High-voltage cable oscillatory wave partial discharge test system

A high-voltage cable and testing system technology, applied in the direction of testing dielectric strength, measuring electricity, measuring devices, etc., can solve the problems of no tightening measures, affecting installation efficiency, and unstable installation, and achieves high connection firmness and structure. Simple and effective in eliminating security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

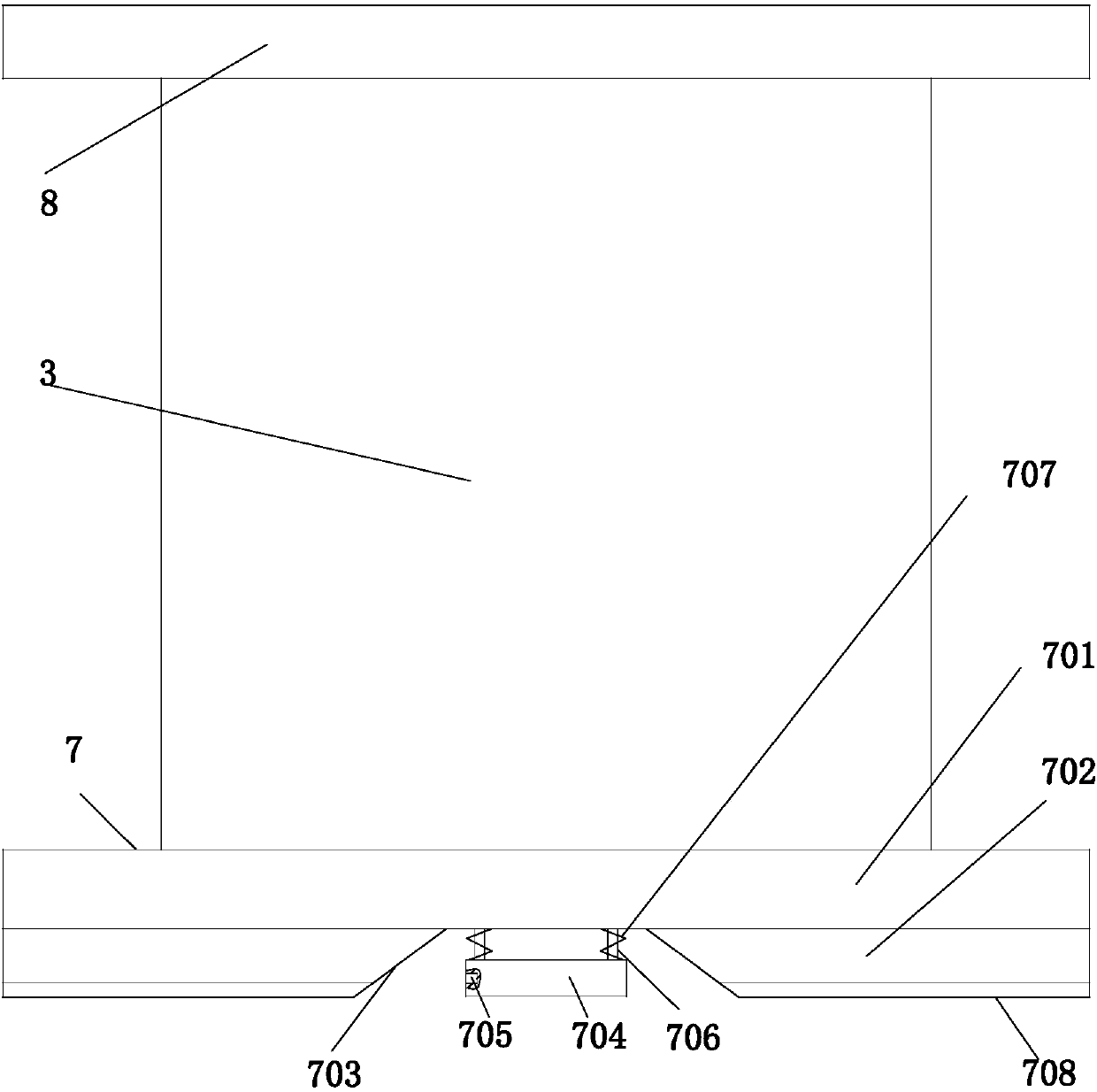

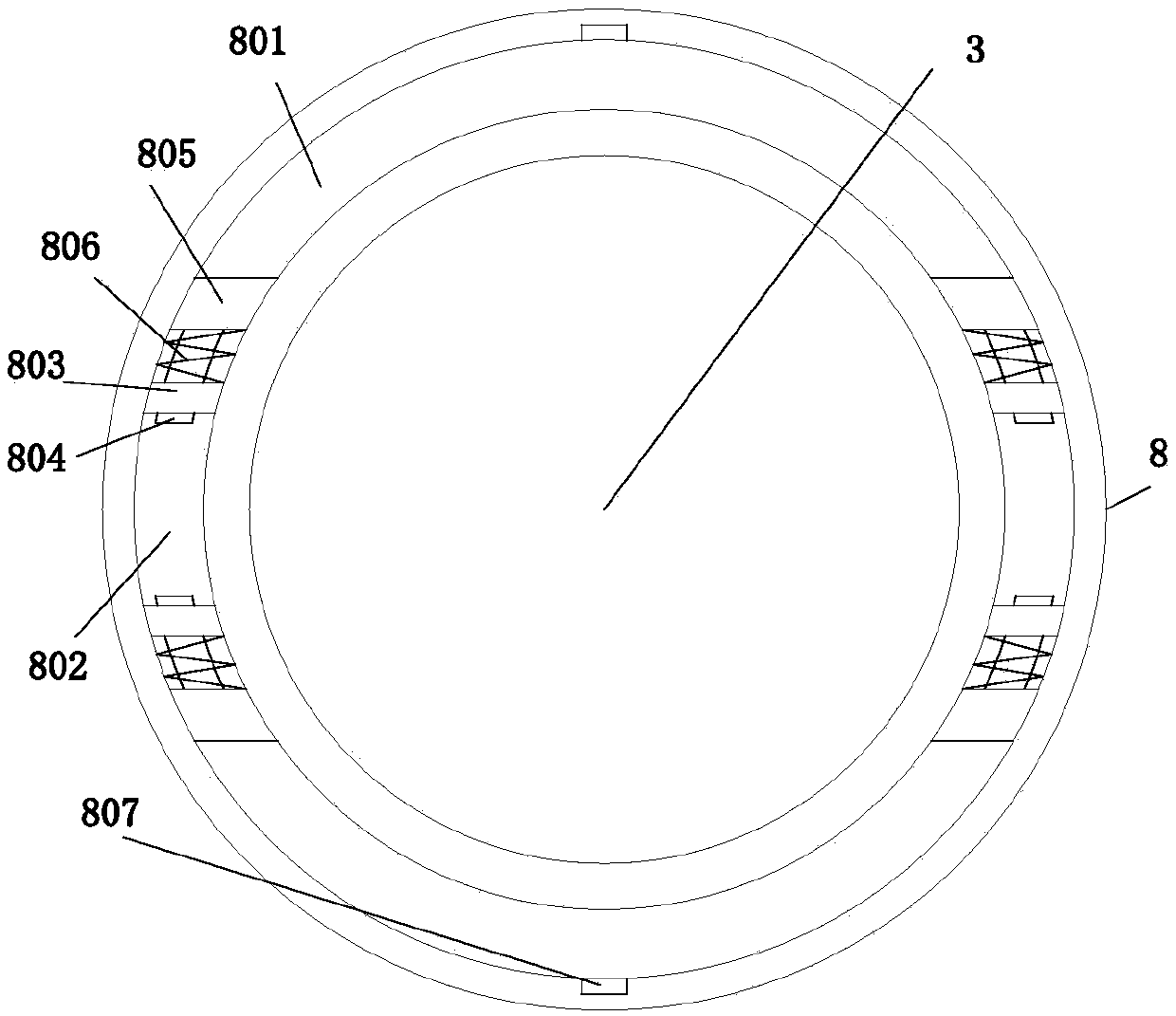

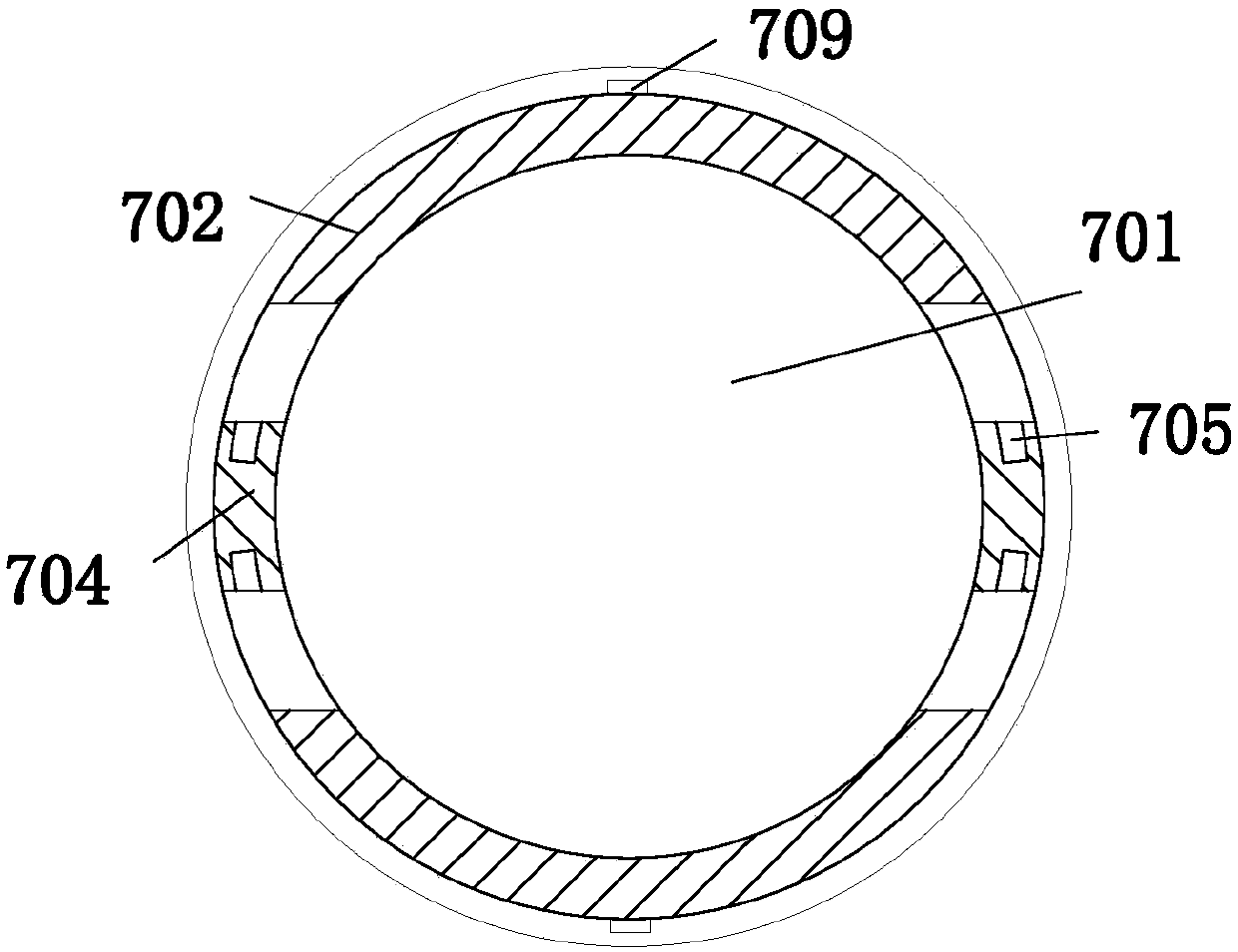

[0021] Example. A high-voltage cable oscillatory wave partial discharge test system, which is composed of Figure 1 to Figure 6 As shown, it includes a high-voltage DC power supply 1, a high-voltage switch 2, a high-voltage reactor 3, a capacitor voltage divider 4, a data acquisition and analysis unit 5, and a partial discharge coupling unit 6. The bottom of the high-voltage reactor 3 is provided with a base 7, and the high-voltage reactor The top of the device 3 is provided with a card seat 8; the base 7 includes a base 701 fixed to the high voltage reactor 3, and two symmetrically arranged ring-shaped fixing seats 702 are arranged under the base 701, and the two ends of the ring-shaped fixing seat 702 are Inclined surface structure 703, limit plate 704 is arranged between annular fixed seat 702, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com