Fabric having motion following ability

A followability and fabric technology, applied in the field of warp knitted fabrics, can solve the problems of motion followability of non-elastic fabrics, and achieve the effect of maintaining wearing comfort, lasting elastic effect, and preventing muscle vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

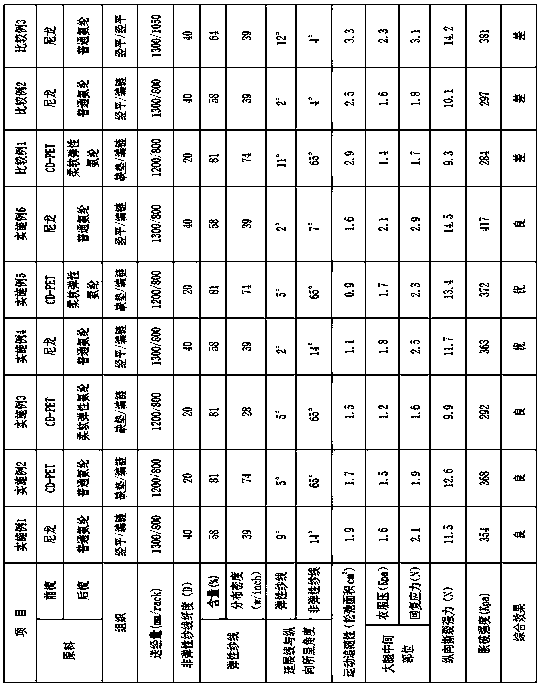

Embodiment 1

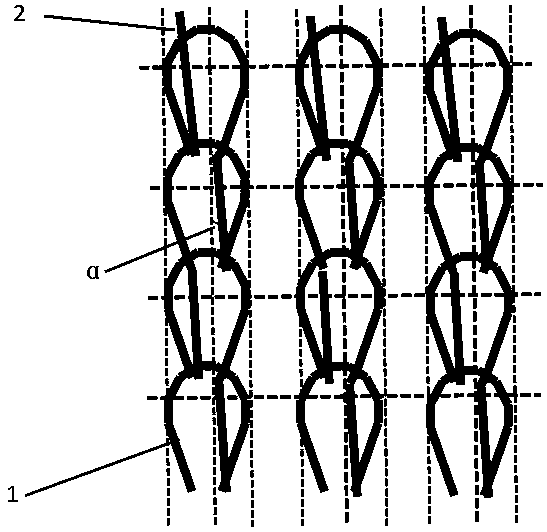

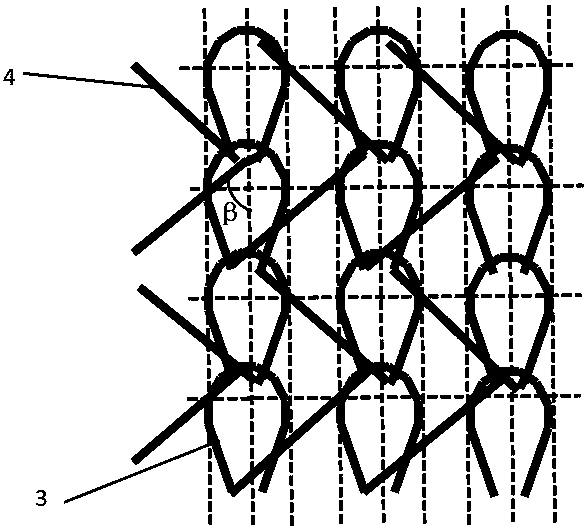

[0053] On the RSE4 Raschel warp knitting machine (machine number E32, machine width 136 inches), 40D-34f-nylon FDY is selected as the front comb yarn, 100D ordinary spandex (manufactured by Huafeng Company) is used as the back comb yarn, and the front comb The gray fabric is obtained by weaving the warp plain / knitting chain weaving across 2 stitches and the rear comb spanning 1 stitch, and then through scouring and dyeing to obtain the motion-following fabric of the present invention, see Table 1 for details.

[0054] Among them, scouring: caustic soda 2g / L, scouring agent 2g / L, 95℃×20min, liquor ratio 1:20; dyeing: 95℃×30min, reduction cleaning: 80℃×20min.

Embodiment 2

[0056]On the HKS4 high-speed tricot machine (machine number E32, machine width 136 inches), 20D-12f- cationic dyeable polyester FDY is used as the front carding yarn, and 140D ordinary spandex (manufactured by Hyosung) is used as the back carding yarn yarn, the front comb spans 1 to 2 stitches, and the back comb spans 1 stitch to weave gray cloth, and then through scouring and dyeing, the fabric fabric with motion following property of the present invention is obtained. For details, see Table 1.

[0057] Among them, scouring: caustic soda 2g / L, scouring agent 2g / L, 95℃×20min, liquor ratio 1:20; dyeing: 120℃×60min, reduction cleaning: 80℃×20min.

Embodiment 3

[0059] On the HKS4 high-speed tricot machine (machine number E28, machine width 170 inches), 20D-12f- cationic dyeable polyester FDY is selected as the front comb yarn, and 140D soft elastic spandex (manufactured by TORAY OPELONTEX company) is used as the back comb The yarn is obtained by braiding the lack of cushion / knitting chain structure with the front comb spanning 1-2 stitches and the rear comb spanning 1 stitch, and then scouring and dyeing to obtain the sports-following fabric of the present invention, see the table for details 1, wherein, scouring, dyeing conditions are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com