Steel composite material anti-collision facility

A composite material and anti-collision technology, applied in shipping equipment, bridge construction, bridge parts, etc., can solve problems such as increased cost, weak anti-collision ability of bridge columns, and bridge damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

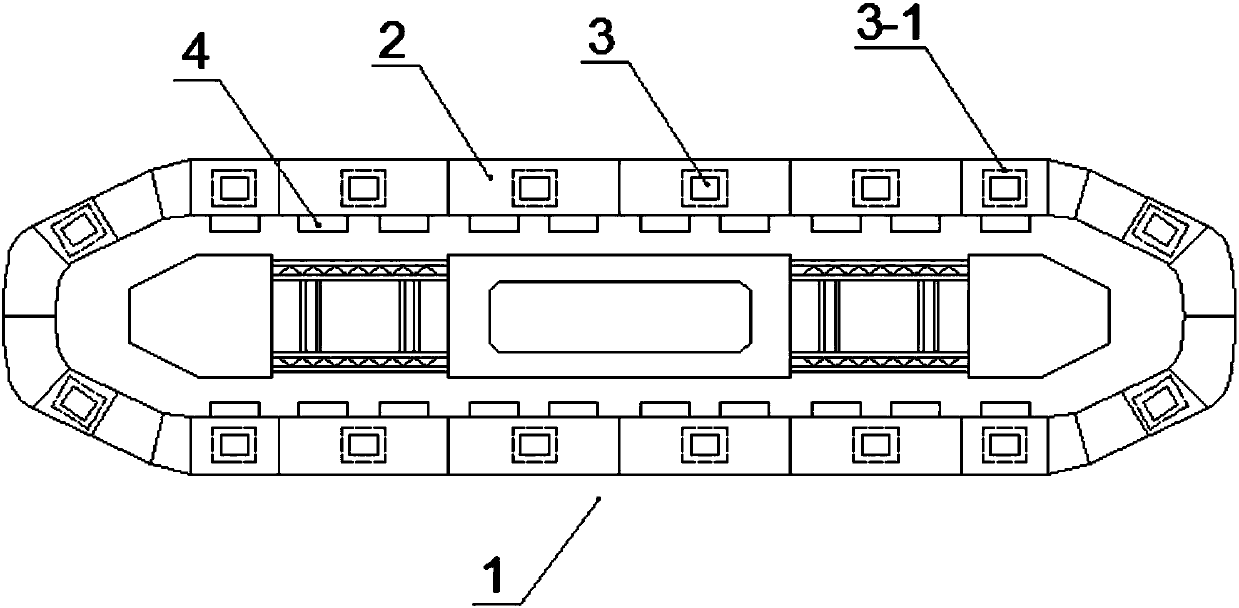

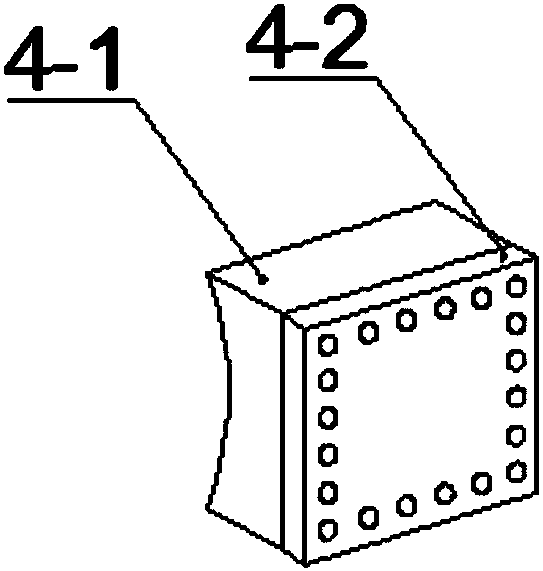

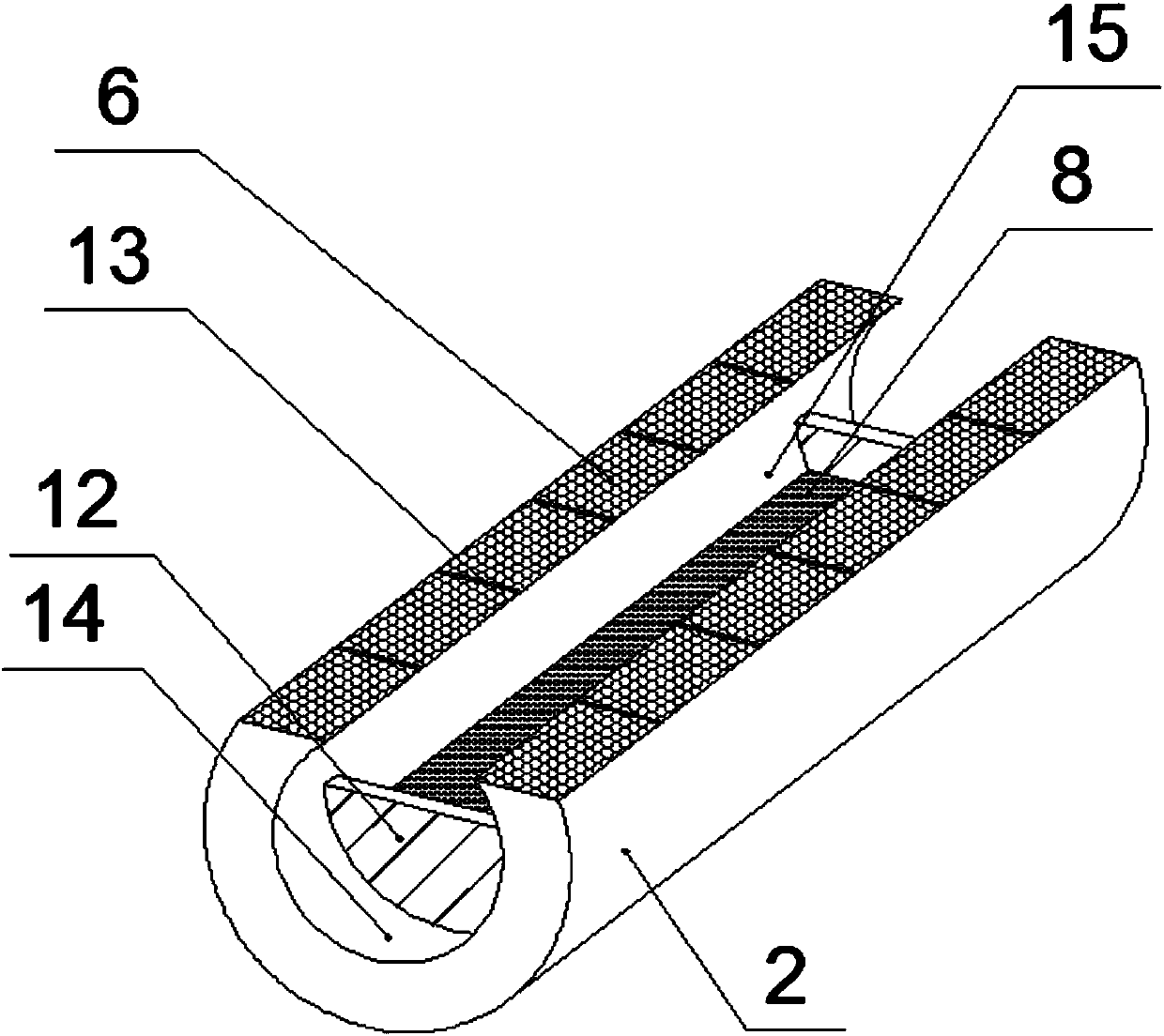

[0020] Such as figure 1 and Figure 4 As shown, a steel composite material anti-collision facility includes an anti-collision ring and an energy-dissipating filler; the anti-collision ring 1 is composed of several segments 2 connected end to end, and the anti-collision ring 1 is in the shape of a runway, and the segments The segments 2 are connected by connecting flanges 9, the segment 2 is in the shape of a ring column, and the energy-dissipating filler 6 is installed inside the segment 2, and the energy-dissipating partition 13 evenly separates the energy-dissipating filler 6, so The inner wall of the segment 2 is pasted with an internal reinforced steel cylinder 11 . Wherein, the present invention takes the anti-collision ring 1 as the main body, and the anti-collision ring 1 is in the shape of a racetrack, and the segments 2 at the left and right ends are curved. Since both sides of the bridge pier to be protected are curved surfaces, in order to enhance the fitting degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com