, a...

Embodiment 2

[0034] In a three-necked 500mL flask, add 30.0g (0.196mol) of vanillinamine, 31.0g (0.196mol) of nonanoic acid, 300mL of toluene, and 1.2g (19.6mmol) of boric acid. One of the three-necked flasks is equipped with a thermometer and the other is equipped with an oil-water separator. + Reflux condenser, the other port is closed, start stirring, heat up to 130°C for 8 hours, cool down to room temperature after the reaction, add 50mL water to wash twice, dry with anhydrous sodium sulfate, use a rotary evaporator to reduce pressure at 60°C Recover toluene until the distilled toluene is 2 / 3 of the original volume, stop the recovery under reduced pressure, transfer the remaining liquid to a low-temperature constant temperature reactor, stir and crystallize at -20°C for 3 hours, filter, wash the obtained crystals with toluene, and drain to obtain a white Powder solid (synthetic capsaicin) 48.0g, yield 83.4%, HPLC purity 98.7%.

Embodiment 3

[0036] In a three-necked 500mL flask, add 30.0g (0.196mol) of vanillin amine, 31.0g (0.196mol) of n-nonanoic acid, 240mL of toluene, and 0.6g (9.8mmol) of boric acid. One of the three-necked flasks is equipped with a thermometer and the other is equipped with an oil-water separator. + Reflux condenser, the other port is closed, start stirring, heat up to 130°C for 8 hours, cool down to room temperature after the reaction, add 50mL water to wash twice, dry with anhydrous sodium sulfate, use a rotary evaporator to reduce pressure at 60°C Recover toluene until the distilled toluene is 2 / 3 of the original volume, stop the recovery under reduced pressure, transfer the remaining liquid to a low-temperature constant temperature reactor, stir and crystallize at -20°C for 3 hours, filter, wash the obtained crystals with toluene, and drain to obtain a white Powder solid (synthetic capsaicin) 46.8g, yield 81.5%, HPLC purity 98.5%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap