Device for measuring heights of coal in coke oven carbonization chambers

A technology for carbonization chamber and coal material, applied in the field of coking coke oven, can solve the problems of easy offset, measurement blind area and reading error, unable to reflect the accumulation and distribution of coal material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

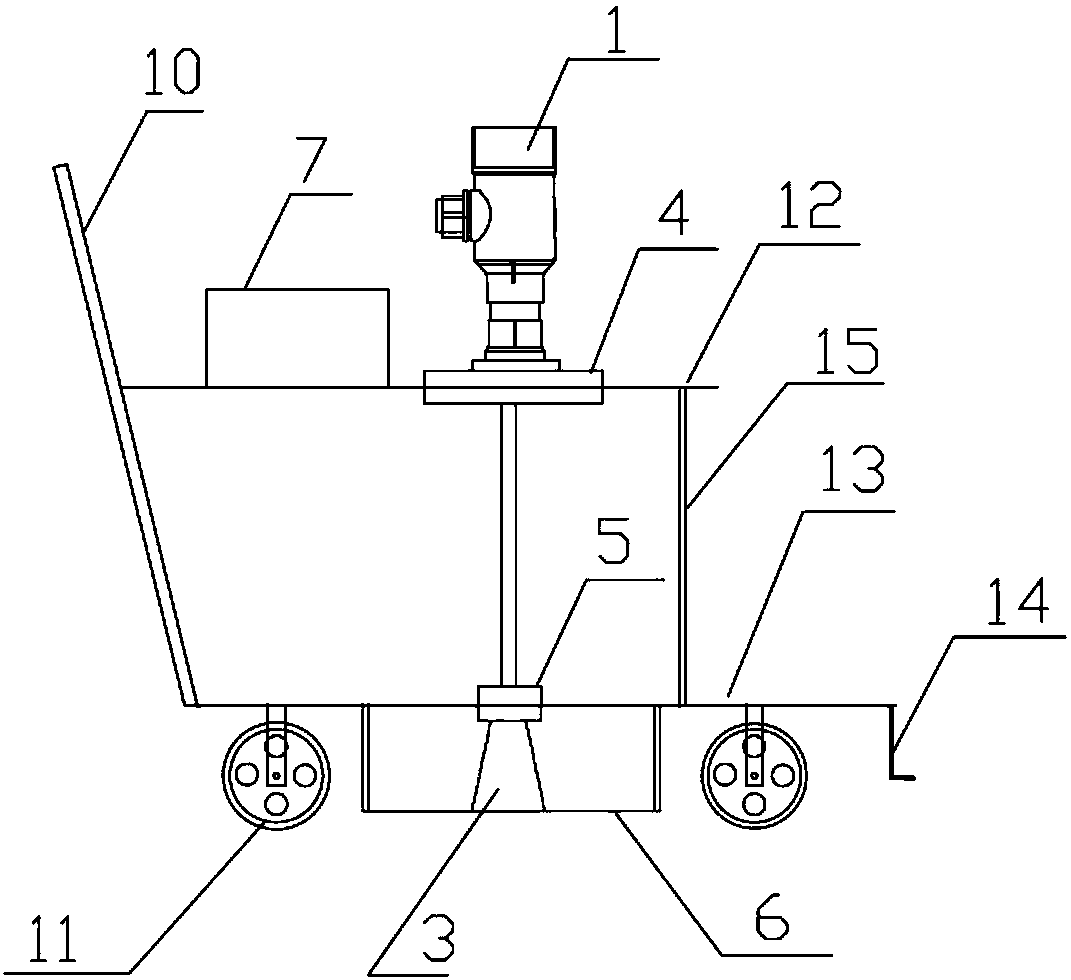

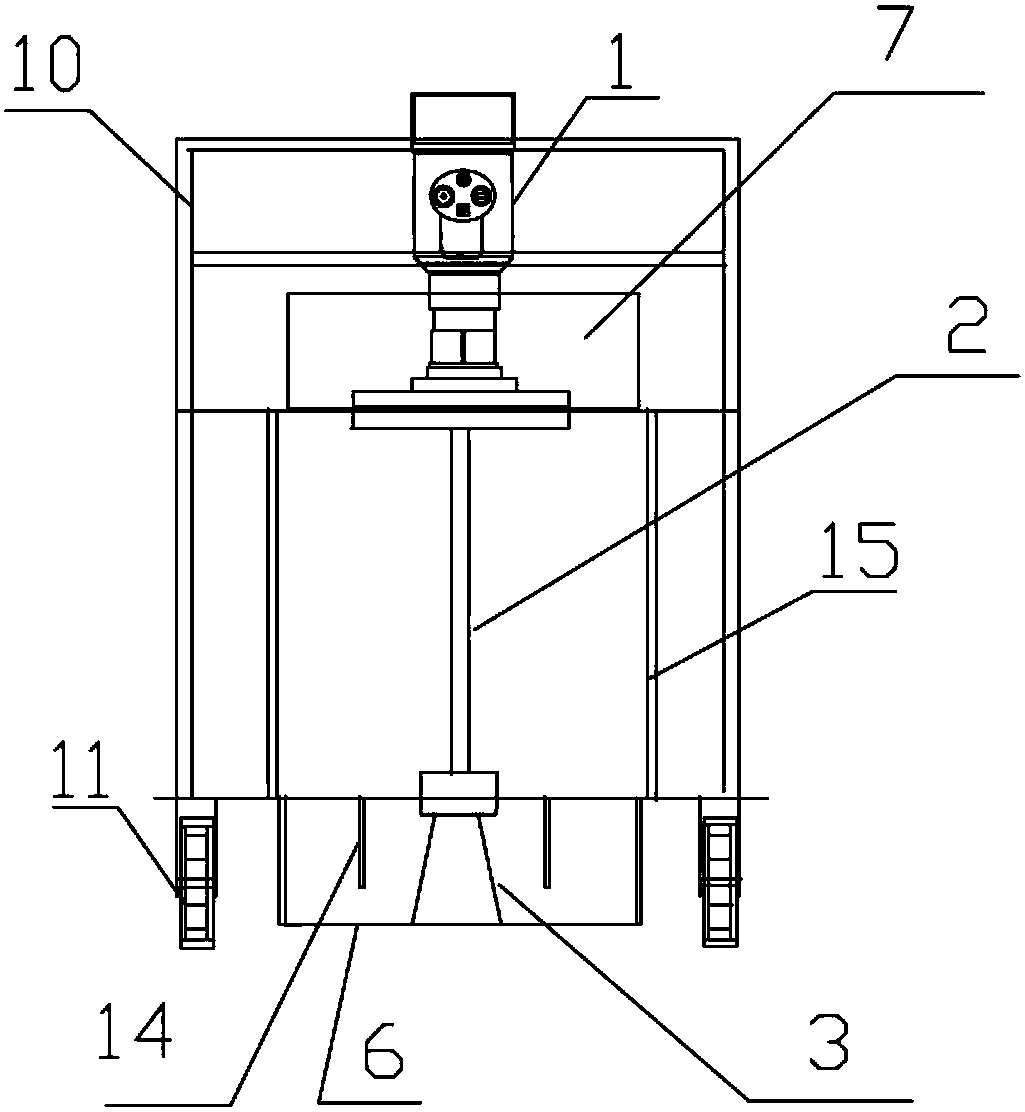

