Gear case ventilation structure and gear case

A ventilation structure and gear box technology, applied in belts/chains/gears, transmission parts, mechanical equipment, etc., can solve the problems of easy dust contamination, blocked breathing passages, etc., and achieve the effects of easy maintenance, improved waterproofing, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

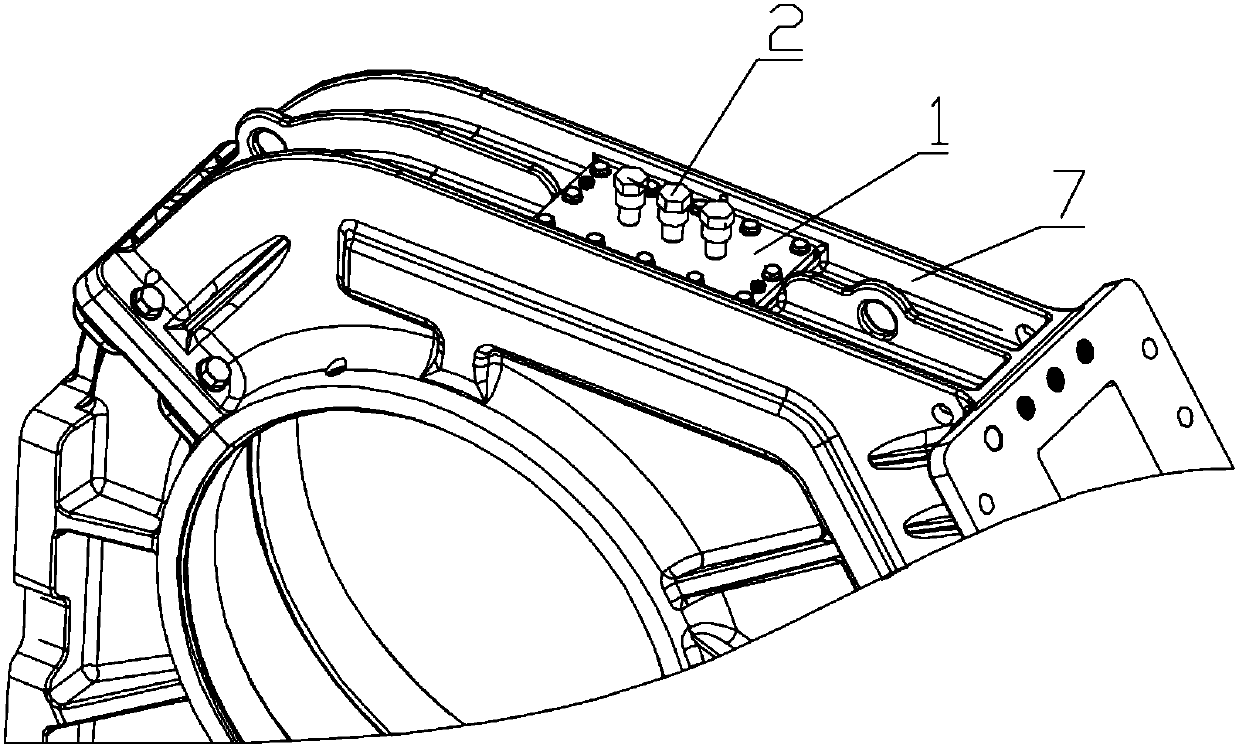

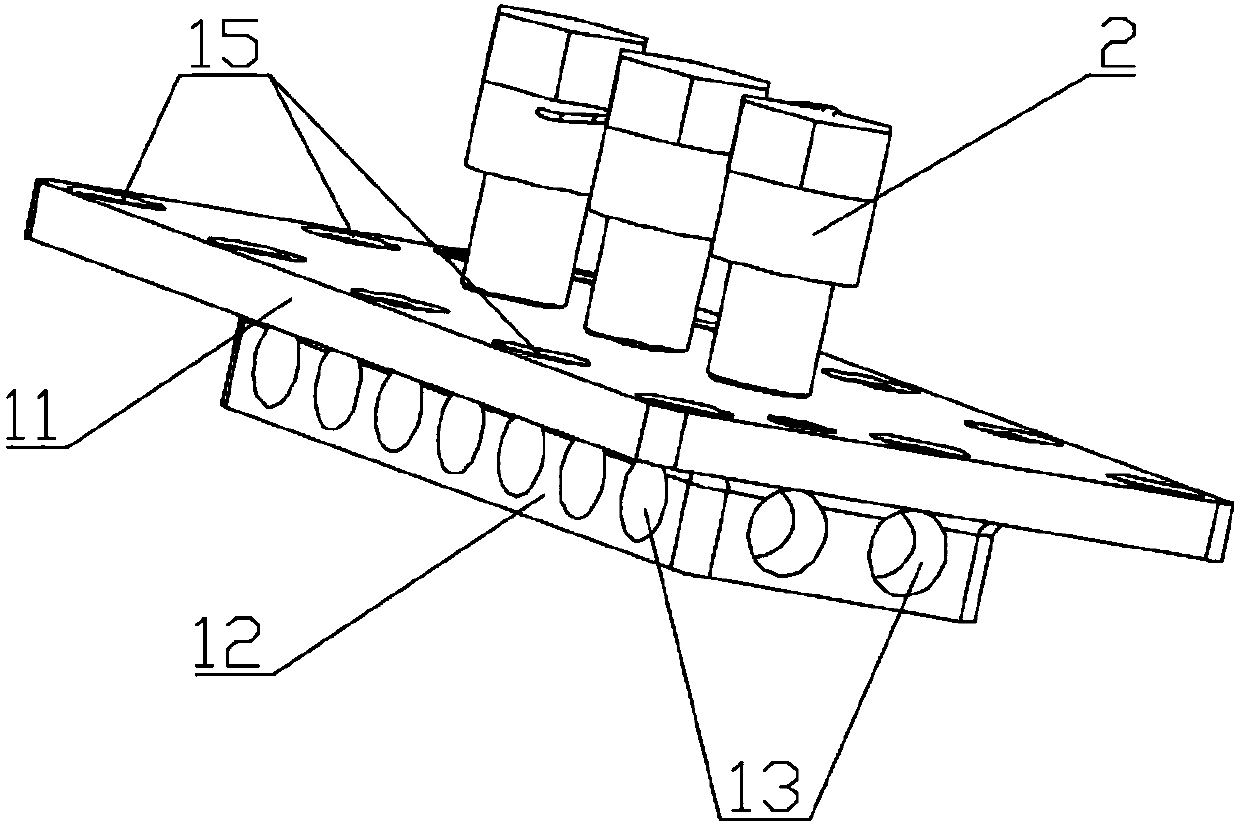

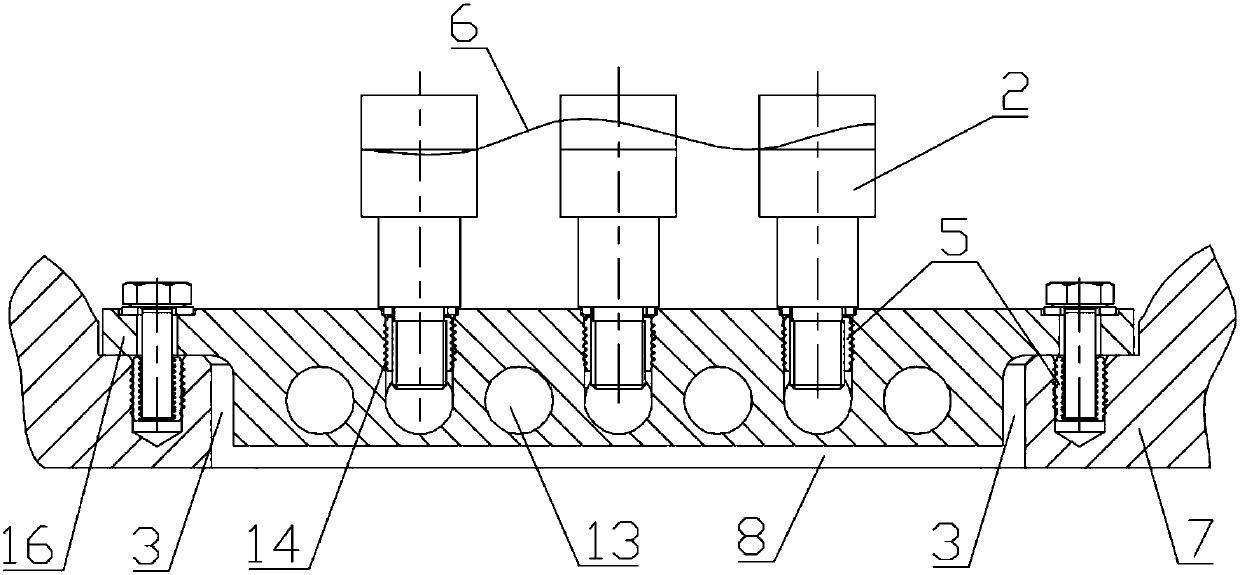

[0021] see Figure 1-5 , a gear box ventilation structure, which includes a ventilation cover 1 and a respirator 2 arranged on the ventilation cover 1, the ventilation cover 1 includes an upper cover 11 and a lower cover 12, the The upper cover plate 11 covers the lower cover plate 12, and the area where the upper cover plate 11 protrudes from the lower cover plate 12 is an installation skirt 16, and the ventilation cover plate 1 is installed on the On the gear box 7, the upper cover plate 11 covers the cover plate installation hole 8 on the gear box 7, the lower cover plate 12 is located in the cover plate installation hole 8 and the side of the lower cover plate 12 is in contact with the There is a ventilation gap 3 between the inner surfaces of the cover mounting holes 8, the lower cover 12 is provided with a ventilation hole 13 penetrating the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com