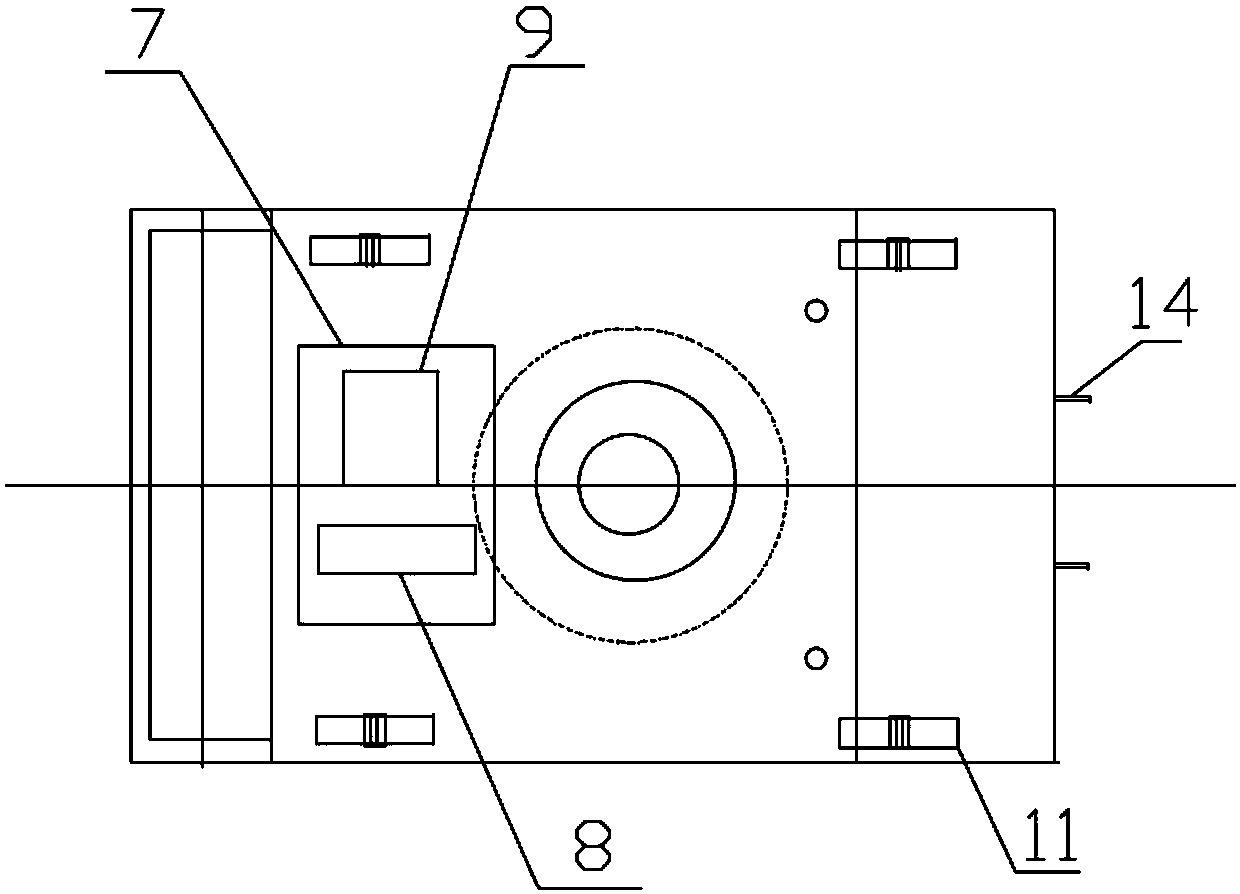

[0029] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

[0030] Such as Figure 1 to Figure 5 As shown, the device for measuring the height of the coal in the coke oven carbonization chamber includes a vehicle frame and a radar material gauge installed on the vehicle frame for measuring the height of the coal material in the carbonization chamber. The vehicle frame is provided with a control box 7 connected to the radar material gauge. , the control box 7 is a rechargeable mobile power supply 8 and a paperless recorder 9, and both the rechargeable mobile power supply and the paperless recorder are connected to the radar material meter.

[0031] Vehicle frame comprises upper floor steel plate 12 and lower floor steel plate 13 and is located at the steel pipe support 15 between upper floor steel plate and lower floor steel plate, and a side of upper fl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap